14

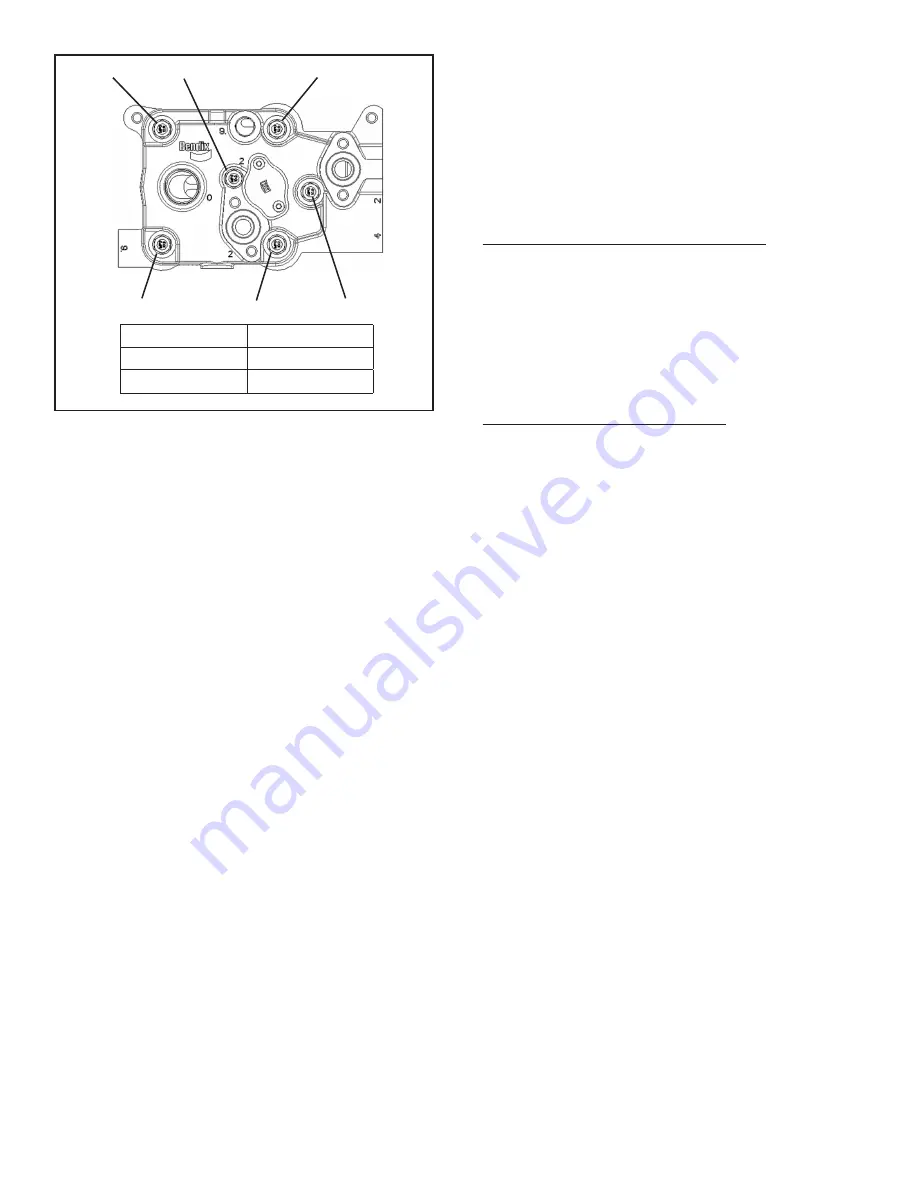

FIGURE 11 -

COMPRESSOR HEAD BOLT TORQUE

SEQUENCE

PART TWO: UNLOADER INSTALLATION

7. Apply a coating of the lubricant — provided in the

unloader kit — into the two unloader bores. Apply

additional lubricant to the three o-ring grooves on the

unloader piston (10). Install the three o-rings (7, 9, 11)

into the appropriate o-ring grooves on the unloader

piston. Note that the o-ring (7) installs inside the top

of the unloader piston. Apply another coating of the

lubricant onto the exposed o-ring surfaces and onto

the large diameter of the balance piston (6). Install

the unloader piston with the pre-installed o-rings into

the cylinder head unloader bore making certain not to

damage them in the process.

8. Install the balance piston spring (8) in the unloader

piston (10).

9. Apply a coating of lubricant to the largest diameter of

the balance piston (6). Install the small diameter end

of the balance piston through the center of the balance

piston spring (8).

10. Install the unloader cover gasket (5) on the cylinder

head (13) making certain both screw holes align.

11. Position the unloader cover (4) on top of the balance

piston (6) making certain the stamped logo on the

unloader cover (4) is visible.

12. Press and hold the unloader cover in place on the

cylinder head. Install both unloader cover cap screws

(2). Torque the unloader cover cap screws (2) to 62–71

in-lbs (7–8 N•m).

PART THREE: INLET & TOP COOLANT FITTING

INSTALLATION

If the inlet fitting (35) and/or the top coolant fitting (36)

where previously removed, they should now be installed;

otherwise skip step 13.

13. There are two options for the top coolant fitting (36).

Identify the fitting you have from the two options shown

in Figure 12a and follow the steps for installation.

Option 1: M16 x 1.5–6g (ISO 9974) fitting. Back off

lock nut as far as possible. Screw fitting into port until

the leading surface of the lock nut contacts the face of

the port. Light wrenching may be necessary. To align

the tube end to the position as defined in Figure 12,

unscrew the fitting by the required amount, but not more

than one full turn. Using two wrenches, hold fitting in

desired position and tighten locknut to 319–354 in-lbs

(36–39.5 N•m).

Option 2: M16 (tapered thread) fitting.

Note: It may be

necessary to apply Teflon tape to the threads of the

fitting to aid sealing of the threads

. Install the fitting into

the coolant port to “finger tight”. Then install 2 additional

turns plus turn to position.

Next, install the inlet fitting (35) into the inlet port of the

compressor. Back off the lock nut as far as possible.

Make sure the back-up washer is not loose and is

pushed up as far as possible. Screw fitting into port

until the back-up washer contacts the face of the port.

Light wrenching may be necessary. To align the tube

end to the position as defined in Figure 12, unscrew

the fitting by the required amount, but not more than

one full turn. Using two wrenches, hold fitting in desired

position and tighten locknut to 575–633 in-lbs (65–72

N•m).

PART FOUR: DISCHARGE JUMPER ASSEMBLY

INSTALLATION (REFER TO FIGURE 12)

14. Apply a coating of lubricant to the two discharge jumper

o-rings (40) and install the o-rings into the two o-ring

grooves on the cylinder head (13).

15. If the safety valve (12) was previously removed from

the discharge jumper (41), screw the safety valve into

the side port of the discharge jumper (37) and torque

to 200–249 in-lbs (22.5–28 N•m).

16. Position the discharge jumper (37) over the cylinder

head (13) such that it lines up with the four attachment

bolt holes.

Refer to Figure 13

to ensure proper

orientation on the cylinder head (13) Note: There is only

one way the discharge jumper can be installed on the

cylinder head.

17. Install the discharge jumper washer (39) and cap screw

(38) in each of the four holes on the discharge jumper

(37). Hand tighten the four cap screws and torque in a

cross pattern to 115–133 in-lbs (13–15 N•m).

2, 8

1, 7

5, 11

3, 9

6, 12

4, 10

Sequence

Torque (Nm)

1 through 6

20

7 through 12

31-34