16

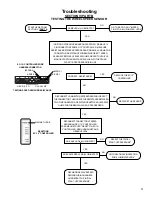

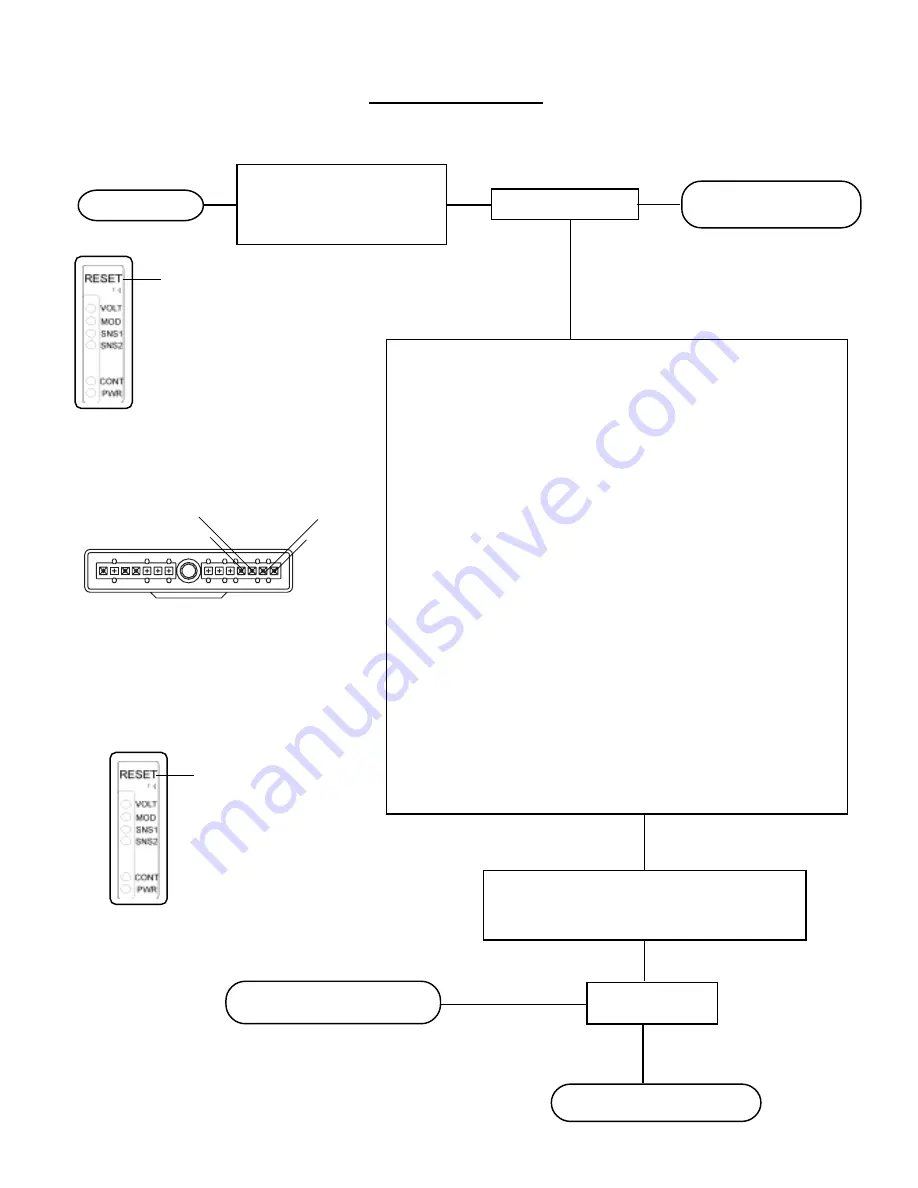

Troubleshooting

SECTION VI PART A

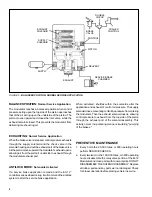

TESTING THE WHEEL SPEED SENSOR

START HERE

REPEAT THE "INITIAL START-UP

PROCEDURE

ARE ANY RED LEDs

ILLUMINATED?

