22

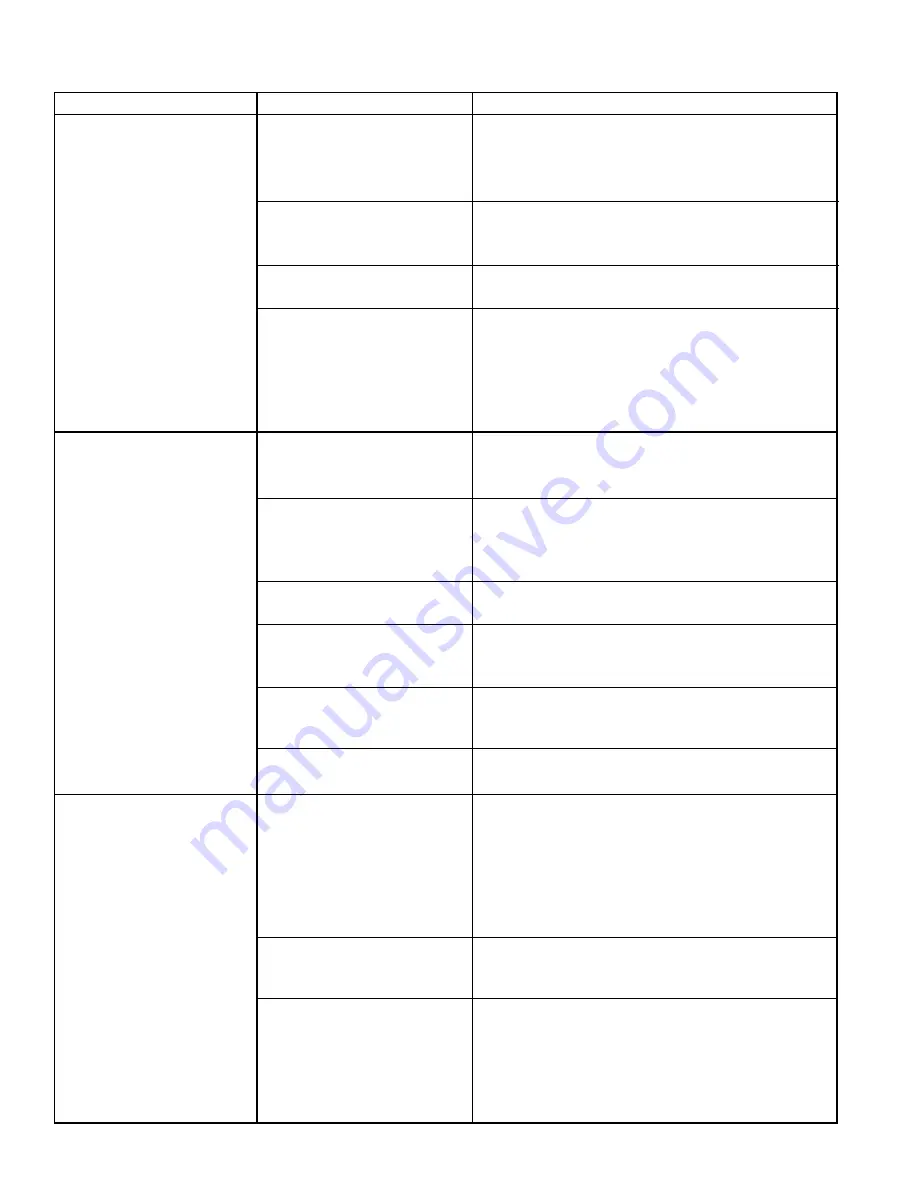

8. Air dryer does not purge

or exhaust air. Note:

this symptom often

precedes Symptom #9

if desiccant cartridge is

not replaced.

A. Air not reaching AD-SP

™

air dryer purge control

port.

B. AD-SP

™

air dryer purge

valve or piston frozen

closed.

C. Extremely high air usage

requirements on vehicle.

AD-SP

™

AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS

A. Inspect discharge line installation for water traps

that could freeze. Refer to “Connecting The Air

Lines” section in manual. Repair or replace as

necessary.

B. Test compressor unloader mechanism for

proper operation. Repair or replace as

necessary.

C. Test governor for proper operation. Repair or

replace as necessary.

D. Kinked, plugged, damaged hose tubing or fittings

in line between supply reservoir and low

pressure service reservoir

A. Check that purge control of AD-SP

™

air dryer is

connected to governor UNL (unloader) port on

governor.

B. Inspect for kinked, plugged, damaged hose

tubing or fittings. Check for undrilled or restricted

hose or tubing fittings. Repair or replace as

necessary.

C. Test governor operation. Repair or replace as

necessary.

D. Test compressor unloader mechanism for

proper operation. Repair or replace as

necessary.

E. Check operation of AD-SP

™

air dryer heater and

thermostat. Repair or replace as necessary.

F. Check operation and repair or replace as

necessary.

CAUSE

REMEDY

6. Unable to build air

system pressure. Air

not escaping from

AD-SP

™

air dryer

exhaust (not exhibiting

Symptom #4 plus this

symptom.)

A. Frozen discharge line.

B. Compressor unloader

mechanism

malfunction.

C. Governor malfunction.

D. Air flow to service brake

system restricted or

plugged. Air pressure on

one dash gauge normal

with no, or low pressure

on other gauge.

B. Air trapped in purge

control line (between

governor and AD-SP

™

air

dryer.)

C. Governor malfunction.

7. Unable to build air

system pressure.

A. AD-SP

™

air dryer purge

control line incorrectly

connected to governor.

D. Compressor unloader

mechanism

malfunction.

E. AD-SP

™

air dryer purge

valve piston frozen

open.

F. AD-SP

™

air dryer purge

valve piston stuck.

A. Test to determine air flows through purge control

line to purge control port on AD-SP

™

air dryer

when compressor unloaded. Check for undrilled

fittings. Purge control line broken, not

connected, mis-connected, frozen, damaged.

Inspect, repair or replace as necessary. Replace

desiccant cartridge.

B. Check operation of AD-SP

™

air dryer heater and

thermostat. Repair or replace as necessary.

Replace desiccant cartridge.

C. Refer to the Vehicle Application Requirements

section of this manual and verify application.