2

FIGURE 2 -

WHEEL AND AXLE CONTROL SYSTEMS

bw

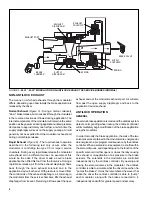

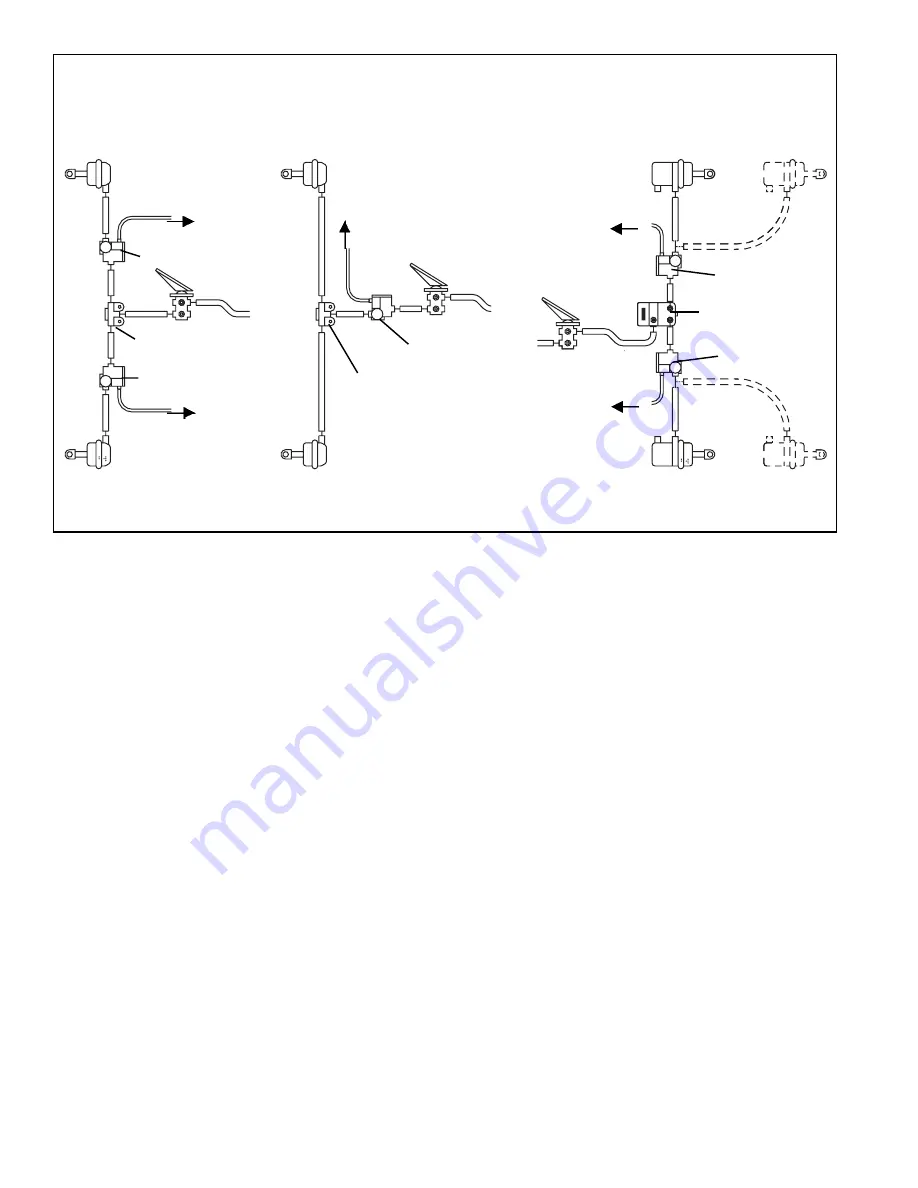

NON-ANTILOCK HOLD (FIGURE 4)

When the desired air pressure is attained in the service

brake chambers, the brake system is in the holding position.

In the holding position both solenoids in the modulator remain

de-energized and the balance of the internal components

remain in the same position as they assumed during

application.

REAR AXLE SYSTEM

FRONT AXLE SYSTEMS

AXLE CONTROL

WHEEL CONTROL

WHEEL CONTROL

SERVICE BRAKE

CHAMBER

M-21

™

OR M-22

™

MODULATOR

M-21

™

OR M-22

™

MODULATOR

QUICK RELEASE VALVE

M-21

™

OR M-22

™

MODULATOR

SERVICE BRAKE

CHAMBER

SERVICE &

SPRING BRAKE

CHAMBER

QUICK RELEASE VALVE

TO

ANTILOCK

CONTROLLER

CONTROLLER/

RELAY ASSEMBLY

M-21

™

OR M-22

™

MODULATOR

M-21

™

OR M-22

™

MODULATOR

TO

ANTILOCK

CONTROLLER

TO

ANTILOCK

CONTROLLER

TO

ANTILOCK

CONTROLLER

TO ANTILOCK

CONTROLLER

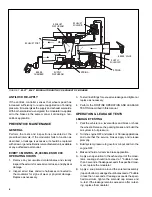

They are as follows;

Identification

Air Line Connection

1

Supply

(incoming air from foot valve or relay)

2

Delivery

(air delivery to service actuators)

3

Exhaust

(air exhaust during antilock control)

OPERATION

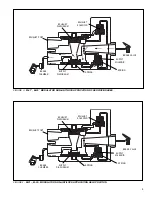

NON-ANTILOCK APPLICATION (FIGURE 3)

During normal non-antilock braking, both solenoids are de-

energized (no electrical power). Brake application air enters

the supply port of the modulator and flows to, and through,

the open exhaust solenoid then to the exhaust diaphragm.

Air pressure, along with spring force, seats the exhaust

diaphragm on the exhaust passage thus preventing the

escape of service air. Simultaneously, application air flows

to the supply diaphragm and forces it away from its seat. Air

flows past the open supply and out the modulator delivery

port to the service brake chambers.