13

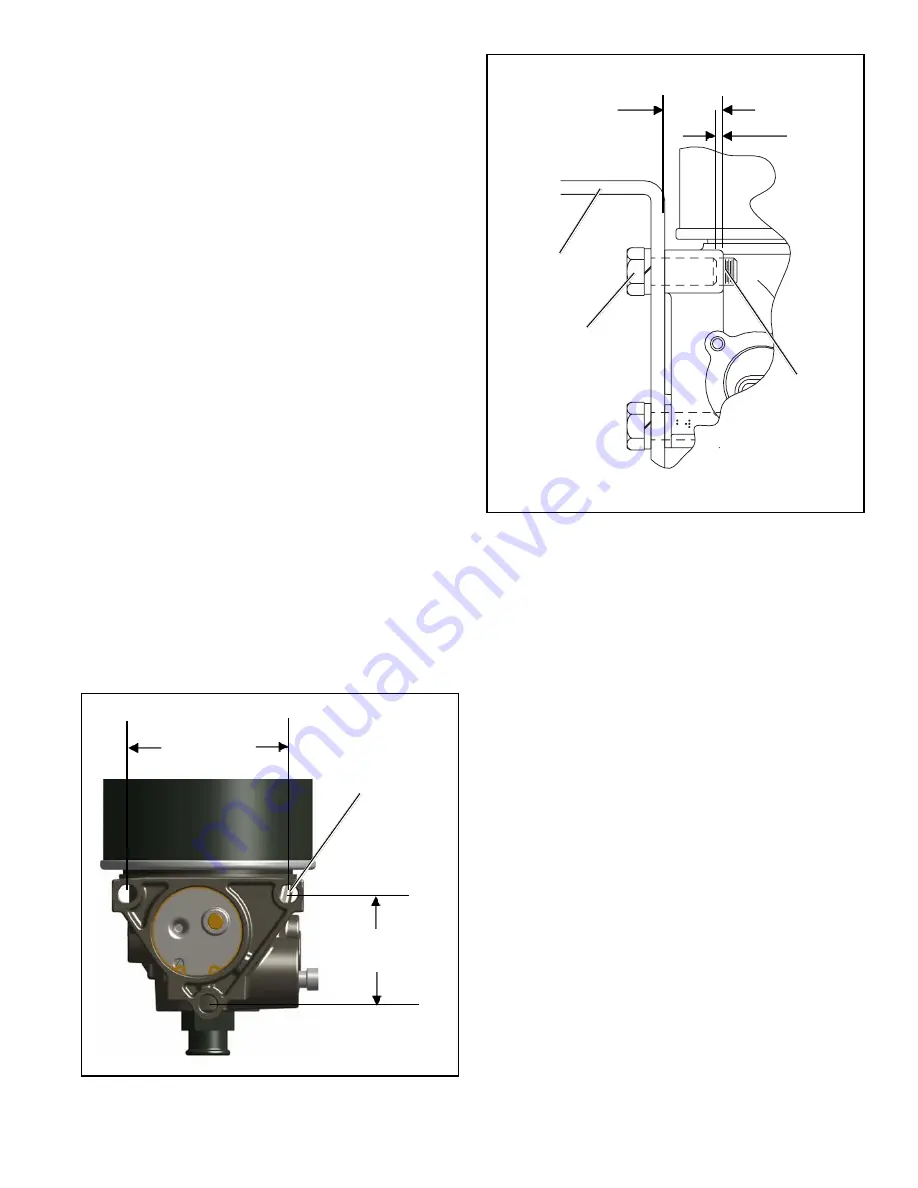

FIGURE 9 - AD-SP

™

SYSTEM PURGE AIR DRYER

MOUNTING BRACKET DIMENSIONS

3. Do not locate the AD-SP

™

air dryer near heat producing

components such as the vehicle exhaust and make

certain adequate clearance from moving components

(e.g. drive shaft, suspension, pitman arm, etc.) is

provided.

4. Locate the AD-SP

™

air dryer on vehicle so that a minimum

of 1” clearance above the cartridge is available to allow

cartridge servicing. Additionally, provide access to the

bracket bolts so the unit may be removed when

necessary.

5. When choosing the mounting location for the AD-SP

™

air dryer, note the discharge line length requirements

stated under the heading Connecting the Air Lines,

elsewhere in this manual.

Important Note: Under normal operating conditions, the

maximum inlet air temperature for the AD-SP

™

air dryer

is 150 degrees Fahrenheit.

MOUNTING THE AD-SP

™

AIR DRYER

1. Install the AD-SP

™

air dryer by referring to Figure 2 and

drilling the triangular mounting hole pattern in a mounting

plate and then mounting the plate on the vehicle or by

drilling the mounting hole pattern in the area of the vehicle

chosen for mounting. Note: Check the vehicle manual

before drilling a frame member.

2. Important: The length of the three mounting bolts used

to attach the AD-SP

™

air dryer to the mounting plate is

very important. Refer to Figure 3. The threaded end of

the 1/2" - 13 UNC bolt must be between 1/8" below to

1/4" above the surface of the AD-SP

™

air dryer mounting

bracket surface when fully installed and tightened to

50 pound feet. Damage to the dryer body will result if

the bolt warning is ignored.

Measure the thickness of all materials that the three

mounting bolts must pass through. Small adjustments can

be made using flat washers under the bolt heads. Do not

use more than 3 flat washers.

3. Mount the AD-SP

™

air dryer on the vehicle using three

1/2" bolts (grade 5 min.) of the proper length and washers.

Torque to 50 lb. ft.

INSTALLING THE SC-PR

™

VALVE

1. Refer to steps 2A and 2B under Vehicle Preparation. If

the front axle (secondary) reservoir is:

A. A single reservoir and not part of a multiple

compartment, proceed to step 2.

B. One compartment in a multiple compartment,

proceed to step 3.

2. Locate the single check valve that protects and isolates

the front axle reservoir and remove it. Remove the air

line fitting from the single check valve and install the

same fitting in the SC-PR

™

valve. Install the SC-PR

™

valve and fitting in the reservoir port that was formerly

occupied by the single check valve. Reconnect the air

line to the SC-PR

™

valve. Refer to Figure 12.

FIGURE 10 - AD-SP

™

SYSTEM PURGE AIR DRYER

MOUNTING BRACKET BOLT LENGTHS

2.835 INCHES

CENTER TO

CENTER

4.134 INCHES

CENTER TO CENTER

WIDTH (THICKNESS)

OF AD-SP

™

AIR DRYER

MOUNTING

BRACKET

MOUNTING

BOLT

1/8” BELOW

SURFACE

OF MTG.

BRACKET

VEHICLE FRAME

MEMBER

MOUNTING

BOLT

MOUNTING BOLT

1/4” ABOVE

SURFACE OF

MOUNTING

BRACKET

1/2” - 13 UNC

THREAD

(3 PLACES)