2

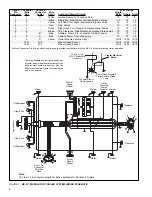

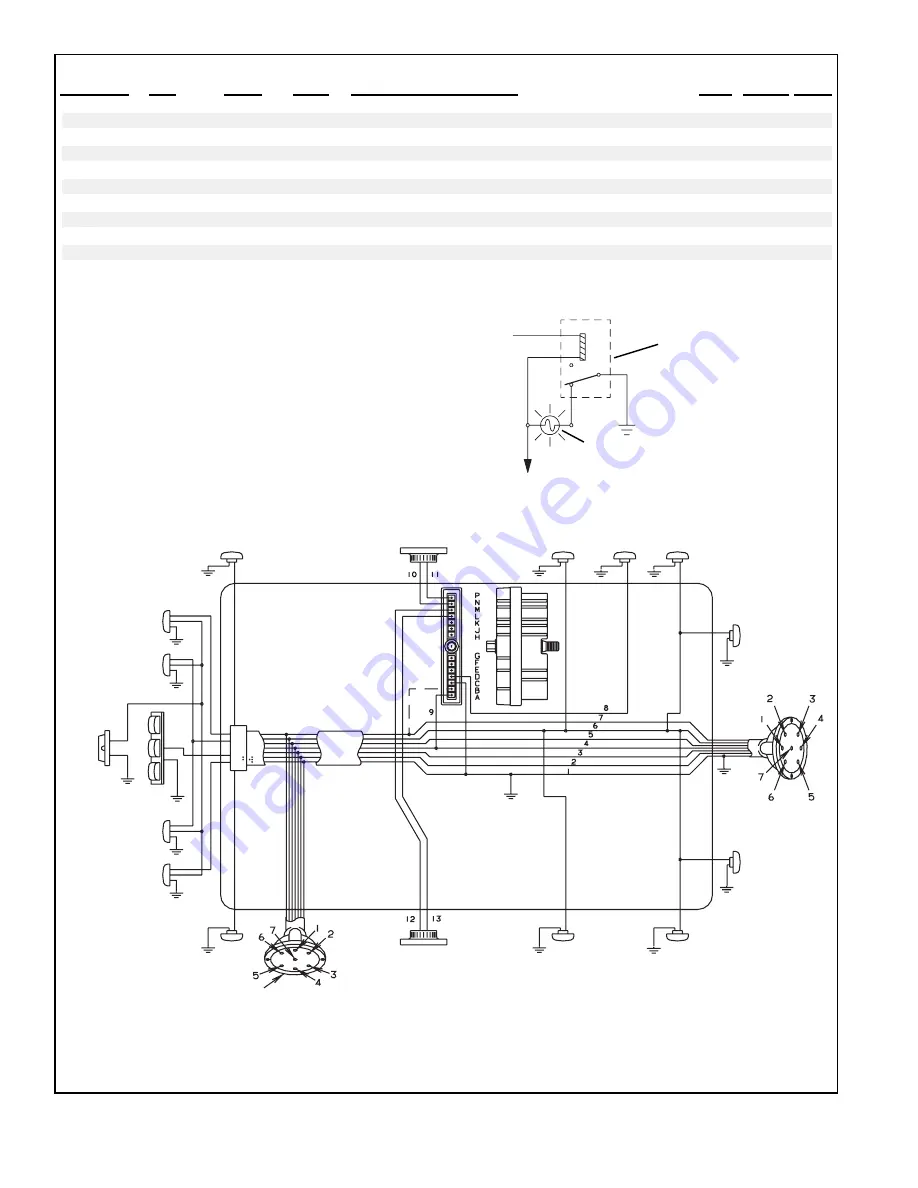

FIGURE 2 - MC-12

™

MODULATOR TRAILER SYSTEM WIRING SCHEMATIC

Seven Conductor

Antilock

Wire Gauge

Pin

(Wire

Connector

Wire

Single/

Connector

No.)

Letter

Color

Lamp and Signal Circuits

Dolly Double Triple

1

1

C

White

Ground Return To Towing Vehicle

12

10

8

2

2

-

Black

Clearance, Side Marker and Identification Lamps

12

12

12

3

3

-

Yellow

Left Hand Turn Signal and Hazard Signal Lamps

12

12

12

4

4

-

Red

Stop Lamps

10

10

10

5

5

-

Green

Right Hand Turn Signal and Hazard Signal Lamps

12

12

12

6

6

-

Brown

Tail, Clearance, Side Marker and License Plate Lamps

12

12

12

7

7

B*

Blue

Auxiliary, Dome, Etc. or constant Antilock power

12

12

12

4

9

A

Red

Antilock Power From Stop Lamp

10

10

10

-

8

D

Yellow

Trailer Mounted Status Light

14/16

14/16

14/16

-

10/11

N/P

-

Wheel Speed Sensor

16/18

16/18

16/18

-

12/13

M/L

-

Wheel Speed Sensor

16/18

16/18

16/18

* Antilock Connector Pin B is an option and is used to provide constant power to the MC-12

™

modulator during trailer operation.

Trailer

Mounted

Status

Indicator

Marker

Marker

Marker

Marker

Clearance

Clearance

Wheel

Speed

Sensor

Marker

Marker

Rear 7 Pin

Connector

Plug (See

Note)

Wheel

Speed

Sensor

CI/Directional

CI/Directional

Stop & Tail

Stop & Tail

License Plate

Note:

The rear 7 pin connector plug is for Dolly operations for Doubles & Triples

To Pin “G” on

MC-12

™

Modulator

Connector

To Power Side of

Tractor Ignition

Tractor Electrical

Relay

Tractor Dash Mounted

Trailer Antilock Status

Lamp

The relay illustrated to the right is used when

a tractor, dash mounted status lamp for the

trailer antilock system is desired. Like the

trailer mounted status lamp, this is an option

and is not required.