7

psi (±6 psi) there should be an associated leveling off (or

momentary slight fall) of pressure as the third and fourth

pressure protection valves open. Then the primary and

secondary gauges should increase together until they

reach their full pressure of approximately 130 psi (±5

psi).

If the Bendix

®

AD-IS

®

air dryer and reservoir system does

not perform within the pressure ranges as described

above, recheck using gauges known to be accurate.

If the readings remain outside of the ranges outlined,

replace the AD-IS air dryer and reservoir system.

NOTE: There are no kits available for the servicing

of the pressure protection valves. Warning: Do not

attempt to adjust or service the pressure protection

valves—incorrect pressure protection valve settings

can result in automatic application of the vehicle spring

brakes without prior warning (in the event one of the

supply circuits experiences rapid pressure loss).

GENERAL

When rebuilding or replacing components of the air dryer

and reservoir, use only genuine Bendix

®

brand replacement

parts. For ease in servicing, the AD-IS air dryer and

reservoir have been designed so that maintenance kits can

be installed without removing the air dryer and reservoir

from the vehicle.

CAUTION:

Always depressurize the air

dryer and purge reservoir—and all other reservoirs on the

vehicle—to 0 psi before servicing the air dryer.

If—after completing the routine operation and leakage

tests—it has been determined that one or more components

of the air dryer requires replacement or maintenance, refer

to the Maintenance Kit listing shown in this manual or the

Bendix

®

Quick Reference Catalog for the appropriate kit(s).

The Quick Reference catalog (BW1114) can be ordered

and viewed on line at

www.bendix.com.

NOTE:

Kits are not available for the servicing of the

pressure protection valves (See Figure 5). Do not attempt

to adjust or service the pressure protection valves - these

are not service items.

TESTING THE BENDIX

®

AD-IS

®

AIR DRYER

AND RESERVOIR SYSTEM

Before placing the vehicle into service, perform the

following tests:

1. Close all reservoir drain valves.

2. Build up system pressure to governor cut-out and note

that the Bendix

®

AD-IS

®

air dryer purges (with an audible

burst of air), followed immediately by approximately 30

seconds of air fl owing out of the purge valve.

3. “Fan” the service brakes to reduce system air pressure

to governor cut-in. Note that the system once again

builds to full pressure and is followed by a purge at the

air dryer exhaust.

4. It is recommended that the total air system be tested for

leakage to assure that the AD-IS air dryer and reservoir

system will not cycle excessively.

BRAKING SYSTEM PROTECTION

The AD-IS air dryer allows the system to maintain one brake

circuit up to about 100 psi even after a pressure loss in the

other brake circuit. This allows a vehicle to be moved (in an

emergency), but with reduced braking capacity. Compare

this to a conventional system, where a loss of pressure in

one service tank leaves the vehicle with a limited number

of reduced braking capacity applications before the parking

brakes automatically apply and stay on

.

See Bendix publication BW5057 "Air Brake Handbook

."

