5

PREVENTIVE MAINTENANCE

Important:

Review the warranty policy before performing

any intrusive maintenance procedures. An extended

warranty may be voided if intrusive maintenance is

performed during this period. Purge valve maintenance

is permissible during the warranty period only when using

a genuine Bendix

®

purge valve kit.

Because no two vehicles operate under identical

conditions, maintenance and maintenance intervals will

vary. Experience is a valuable guide in determining the best

maintenance interval for any one particular operation.

Every 900 operating hours, or 25,000 miles, or three

(3) months:

1. Check for moisture in the air brake system by opening

reservoir drain valves and checking for the presence

of water. If moisture is present, the desiccant cartridge

may require replacement; however, the following

conditions can also cause water accumulation and

should be considered before replacing the desiccant:

A. An outside air source has been used to charge the

system. This air did not pass through the drying

bed.

B. Air usage is exceptionally high and not normal for

a highway vehicle.

This may be due to accessory air demands or some

unusual air requirement that does not allow the

compressor to load and unload (compressing and

non-compressing cycle) in a normal fashion. Check

for high air system leakage. If the vehicle vocation

has changed, it may be necessary to upgrade the

compressor size. Refer to Bendix Specifi cation

BW-100-A / Appendix D, to determine if any changes

are necessary. Specifi cation BW-100-A is available

from the Bendix TechTeam at 1-800-247-2725 or

www.bendix.com.

C. The location of the air dryer and reservoir system

is too close to the air compressor. Refer to Bendix

Specifi cation BW-110-A / Appendix B, for discharge

line lengths.

D. In areas where more than a 30 degree range of

temperature occurs in one day, small amounts

of water can temporarily accumulate in the air

brake system due to condensation. Under these

conditions, the presence of small amounts of

moisture is normal.

For Bendix

®

AD-IS

®

PuraGuard

®

oil coalescing

air dryers only - every 3,600 operating hours, or

100,000 miles, or 12 months:

Oil removal requirements for air brake quality vary

by vehicle manufacturer. Because vehicle vocation

and maintenance can infl uence when the Bendix

®

AD-IS

®

PuraGuard

®

oil coalescing air dryer cartridge

requires replacement, each fl eet should modify their

replacement schedule based on experience. The

change out interval will be extended if the compressor

passes a low level of particles. The interval will be

reduced if excessive carbon particles are delivered to

the dryer inlet. Higher compressor build up times at

idle, as well as water or oil in downstream reservoirs

indicate an AD-IS PuraGuard oil coalescing air dryer

desiccant cartridge may need to be replaced.

Note: A small amount of oil in the system is normal and

should not be considered as a reason to replace the

desiccant cartridge. Some oil at the dryer exhaust is

also normal.

2. Visually check for physical damage, such as chaffed or

broken air and electrical lines, and broken or missing

parts.

3. Check

the

AD-IS

®

air dryer and purge reservoir bolts for

tightness. See Figure 1. Re-torque the three air dryer

bolts to 360–420 in-lbs and the four purge reservoir

bolts to 300–360 in-lbs.

4. Perform the Operation & Leakage Tests listed in this

publication.

WARNING!

This air dryer is intended to remove moisture and other

contaminants normally found in the air brake system.

Do not inject alcohol, anti-freeze, or other de-icing

substances into—or upstream of—the air dryer and

reservoir system. Alcohol is removed by the dryer,

but reduces the effectiveness of the device to dry air.

Use of these or other substances can damage the air

dryer and may void the warranty.

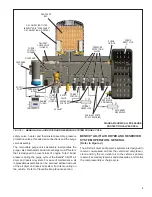

FIGURE 4 - HEATER AND THERMOSTAT CONNECTOR

HEATER & THERMOSTAT

CONNECTOR