7

REMOVAL OF THE MC-12

™

MODULATOR

ASSEMBLY

1. Remove and identify all air lines connected to the unit.

2. Disconnect the 14 pin connector from the unit by

loosening its screw and pulling the connector away from

its socket.

3. Remove and save the mounting hardware connecting

the MC-12

™

modulator to the vehicle.

4. Prior to disassembly, remove as much contamination

as possible from the exterior of the assembly. Be sure

to keep the contamination away from the open ports.

INSTALLATION OF THE MC-12

™

MODULATOR ASSEMBLY

1. Replace the MC-12

™

modulator assembly on the vehicle

using the hardware saved during removal. Connect the

air lines to the proper ports, as identified during removal.

Connect the 14 pin connector into the controller and

tighten the screw.

DISASSEMBLY

The following disassembly and assembly procedure is

presented for reference purposes and presupposes that a

major rebuild of the antilock valve is being undertaken. Several

replacement parts and maintenance kits are available which

do not require full disassembly. The instructions provided

with these parts and kits should be followed in lieu of the

instructions presented here.

CAUTION

: The MC-12

™

modulator may be lightly clamped

in a bench vise during disassembly. However, over clamping

will result in damage, leakage, and/or malfunction. If a vise

is to be used, position the MC-12

™

modulator so the jaws

bear on the flat area of the supply port and its opposing side

of the body.

1. Remove the EC-12

™

controller (1) from the M-12

™

modulator by removing the controller's four mounting

bolts.

2. Lift the controller off the M-12

™

modulator and detach

the wire harness from the base of the controller by

depressing the lock tab on the side of the connector

and pulling the connector from its socket in the controller.

Remove the gasket (7) from the EC-12

™

controller body.

NOTE: If replacement of the controller only is required,

proceed to Step 8 of assembly.

3. Remove sealing ring (4) from the protrusion on the bottom

of the solenoid assembly.

4. Using a pair of snap ring pliers, remove retaining ring

(14). Remove the exhaust assembly (13). Remove

o-ring (12) and o-ring (11) from the l.D. and O.D.,

respectively, of the exhaust assembly.

5. Remove spring (10). Remove the inlet/exhaust assembly

(8). Remove the spring seat (9) from the inlet/exhaust

assembly.

6. Using your thumb, press the piston stem and push the

piston (6) out the opposite end of the body. Remove

o-ring (5) from the piston.

7. Discard all items that have replacement parts in the

maintenance kit.

CLEANING & INSPECTION

1. Using mineral spirits or an equivalent solvent, clean and

thoroughly dry all parts to be reused. Do not allow mineral

spirits to come into contact with the ECU connector or

solenoids.

2. Inspect the interior and exterior of all parts that will be

reused for severe corrosion, pitting and cracks. Superficial

corrosion and/or pitting on the exterior portion of the body

is acceptable.

3. Inspect the bores for deep scuffing or gouges.

4. Inspect the pipe threads in the body. Make certain they

are clean and free of thread sealant.

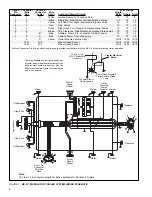

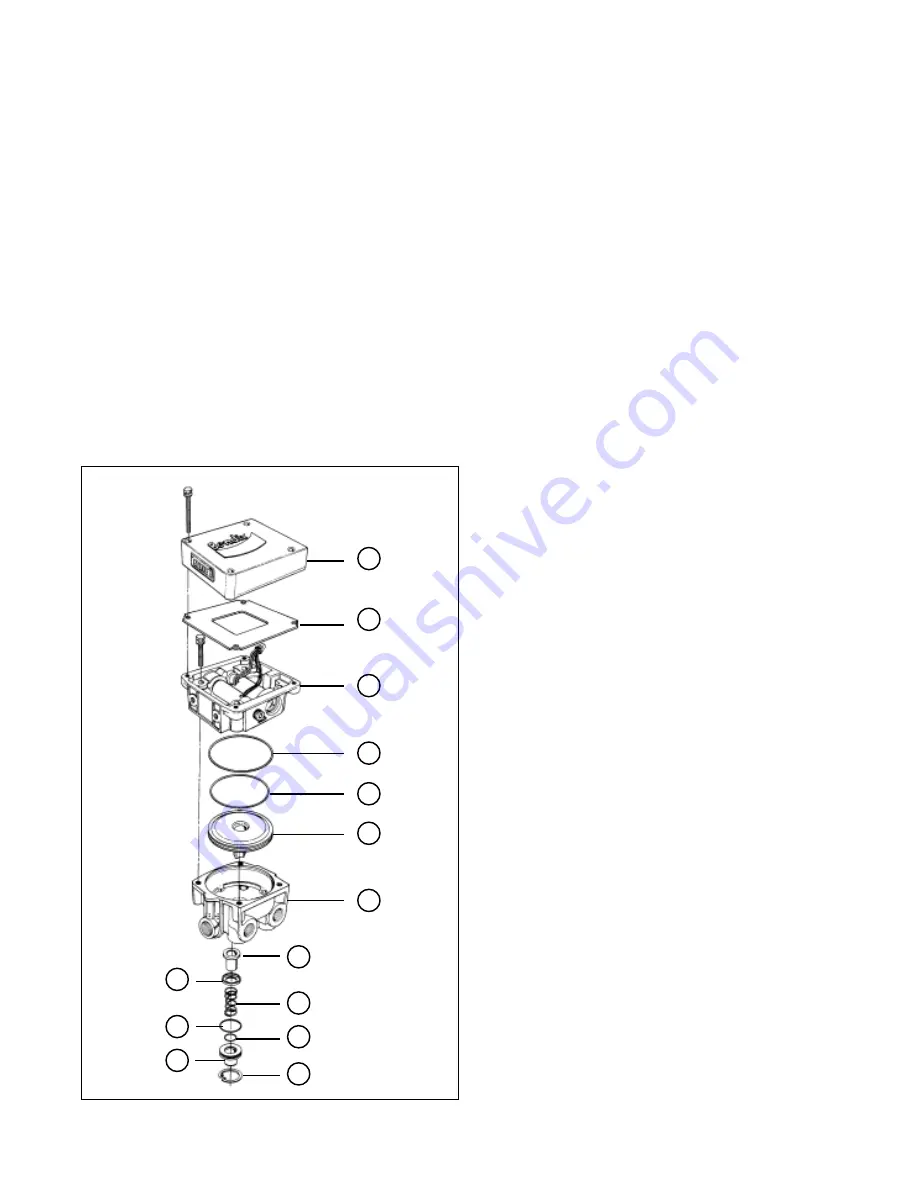

FIGURE 9 - EXPLODED VIEW

1

7

2

4

5

6

3

8

9

10

11

12

13

14