2

Tractor and trailer ABS systems operate independently of

each other. Therefore, systems will work together properly

even if they are not supplied by the same manufacturer.

For information on disassembly, installation, and service of

related axle and brake components, refer to their individual

Bendix

®

Service Manuals.

For assistance in your area call Bendix at 1-800-247-2725

or RoadRanger

®

at 1-800-826-4357.

These ABS controllers and systems were originally

marketed under the Eaton

®

Brand name. For more

information, contact Bendix or refer to your local authorized

Bendix dealer, or RoadRanger

®

.

Power Requirements for ABS

Since March 1998 the trailer wiring systems provide two

sources of power for the antilock system.

The two power sources are:

1. Full-time power (when ignition is on) must be provided

by the tractor. This full-time power source may be

shared with other trailer circuits. The SAE J560 Blue

(AUX) circuit is commonly used as the full-time power

source. In other cases, a separate ISO3731 connector

is provided.

2. Brake light power is provided as a secondary source of

power in cases where an older tractor that does not

provide full-time power is used to operate an ABS

equipped trailer.

The industry requires that the tractor provide at least 10

amps at 12 volts at the trailer end of the SAE J560 or ISO

cable on all ABS power circuits. These specifications meet

TMC RP-137 and are consistent with SAE-2247.

There are no formal requirements. However, suppliers of

Trailer ABS have agreed to provide for proper antilock brake

operation down to a minimum of 8.5 volts (at which time

the warning lamp will activate). A new TMC RP

(Recommended Practice) is being developed which

recommends that trailer manufacturers provide a 1.0 volt

safety margin over the 8.5 volt minimum.

System current requirements will not exceed 0.5 amps per

control unit and three amps per valve.

A-18

™

trailer ABS system modulators have a nominal

resistance of 5.5 ohms and require approximately two amps

to operate. The control unit is designed to power warning

lamps with a typical current of 300mA for trailer mounted

warning lamps and 100mA for cab mounted warning lamps.

Trailer Mounted ABS Warning Light

Rules for the location, color, labeling, intensity and

photometrics for external ABS warning lamps have been

established by the National Highway Transportation Safety

Administration (NHTSA). These requirements were

effective as of March 1, 1998.

Location

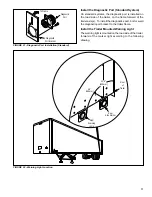

The lamp mounting location shall be near the left side rear

of the trailer, no closer than 150 mm (5.9 inches) and not

more than 600 mm (23.6 inches) from the rear red side

marker indicator lamp. (Refer to Figure 22.) On a converter

dolly, the lamp mounting location shall be on a permanent

structure of the dolly at least 375 mm (14 inches) above

the road surface.

Color and Labeling

The malfunction indicator lamp must be yellow in color and

identified with the letters “ABS” to distinguish the lamp from

other yellow side markers. The letters may be on the lens,

on the lens housing, or on the trailer itself, near the lamp.

Intensity and Photometric Requirements

The external ABS malfunction indicator lamp must conform

to SAE-J592 JUN92. Trailers shall use a combination

clearance/side marker lamps marked with a “PC” or “P2”.

These lamps offer a widely diffused beam pattern

throughout a full 180-degree left and right range.

ABS