20

A-2

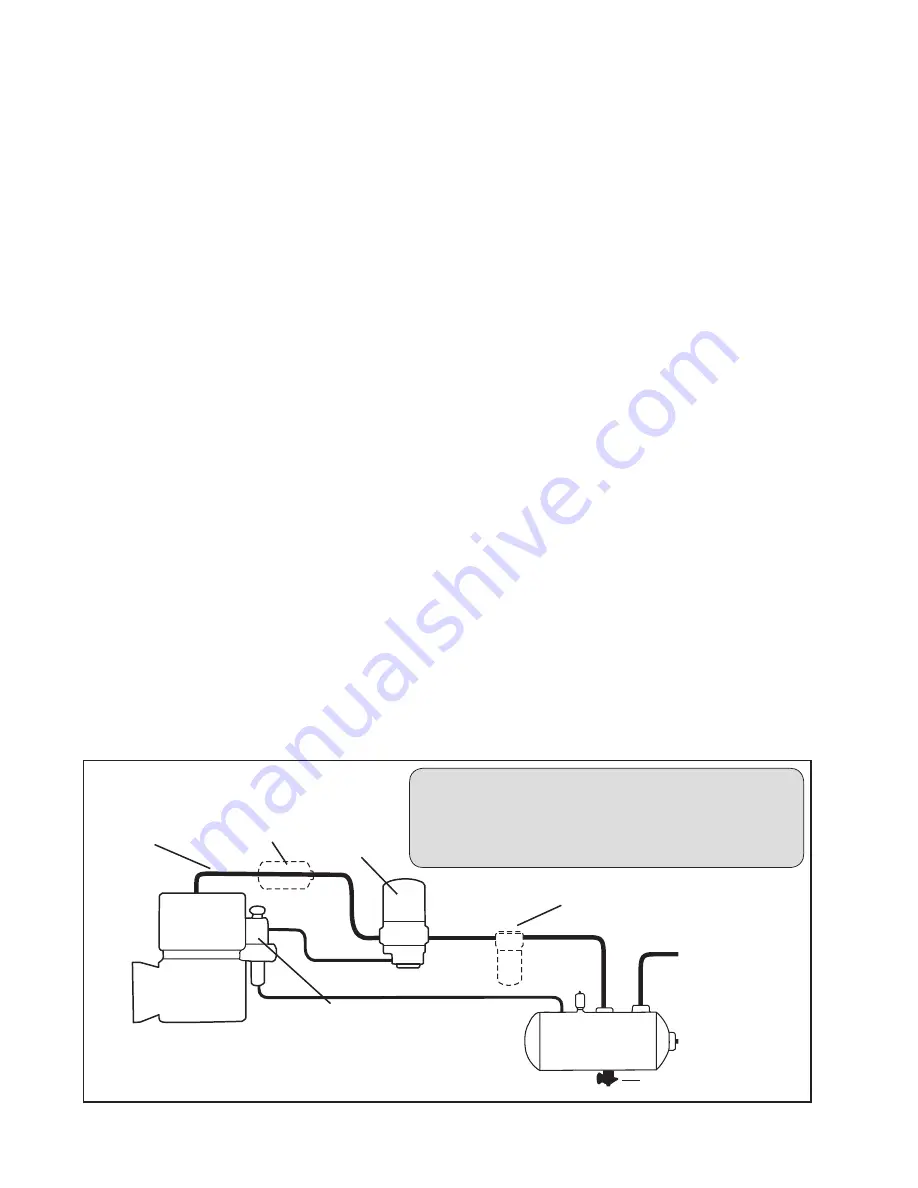

Air Dryer

Reservoir Drain

Service Reservoir

(Supply Reservoir)

Compressor

Governor

(Governor plus Synchro valve

for the Bendix

®

DuraFlo

™

596

Compressor)

Discharge

Line

Optional “Ping” Tank

Optional Bendix

®

PuraGuard

®

System Filter or PuraGuard

QC

™

Oil Coalescing Filter

The Air Brake Charging System

supplies the

compressed air for the braking system as well as other air

accessories for the vehicle. The system usually consists

of an air compressor, governor, discharge line, air dryer,

and service reservoir.

Introduction to the Air Brake Charging System

Powered by the vehicle engine, the

air compressor

builds the air pressure for the air brake system. The air

compressor is typically cooled by the engine coolant system

and lubricated by the engine oil supply.

The compressor's unloader mechanism and

governor

(along with a synchro valve for the Bendix

®

DuraFlo

596

™

air compressor) control the brake system air pressure

between a preset maximum and minimum pressure level

by monitoring the pressure in the service (or “supply”)

reservoir. When the air pressure becomes greater than that

of the preset “cut-out”, the governor controls the unloader

mechanism of the compressor to stop the compressor from

building air and also causes the air dryer to purge. As the

service reservoir air pressure drops to the “cut-in” setting

of the governor, the governor returns the compressor back

to building air and the air dryer to air drying mode.

As the atmospheric air is compressed, all the water vapor

originally in the air is carried along into the air system, as

well as a small amount of the lubricating oil as vapor.

The

duty cycle

is the ratio of time the compressor spends

building air to the total engine running time. Air compressors

are designed to build air (run “loaded”) up to 25% of the

time. Higher duty cycles cause conditions that affect air

brake charging system performance which may require

additional maintenance. Factors that add to the duty cycle

are: air suspension, additional air accessories, use of an

undersized compressor, frequent stops, excessive leakage

from fittings, connections, lines, chambers or valves, etc.

The

discharge line

allows the air, water-vapor and

oil-vapor mixture to cool between the compressor and air

dryer. The typical size of a vehicle's discharge line, (see

column 2 of Table A on page A-3) assumes a compressor

with a normal (less than 25%) duty cycle, operating in

a temperate climate. See Bendix and/or other air dryer

manufacturer guidelines as needed.

When the

temperature

of the compressed air that enters

the air dryer is within the normal range, the air dryer can

remove most of the charging system oil. If the temperature

of the compressed air is above the normal range, oil as

oil-vapor is able to pass through the air dryer and into the

air system. Larger diameter discharge lines and/or longer

discharge line lengths can help reduce the temperature.

The discharge line must maintain a

constant slope

down

from the compressor to the air dryer inlet fitting to avoid low

points where ice may form and block the flow. If, instead,

ice blockages occur at the air dryer inlet, insulation may

be added here, or if the inlet fitting is a typical 90° fitting,

it may be changed to a straight or 45° fitting. For more

information on how to help prevent discharge line freeze-

ups, see Bendix Bulletins TCH-008-021 and TCH-008-022

(see pages A-19-21). Shorter discharge line lengths or

insulation may be required in cold climates.

The

air dryer

contains a filter that collects oil droplets, and

a desiccant bed that removes almost all of the remaining

water vapor. The compressed air is then passed to the air

brake service (supply) reservoir. The oil droplets and the

water collected are automatically purged when the governor

reaches its “cut-out” setting.

For vehicles with accessories that are sensitive to small

amounts of oil, we recommended installation of a Bendix

®

PuraGuard

®

system filter, designed to minimize the amount

of oil present.