2

AIR INTAKE (LOADED)

During the piston down stroke, a vacuum is created in

the cylinder bore above the piston. The vacuum causes

the inlet reed valve to flex open. Atmospheric air flows

through the open inlet valve and fills the cylinder bore

above the piston.

AIR COMPRESSION (LOADED)

When the piston reaches approximately bottom dead center

(BDC), the inlet reed valve closes. Air above the piston is

trapped by the closed inlet reed valve and is compressed

as the piston begins to move toward top dead center

(TDC). When air in the cylinder bore reaches a pressure

greater than that of the system pressure the discharge

reed valves open and air flows into the discharge line and

air brake system.

Air, during the compression stroke, flows into the hollow

center of the unloader piston through an opening in the end

of the piston. Compressed air acts on the interior surfaces

of the unloader piston and, along with the unloader piston

spring, holds the unloader piston against its seat on the

valve plate. See Figure 6.

NON-COMPRESSION OF AIR (UNLOADED)

When air pressure in the supply reservoir reaches the

cutout setting of the governor, the governor delivers

system air to the compressor unloader port. Air entering

the unloader port acts on the unloader piston causing it

to move away from its seat on the valve plate assembly.

When the unloader piston is unseated a passage is opened

between the cylinder bore, the air inlet cavity in the cylinder

head, and the other cylinder. Air compression ceases.

See Figure 7.

As the piston moves from bottom dead center (BDC) to

top dead center (TDC) air in the cylinder bore flows past

the unseated unloader piston, into the cylinder head inlet

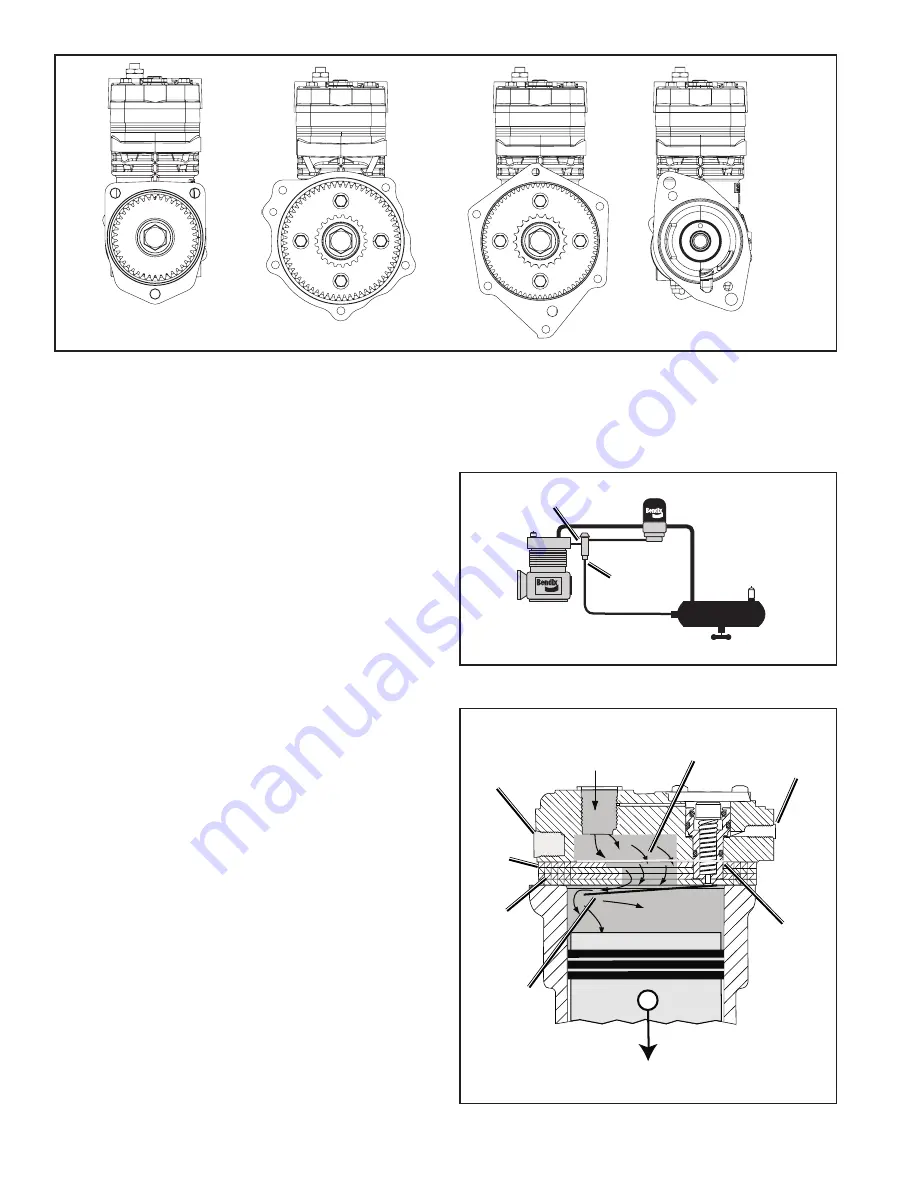

FIGURE 3 -

TYPICAL COMPRESSOR DRIVE FLANGES

cavity and into the other cylinder. A small amount of air

moves out the inlet port. On the piston down stroke (TDC

to BDC) air flows in the reverse direction, from the other

cylinder through the unloader piston to the inlet cavity, past

the unseated unloader piston and into the cylinder bore.

Detroit

Diesel

Caterpillar

FIGURE 4 -

BA-922

®

COMPRESSOR UNLOADER SYSTEM

Compressor

Supply Reservoir

Reservoir

Port

Governor

Unloader Port

Detroit

Diesel

John

Deere

Air Dryer

FIGURE 5 -

OPERATION - LOADED (INTAKE)

Piston Moving Down

Air Inlet

Port

Inlet

Valve

Open

Air

Discharge

Port

Discharge

Valve

Closed

Unloader

Piston

Down &

Seated

Valve

Plate

Unloader

Port

Cooling

Plate