18

AD-SP

™

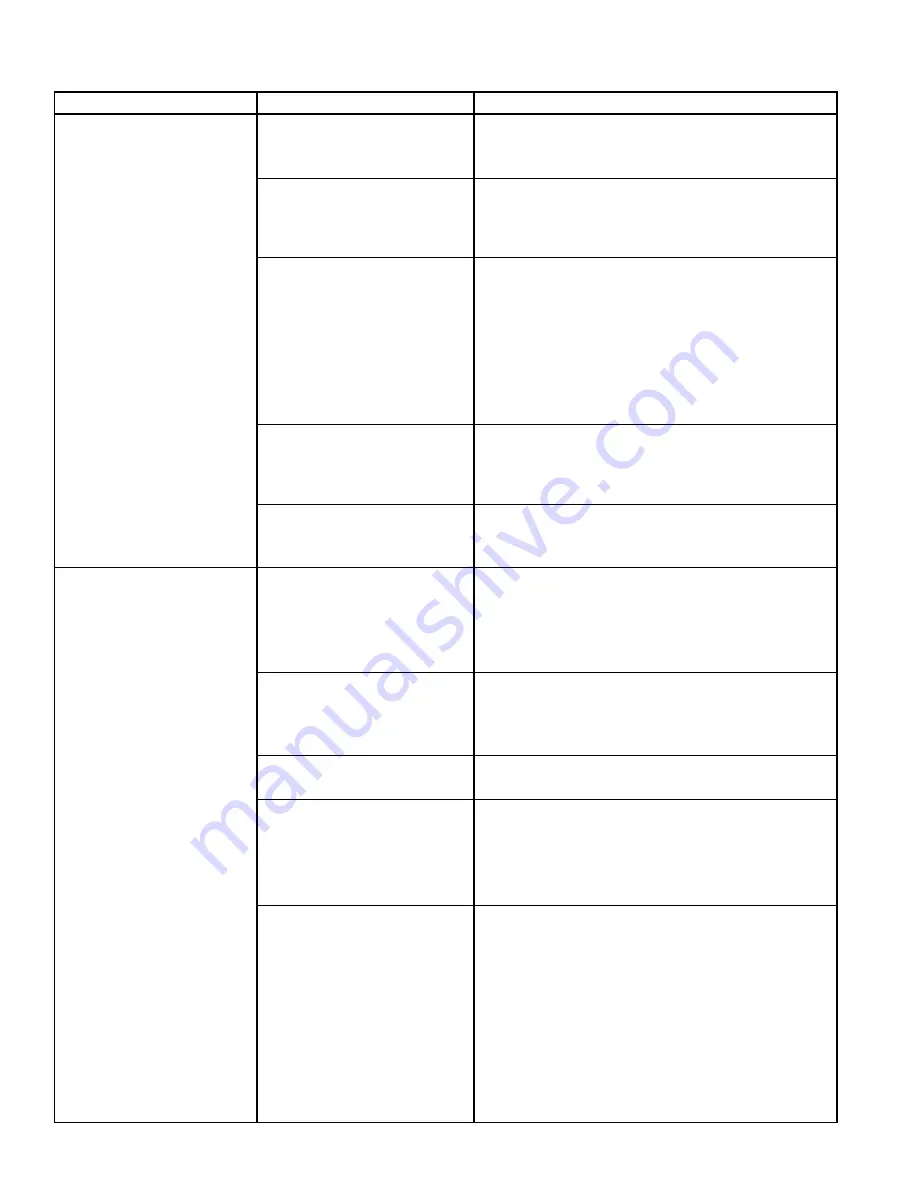

AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS

CAUSE

REMEDY

B. Locate the SC-PR

™

valve on the front axle

service (secondary) reservoir and replace.

C. Minimum setting required for AD-SP

™

air dryer

installation 100 cut in and 120 cut out. Test

operation of governor. Repair or replace as

necessary.

D. With gauge installed at RES port of governor,

pressure should not drop below "Cut In"

pressure at the onset of the compressor

"Unloaded" cycle. If pressure drops, check for

"kinks" or restrictions in line connected to RES

port. Line connected to RES port on governor

must be same diameter, or preferably larger

than, lines connected to UNL port(s) on

governor.

E. Eliminate all leakage possibilities in 1A -

Replace AD-SP

™

air dryer.

F. Refer to the "Vehicle Application

Requirements" section of this manual and

verify application.

B. Leaking (internal or

external) SC-PR

™

single

check protection valve.

C. Incorrect governor setting

or malfunctioning

governor.

D. Rapid cycling of the

governor due to air

starvation at the RES

port of the governor.

E. Leaking purge control

mechanism or delivery

check valve in AD-SP

™

air dryer.

F. High air usage - Vehicle

application.

2. Water and/or Oil in

Supply or Service

Reservoir.

A. Improper discharge line

length or improper line

material. Maximum air

dryer inlet temperature is

exceeded.

B. Air system charged from

outside air source

(outside air not passing

through air dryer).

C. Air dryer not purging

(see Symptom #5).

A. Refer to section entitled Connecting the Air Lines

as well as Appendix A, Table A columns 1 & 2

then and check line size and length.

B. If system must have outside air fill provision,

outside air should pass through air dryer. This

practice should be minimized.

C. See Symptom #5.

D. Purge (air exhaust) time

insufficient due to

excessive system

leakage (see causes for

Symptom #1).

D. Check causes and remedies for Symptom #1.

E. Excessive air usage,

duty cycle too high - Air

dryer not compatible

with vehicle air system

requirement (Improper air

dryer/vehicle

application).

E. See Appendix A, Table A, column 1, for

recommended compressor sizes. If the

compressor is “too small” for the vehicle vocation

(for example, where a vehicle’s vocation has

changed or service conditions exceed the

original vehicle or engine OE spec’s) then

upgrade the compressor. Note: The costs

incurred (e.g. installing a larger capacity

compressor, etc.) are not covered under original

compressor warranty.