10

9. Install the balance piston spring (5) in the unloader

piston (7), then install the small diameter of the balance

piston (4) through the center of the spring.

10. Install the unloader cover gasket (3) on the cylinder

head making certain the unloader vent passage and

both screw holes align.

11. Position the unloader cover (2) on top of the balance

piston (4) making certain the stamped logo is visible.

12. Press and hold the unloader cover (2) in place on

the cylinder head and install both unloader cover cap

screws (1). Torque the cover cap screws (1) from 62

to 71 inch pounds (7-8 Nm).

INSTALLING THE COMPRESSOR

1. If the compressor was removed for replacement, install

the drive components.

Torque the crankshaft nut to

220 - 254 foot pounds (210-290 Nm).

2. Install any supporting bracketing on the compressor in

the same position noted and marked during removal.

3. Install the gasket on the drive flange of the compressor.

Make certain oil supply or return holes in the gasket

are properly aligned with the compressor and engine.

Gasket sealants are not recommended. Secure the

compressor on the engine and tighten the mounting

bolts.

4. Install the discharge, inlet and governor adapter fittings,

if applicable, in the same position on the compressor

noted and marked during disassembly. Make certain

the threads are clean and the fittings are free of

corrosion. Replace as necessary. See the Torque

Specifications for various fitting sizes and types of

thread on page 11 of this manual.

5. Inspect all air, oil, and coolant lines and fittings before

reconnecting them to the compressor. Make certain

o-ring seals are in good or new condition. Tighten all hose

clamps.

6. Clean oil supply line. Before connecting this line to the

compressor. Run the engine briefly to be sure oil is

flowing freely through the supply line.

7. Before returning the vehicle to service, perform the

Operation and Leakage Tests specified in this manual.

Pay particular attention to all lines reconnected during

installation and check for air, oil, and coolant leaks

at compressor connections. Also check for noisy

operation.

TESTING REBUILT COMPRESSOR

In order to properly test a compressor under operating

conditions, a test rack for correct mounting, cooling,

lubricating, and driving the compressor is necessary. Such

tests are not compulsory if the unit has been carefully rebuilt

by an experienced person. A compressor efficiency or

build up test can be run which is not too difficult. An engine

Sequence Torque

(Nm)

1 . . . . . . . . . . . 13

2 . . . . . . . . . . . 13

3 . . . . . . . . . . . 20

4 . . . . . . . . . . . 20

5 . . . . . . . . . . . 20

6 . . . . . . . . . . . 20

7 . . . . . . . . . . . 20

8 . . . . . . . . . . . 20

lubricated compressor must be connected to an oil supply

line of at least 15 psi. pressure during the test and an oil

return line must be installed to keep the crankcase drained.

Connect to the compressor discharge port, a reservoir with

a volume of 1500 cubic inches, including the volume of the

connecting line. With the compressor operating at 2100

RPM., the time required to raise the reservoir(s) pressure

from 85 psi to 100 psi should not exceed 5 seconds. During

this test, the compressor should be checked for gasket

leakage and noisy operation, as well as unloader operation

and leakage. If the compressor functions as indicated

reinstall on the vehicle connecting all lines as marked in

the disassembly procedure.

BA-922

®

COMPRESSOR SPECIFICATIONS

Typical weight ................................................................. 60 lbs.

Number of cylinders ............................................................... 2

Bore Diameter ...................................... 3.622 in. (95.005 mm)

Stroke ................................................... 2.125 in. (53.970 mm)

Calculated displacement at 1250 RPM .................... 31.7 CFM

Flow Capacity @ 1800 RPM & 120 PSI ..................... 25.2 CFM

Flow Capacity @ 3000 RPM & 120 PSI ..................... 38.4 CFM

Maximum recommended RPM ................................ 3000 RPM

Minimum coolant flow maximum RPM ............... 2.0 Gals./Min.

Approximate horsepower required:

Loaded 1800 RPM at 120 PSIG ................................... 8.73 HP

Unloaded 1800 RPM .................................................... 1.96 HP

Maximum inlet air temperature ........................................ 170°F

Maximum discharge air temperature ............................... 350°F

Minimum oil pressure required ....................................... 15 PSI

Minimum oil-supply line size ...................................... 3/16" I.D.