GO TO SECTION III - "INSPECTION

FOR ILLUMINATED LEDs"

NO

YES

GO TO SECTION VI PART B

AND BEGIN TESTING

ANY RED LED's ON?

NO

TURN IGNITION ON & APPLY & HOLD

BRAKES ON. PASS MAGNET OVER

"RESET" ON EC-12

™

CONTROLLER.

REMOVE MAGNET AND OBSERVE

THE LEDs.

RECONNECT EC-12

™

CONTROLLER CONNECTOR, TURN

IGNITION

ON

& APPLY & HOLD BRAKES ON

.

PASS

MAGNET OVER "RESET" ON EC-12

™

CONTROLLER.

REMOVE MAGNET AND OBSERVE LEDs

YES

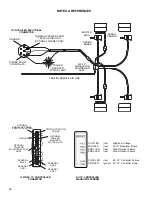

A B C D E F G

H J K L M N P

M

-SNS 2

L

-SNS 2

N

-SNS 1

P

-SNS 1

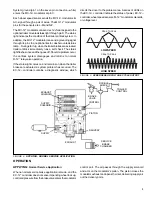

TESTING SPEED SENSOR RESISTANCE

MAGNET HERE

RESETTING

EC-12

™

CONTROLLER

MAGNET HERE

RESETTING EC-12

™

CONTROLLER

EC-12

™

CONTROLLER WIRE

HARNESS CONNECTOR

TURN IGNITION OFF, DO NOT APPLY BRAKES AND CHECK FOLLOWING:

A.

REMOVE CONNECTOR FROM EC-12

™

CONTROLLER AND MEASURE

RESISTANCE BETWEEN SPEED SENSOR M & L AND N & P. RESISTANCE

FOR BENDIX

®

WS-20

™

SPEED SENSOR SHOULD BE BETWEEN 1500-2500

OHMS. REFER TO VEHICLE MAINTENANCE MANUAL IF OTHER THAN THE

WS-20

™

SPEED SENSOR

IS IN USE. IF RESISTANCE NOT CORRECT,

DISCONNECT CONNECTOR AT

SPEED SENSOR

. INSPECT CONNECTOR,

THEN CHECK RESISTANCE BETWEEN PINS

ON SENSOR

. IF RESISTANCE IS

NOT CORRECT (BETWEEN 1500-2500 OHMS FOR THE BENDIX

®

WS-20

™

SPEED SENSOR), REPLACE SENSOR, OTHERWISE PROCEED TO STEP B.

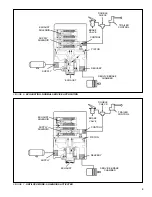

B.

CHECK “GAP” BETWEEN SPEED SENSOR AND EXCITER OR TONE RING.

(GAP FOR BENDIX

®

WS-20

™

SPEED SENSOR, SPEED SENDER IS BETWEEN 0

- .015 INCHES) IF SENSOR GAP MUST BE ADJUSTED, CHECK FOR LOOSE

OR WORN WHEEL BEARINGS

BEFORE

RE-GAPPING SENSOR. REFER TO

VEHICLE MAINTENANCE MANUAL FOR WORN BEARINGS.

C.

IF SENSOR GAP IS CORRECT CHECK WHEEL BEARING FOR FREE PLAY TO

VERIFY IT COMPLIES TO MANUFACTURER’S RECOMMENDATIONS.

D

.

MAKE CERTAIN EXCITER OR TONE RING IS IN PLACE AND INSPECT

CONDITION. CHECK FOR MISSING OR DAMAGED TEETH AND THAT IT RUNS

TRUE AND PERPENDICULAR TO SENSOR FACE.

E.

CHECK WIRING HARNESS AND CONNECTORS THAT RUN TO SENSOR.

F.

CHECK FOR DRAGGING BRAKES (OVER ADJUSTED, TRAPPED AIR IN

ACTUATOR, OUT OF ROUND DRUMS, FAULTY RETURN SPRINGS, PARKING

BRAKE SYSTEM FAULTS, ETC.) AND CORRECT AND RETEST.