6

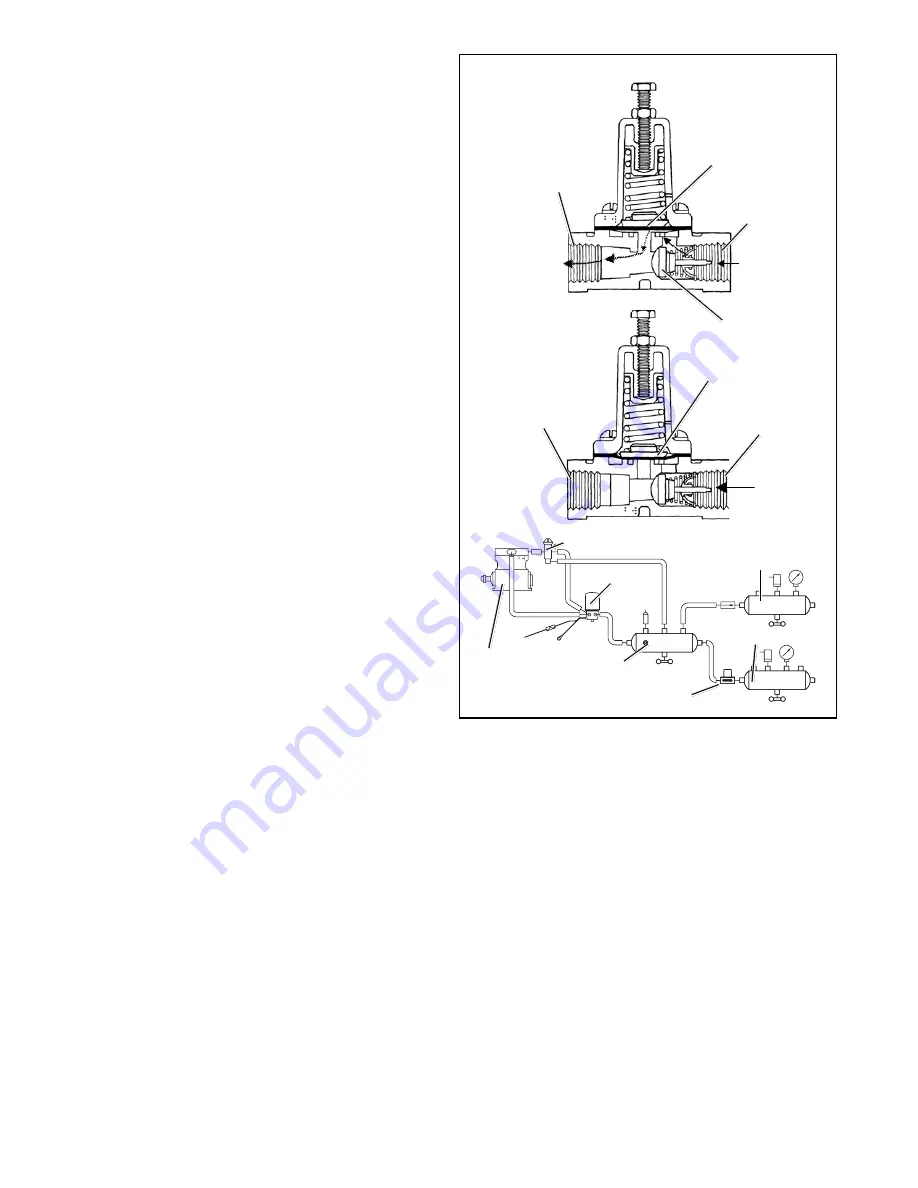

When supply pressure reaches 100 psi, the diaphragm moves

away from its seat and air entering the supply port flows through

the pressure protection valve portion, as well as the single

check valve portion, and into the front axle service reservoir.

The pressure protection valve remains open as long as

supply pressure remains above 95 psi.

PURGING

When the AD-SP

™

air dryer begins its purge cycle, air from

the supply and front axle service reservoirs flows back to

the air dryer to re-activate the desiccant. Air flowing from

the front axle service reservoir to the supply reservoir must

pass through the SC-PR

™

pressure protection valve portion

because the single check valve portion is closed to flow in

that direction.

Since an AD-SP

™

air dryer purge cycle begins at governor

cutout (120 psi minimum) and only reduces reservoir air

pressure 8 - 14 psi, the SC-PR

™

pressure protection valve

will normally remain open. If a malfunction occurs that

causes the supply reservoir to lose pressure, air from the

front axle service reservoir will flow back to the supply

reservoir until the pressure beneath the SC-PR

™

pressure

protection valve diaphragm falls to approximately 95 psi.

With 95 psi or less beneath the diaphragm, spring force

moves the diaphragm into contact with the inlet seat and

air flow to the supply reservoir ceases. The supply reservoir

will continue to lose pressure, however 95 psi will be retained

in the front axle service reservoir for braking.

Any malfunction occurring between the compressor and

SC-PR

™

valve that causes pressure to drop below 95 psi

will result in the SC-PR

™

pressure protection valve closing

and protecting the front axle service reservoir.

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended warranty

may be voided if intrusive maintenance is performed during

this period.

Because no two vehicles operate under identical conditions,

maintenance and maintenance intervals will vary.

Experience is a valuable guide in determining the best

maintenance interval for any one particular operation.

Every 900 operating hours, or 25,000 miles or three (3)

months:

1. Check for moisture in the air brake system by opening

reservoirs, drain cocks, or drain valves and checking for

presence of water. If moisture is present, the desiccant

cartridge may require replacement; however, the following

conditions can also cause water accumulation and

should be considered before replacing the desiccant:

DIAPHRAGM

SUPPLY

PORT

DELIVERY

PORT

SINGLE

CHECK

VALVE

SUPPLY

PORT

DIAPHRAGM

DELIVERY

PORT

SUPPLY

RESERVOIR

AD-SP

™

AIR

DRYER

COMPRESSOR

GOVERNOR

SC-PR

™

VALVE

REAR AXLE

RESERVOIR

FRONT AXLE RES.

FIGURE 7 - SC-PR

™

SINGLE CHECK PROTECTION VALVE

PURGE POSITION*

NORMAL PURGE

PROTECTION

FUNCTION

A. An outside air source has been used to charge the

system. This air does not pass through the drying

bed.

B. Air usage is exceptionally high and not normal for a

highway vehicle.

This may be due to accessory air demands or some

unusual air requirement that does not allow the com-

pressor to load and unload (compressing and

non-compressing cycle) in a normal fashion. Check

for high air system leakage. If the vehicle vocation

has changed it may be necessary to upgrade the

compressor size. Refer to Appendix A, Table A and

the column entitled Vehicle Vocation.

C. The air dryer has been installed in a system that

has been previously used without an air dryer. The

system will be saturated with moisture and several

weeks of operation may be required to dry it out.

*Cutaway views are functionally correct, but do not represent current form of SC-PR

™

valve.