Minimum unloader-line size ....................................... 3/16" I.D.

Minimum Governor Cutout Pressure ............................. 120 PSI

Sequence Torque

(Nm)

9 . . . . . . . . . . . 32

10 . . . . . . . . . . 32

11 . . . . . . . . . . 32

12 . . . . . . . . . . 32

13 . . . . . . . . . . 32

14 . . . . . . . . . . 32

15 . . . . . . . . . . 13

16 . . . . . . . . . . 13

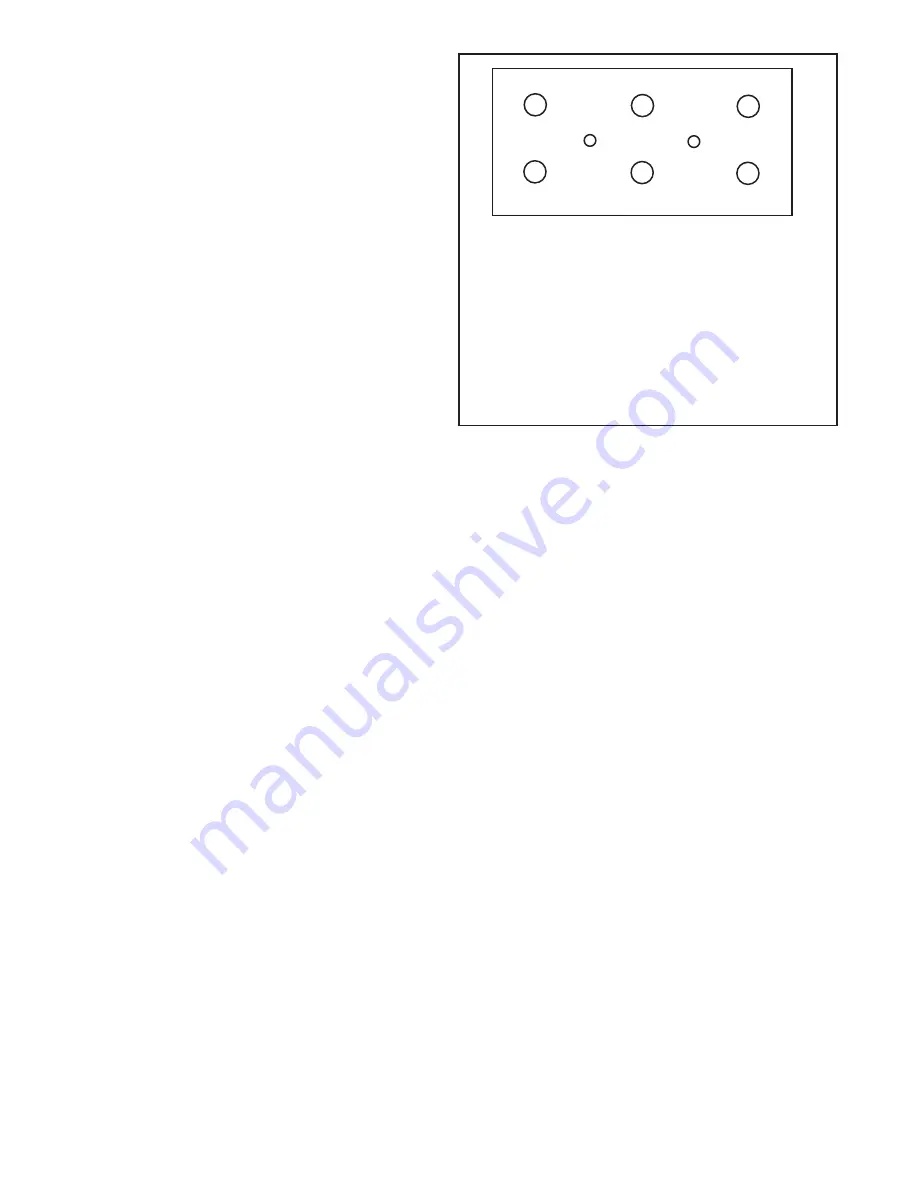

FIGURE 10 -

BA-922

®

COMPRESSOR HEAD BOLT TORQUE

SEQUENCE.

5, 11

3, 9

8, 14

6, 12

4, 10

7,13

1, 15

2, 16