5

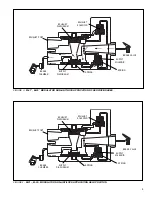

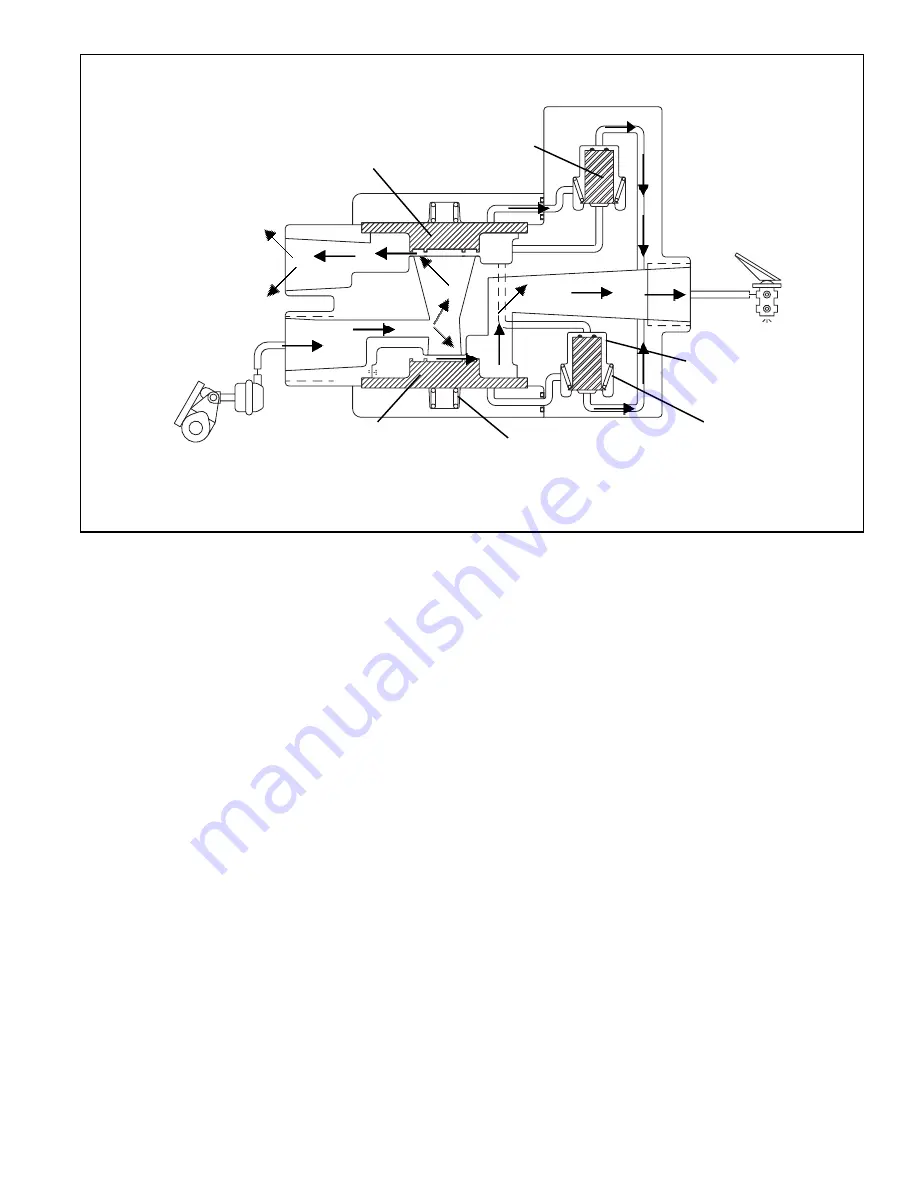

ANTILOCK EXHAUST (FIGURE 7)

When wheel lock is detected, or imminent, the antilock

controller simultaneously energizes both the supply and

exhaust solenoids in the modulator. Energizing the supply

solenoid causes its exhaust to close and inlet to open. With

the inlet of the supply solenoid open, application air is

permitted to flow to the control side of the supply diaphragm.

Air pressure acting on the supply diaphragm causes it to

close the supply and prevent further delivery of air to the

brake chamber.

Energizing the exhaust solenoid closes its inlet and opens

its exhaust. By closing the exhaust solenoid inlet, application

air is prevented from flowing to the control side of the exhaust

diaphragm. Air pressure, which was present on the control

side of the exhaust diaphragm flows out the exhaust port of

the modulator. With control air pressure removed from the

exhaust diaphragm, brake application air forces the exhaust

diaphragm to unseat which allows it to flow out the modulator

exhaust port. The modulator will remain in the antilock

exhaust mode until the antilock controller senses that wheel

speed has increased. The modulator can enter the antilock

hold or re-apply mode from the antilock exhaust mode.

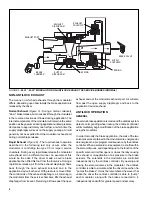

ANTILOCK HOLD

The antilock controller will place the modulator in the hold

position when it senses that the correct wheel speed (braking

force) has been attained. The antilock controller will also

place the modulator in the hold position, prior to entering

the re-apply, when it detects recovery from a locked wheel

condition. In this mode of operation the modulator supply

solenoid remains energized while the exhaust solenoid is

de-energized. De-energizing the exhaust solenoid opens its

inlet and closes its exhaust. Opening the exhaust solenoid

inlet, allows application air to flow to the control side of the

exhaust diaphragm which then seals the exhaust passage.

With the exhaust diaphragm seated, further exhaust of brake

chamber air pressure is prevented. Because the supply

solenoid remains energized the supply diaphragm remains

seated, thus preventing application air from flowing to the

delivery port and out to the brake chamber. The modulator

can enter the antilock exhaust or re-apply mode from the

antilock hold mode.

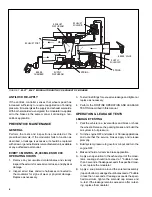

FIGURE 6 -

M-21

™

, M-22

™

MODULATOR NON-ANTILOCK EXHAUST OF SERVICE BRAKES (RAPID)

BRAKE VALVE

SPRING

SUPPLY

DIAPHRAGM

SUPPLY

SOLENOID

SPRING

EXHAUST

DIAPHRAGM

EXHAUST

SOLENOID

BRAKE

CHAMBER

EXHAUST PORT