2

After exiting the end cover, the air flows into the desiccant

cartridge where an oil separator, located between the outer

and inner shells of the cartridge, removes water in liquid

form as well as liquid oil and solid contaminants.

After exiting the oil separator, air enters the space between

the desiccant drying bed and the outer cartridge shell and

flows down through the column of desiccant. Flowing through

the desiccant column, air becomes progressively dryer as

water vapor adheres to the desiccant material in a process

known as “ADSORPTION.” Using the adsorption process,

the desiccant cartridge typically removes 95% of the water

vapor from the pressurized air.

Dry air exits the bottom of the desiccant cartridge through

its center opening and returns to the air dryer body

assembly. As air flows through the supply cavity it is also

conducted, via internal passages, to the non-serviceable

purge control mechanism contained in the body. The purge

control mechanism (not shown) is able to monitor supply

air pressure. The air then flows through the delivery check

valve assembly and out the delivery port to the first (supply)

reservoir of the air system. As air moves past the delivery

check valve, on its way to the delivery port, it is also

conducted to the purge control mechanism. The purge

control mechanism is able to monitor air brake system

pressure as well as supply air pressure.

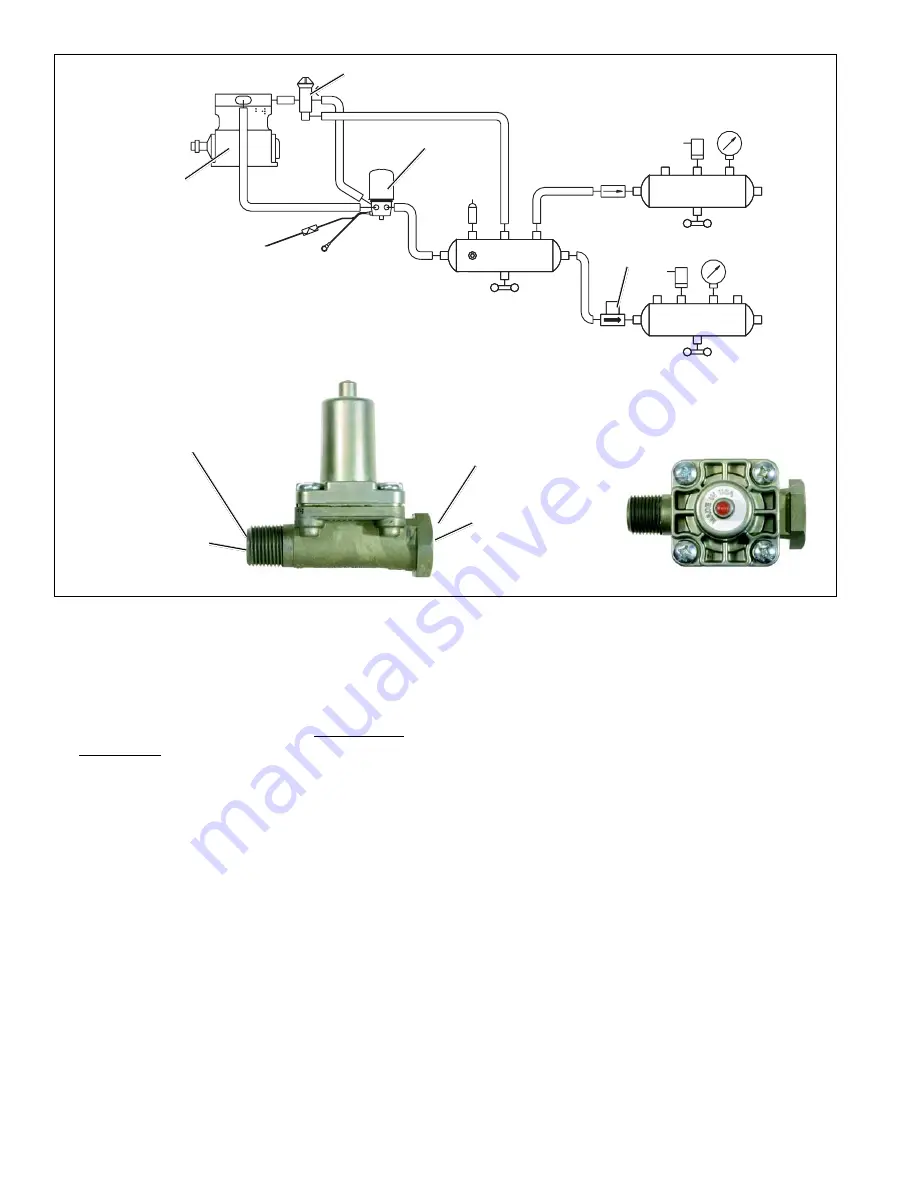

FIGURE 2 - AD-SP

™

AIR DRYER SYSTEM DRAWING WITH EXTERIOR AND TOP VIEW OF SC-PR

™

VALVE.

FRONT AXLE

AD-SP

™

AIR

DRYER

COMPRESSOR

GOVERNOR

REAR AXLE

SUPPLY

SC-PR

™

VALVE

DELIVERY PORT

(TO FRONT SERVICE

RESERVOIR)

EMBOSSED PORT

IDENTIFICATION “2 DEL”

EMBOSSED PORT

IDENTIFICATION

“1 SUP”

SUPPLY PORT

(FROM SUPPLY

RESERVOIR)

OPERATION

GENERAL

The AD-SP

™

air dryer alternates between two operational

modes or “cycles” during operation: the Charge Cycle and

the Purge Cycle. The following description of operation is

separated into these “cycles” of operation.

CHARGE CYCLE

(refer to Figure 3)

When the compressor is loaded (compressing air)

compressed air, along with oil, oil vapor, water and water

vapor flows through the compressor discharge line to the

supply port of the air dryer body.

Air entering the supply port immediately encounters the

“turbo cut-off” valve. With no air pressure in the control port,

the turbo cut-off piston moves the valve away from its seat

in the body allowing the supply air to enter the body. As air

travels through the end cover assembly, its direction of flow

changes several times, reducing the temperature, causing

contaminants to condense and drop to the bottom or sump

of the air dryer body.