9

6. Gently tap the cylinder head (15), cooling plate (14) and

valve plate assembly (13) with a soft mallet to break

the gasket seals. Then separate the cylinder head (15)

from the cooling plate (14) and valve plate assembly

(13), and remove and discard the two head gaskets (4)

between them.

CRANKCASE FRONT COVER

1. Remove the cover (10) from the front of the crankcase.

Use a sharp fl at head screw driver or a scraper. Place

the edge under the lip along the outside diameter of

the cover. Pry the cover from the cast surface until the

cover can be removed.

REAR END COVER

1. Note: There are two cap screws (7) used to retain the

end cover to the crankcase. There are two longer cap

screws (not shown in Figure 9) that are used to retain

the auxiliary drive unit (i.e. hydraulic pump) via the end

cover and torqued into the crankcase. If the auxiliary

drive unit has already been removed, these two cap

screws are no longer present on the end cover.

Refer

to Figure 9 to see location of the cap screws (7) in the

end cover.

2. Remove the two end cover cap screws (7) that secure

the rear end cover to the crankcase.

3. Remove the rear end cover (8) from the crankcase.

Remove and discard the o-ring (9) from the end cover

(8).

CLEANING OF PARTS

GENERAL

All parts should be cleaned in a good commercial grade of

solvent and dried prior to inspection.

CRANKCASE

1. Carefully remove all sealant gasket material adhering

to the machined face of the crankcase.

See Figure

3.

Make certain not to scratch or mar the mounting

surface. Note: Keep the crankcase (11) opening

covered to prevent any of the sealant material from

entering. Repeat this process on the engine mounting

face as well. Follow the instructions contained in the

vehicle maintenance manual in lieu of the instructions

and procedures presented in this manual.

2. Carefully remove all gasket material adhering to the

deck (top) of the crankcase. Remove any carbon

deposits from the deck of the crankcase. Make certain

not to scratch or mar the gasket surfaces.

CYLINDER HEAD, COOLING PLATE & VALVE

PLATE ASSEMBLY

1. Carefully remove all gasket material adhering to the

cylinder head (15), cooling plate (14) and valve plate

assembly (13). Make certain not to scratch or mar the

gasket surfaces. Pay particular attention to the gasket

surfaces of the cylinder head and cooling plate.

2. Remove carbon deposits from the discharge and inlet

cavities of the cylinder head, cooling plate and valve

plate assembly. The cavities must be open and clear.

Make certain not to damage the parts,while cleaning.

3. Remove rust and scale from the cooling cavities and

passages in the cylinder head, cooling plate and valve

plate assembly and use shop air to clear debris from

the passages.

4. Check the threads in all cylinder head ports for

galling (e.g. abrasion, chafi ng). Minor thread chasing

(damage) is permitted.

INSPECTION OF PARTS

CYLINDER HEAD, COOLING PLATE AND VALVE

PLATE ASSEMBLY

1. Carefully inspect the head gasket surfaces on the

cylinder head (15) for deep gouges and nicks. Also,

inspect the cylinder head for any cracks or port thread

damage. If detected, the compressor must be replaced.

If large amounts of carbon build-up are present in the

discharge cavity such that it restricts the air fl ow through

the cylinder head, the compressor should be replaced.

2. Carefully inspect both sides of the head gasket surfaces

on the cooling plate (14) for deep gouges and nicks.

Also, inspect the cooling plate for any cracks or other

damage. If damage is found, the compressor must be

replaced.

3. Carefully inspect the valve plate assembly (13) gasket

surfaces (both sides) for deep gouges and nicks. Pay

particular attention to the gasket surface. An inlet

reed valve/gasket (5) is used between the valve plate

assembly (13) and crankcase. These gasket surfaces

must be smooth and free of all but the most minor

scratches. If excessive marring or gouging is detected,

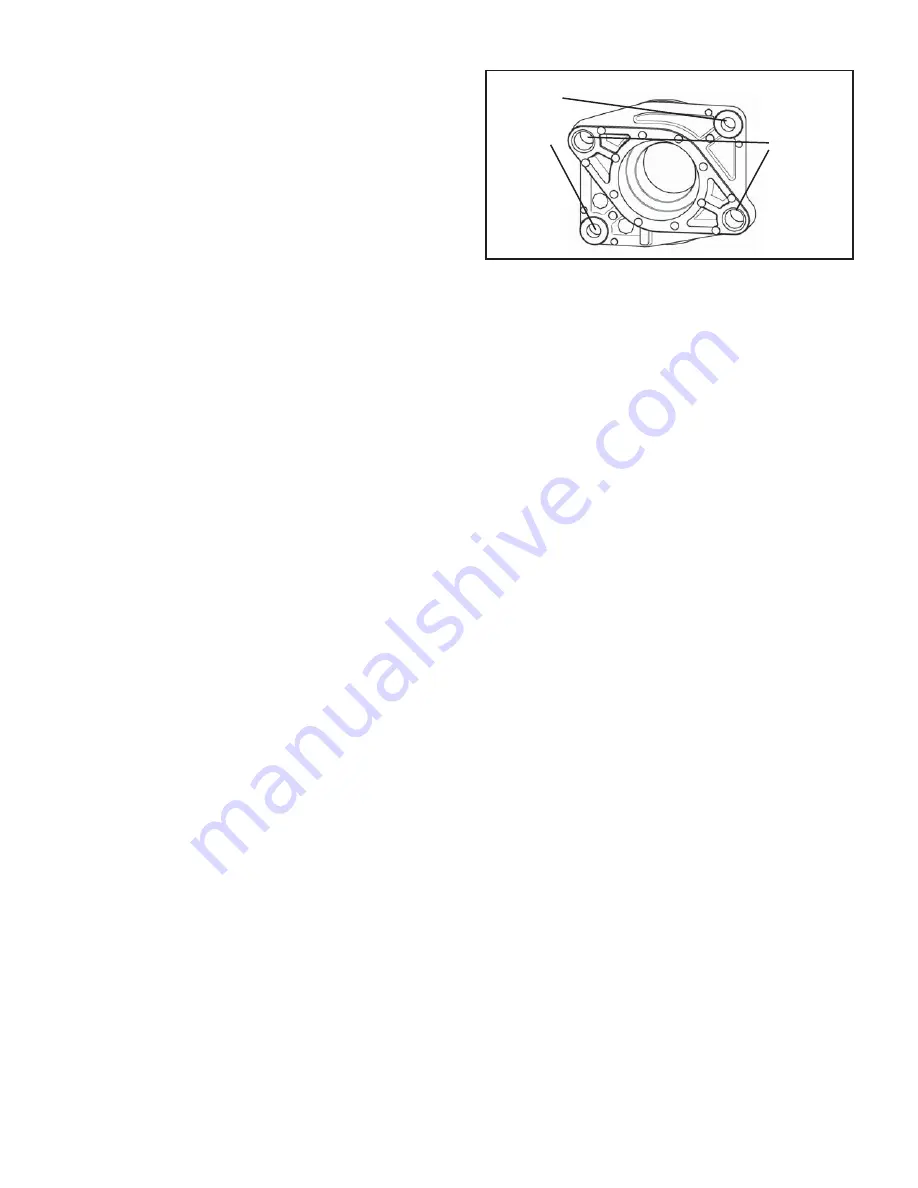

FIGURE 9 - REAR END COVER ATTACHMENT BOLTS

M10x1.5

Cap

Screws

(Larger)

M8x1.25

Cap

Screws

(Smaller)

Summary of Contents for 360CC

Page 12: ...12 Notes...