4

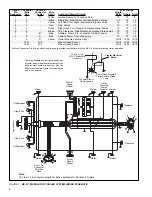

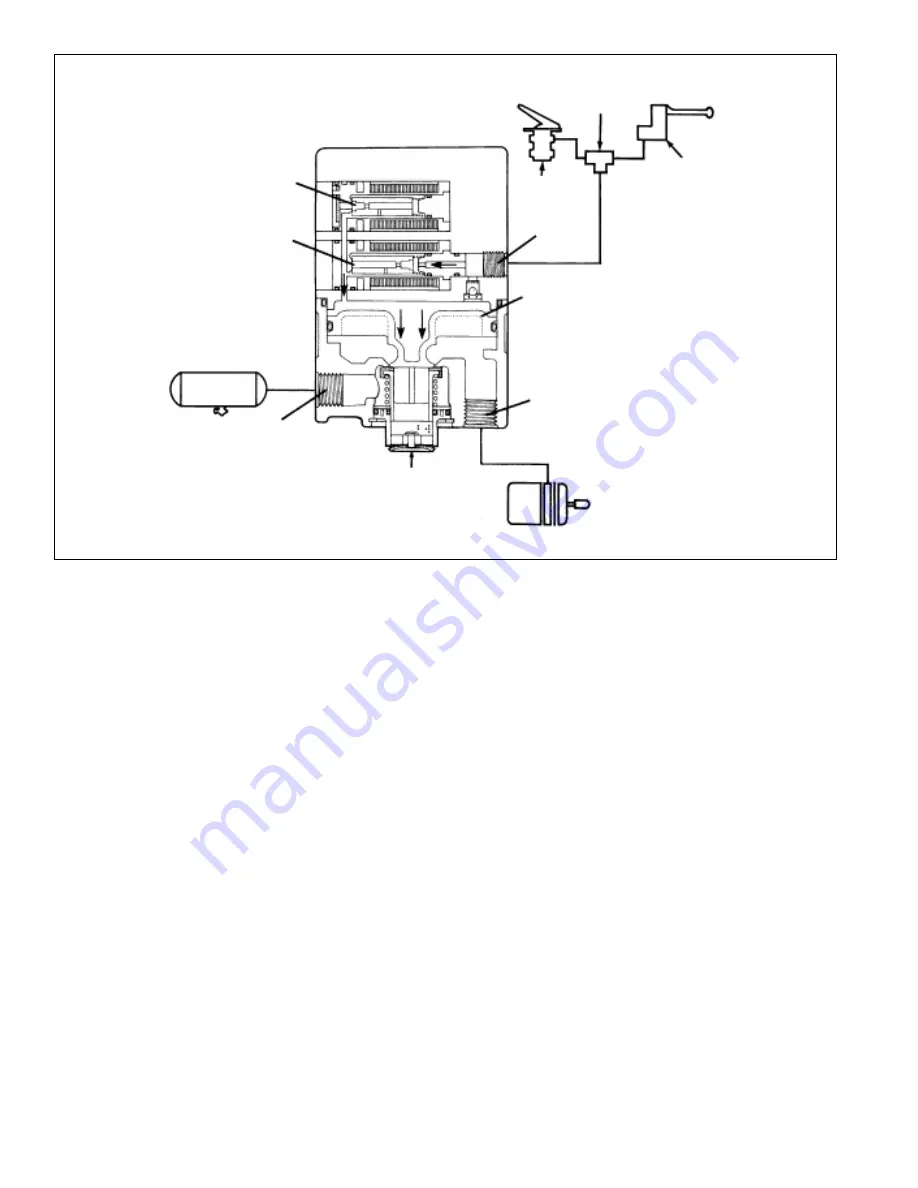

BALANCED POSITION:

Normal Service Application

The modulator reaches a balanced position when control

pressure acting upon the top side of the piston approaches

that of the air acting upon the underside of the piston. The

piston moves upward and closes the inlet valve, while the

exhaust remains closed. This prevents the modulator from

delivering or exhausting air.

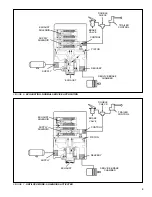

EXHAUSTING:

Normal Service Application

When the brake valve is released, control pressure exhausts

through the supply solenoid and the check valve in the

solenoid housing and out the exhaust port of the brake valve.

As the piston moves upward, the modulator's exhaust opens,

allowing air from the piston's underside to exhaust through

the modulator exhaust port.

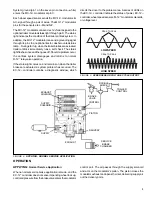

ANTILOCK MODE:

Solenoids Activated

If a service brake application is made and the EC-12

™

controller senses wheel lockup, it will command the antilock

system to alter the service brake application.

When activated, shuttles within the solenoids alter the

application and exhaust of control air pressure. The supply

solenoid closes, preventing control line pressure from entering

the modulator. Then the exhaust solenoid opens, allowing

control pressure to exhaust from the top side of the piston

through the exhaust port of the solenoid assembly. This

activity occurs in a pulsating manner, simulating "pumping

of the brakes."

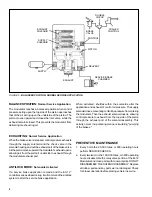

PREVENTIVE MAINTENANCE

1. Every 3 months; 25,000 miles; or 900 operating hours

perform SERVICE CHECKS.

2. Every twelve months; 100,000 miles; or 3600 operating

hours, disassemble the relay valve portion of the M-12

Modulator and clean parts with mineral spirits. DO NOT

DISASSEMBLE THE SOLENOID ASSEMBLY. Replace

all rubber parts and any parts worn or damaged. Check

for proper operation before placing vehicle in service.

FIGURE 5 - BALANCED POSITION: NORMAL SERVICE APPLICATION

TRAILER

CONTROL

DOUBLE

CHECK

BRAKE

VALVE

CONTROL

PISTON

DELIVERY

EXHAUST

SUPPLY

EXHAUST

SOLENOID

SUPPLY

SOLENOID

SERVICE BRAKE

CHAMBER