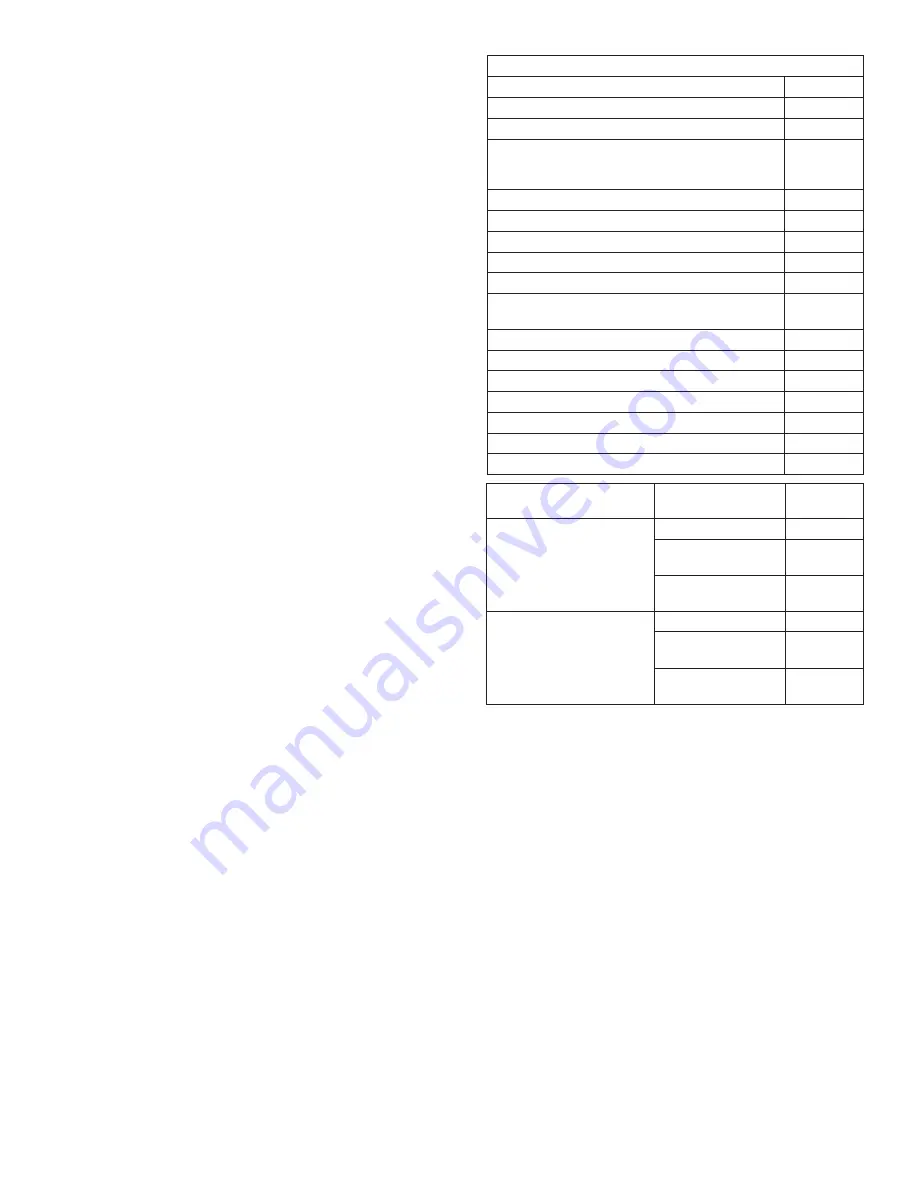

Maintenance Kits

Kit Description

Piece No.

Delivery Check Valve Replacement Kit

5004052

Desiccant Cartridge Replacement Kit (Standard)

5008414

Desiccant Cartridge Replacement Kit - Bendix

®

AD-IS

®

PuraGuard

®

air dryer (can be used to replace the standard

cartridge)

5008414PG

Drain Valve

5004961N

Governor and Check Valve Replacement Kit

5004049

Governor Gasket

5007834

Heater & Thermostat Replacement (12 volt)

109495

Heater & Thermostat Replacement (24 volt)

109496

Bendix

®

PuraGuard

®

Oil Coalescing Desiccant Cartridge

Service New Kit

K020366

Mounting Bolt Kit

5009233

Protective Boots (for pressure protection valves)

5005163

Safety Valve

800350

Splash Shield Kit (includes bracket and cover)

5006698

Splash Shield Cover

5005266N

Silencer Kit

K021189

Wiring Harness & Splice Kit

109871N

Purge Valve Assembly Type

Configuration

Service Kit

Pc. No.

Purge Valve Assembly for

climate conditions above

-40°C (-40°F)

Bendix

®

AD-IS

®

Air Dryer

K022105

AD-IS

®

EverFlow

®

Module

K031560

AD-IS

®

Discharge Line

Unloader

K031562

Arctic Purge Valve Assembly

for climate conditions of

-40°C to -50°C

(-40°F to -58°F)

AD-IS

®

Air Dryer

K031559

AD-IS

®

EverFlow

®

Module

K031561

AD-IS

®

Discharge Line

Unloader

K031563