39

A-20

Bulletin No.: TCH-008-021

Effective Date: 3/5/2010

Page: 2 of

2

System Leakage

Check the air brake system for excessive air leakage using the Bendix “Dual System Air Brake Test and Check

List” (BW1396). Excessive system leakage causes the compressor to “pump” more air and also reduce the life

of the air dryer desiccant cartridge.

Reservoir Draining (System without an Air Dryer)

Routine reservoir draining is the most basic step in reducing the possibility of freeze-up. All reservoirs in a

brake system can accumulate water and other contamination and must be drained! The best practice is to

drain all reservoirs daily if the air brake system does not include an air dryer. When draining reservoirs; turn

the ENGINE OFF and drain ALL AIR from the reservoir, better still, open the drain cocks on all reservoirs and

leave them open over night to ensure all contamination is drained (reference Service Data Sheet SD-04-400 for

Bendix Reservoirs). If automatic drain valves are installed, check their operation before the weather turns cold

(reference Service Data Sheet SD-03-2501 for Bendix

®

DV-2

™

Automatic Drain Valves). It should be noted that,

while the need for daily reservoir draining is eliminated through the use of an automatic drain valve, periodic

manual draining is still required.

Reservoir Draining (System with an Air Dryer)

Daily reservoir draining should not be performed on systems with an air dryer. This practice will cause the dryer

to do excessive work (e.g. build pressure from 0-130 psi instead of the normal 110-130 psi).

Alcohol Evaporator or Injector Systems

Bendix Commercial Vehicle Systems LLC discourages the use of alcohol in the air brake system as a means

of preventing system freeze-up in cold temperatures. Studies indicate that using alcohol and alcohol based

products sold for this purpose removes the lubrication from the components of the air braking system. In

addition, the materials used for the internal seals of the air system components may be adversely impacted

by the residue that some anti-freeze additives leave behind. Both are detrimental to air system component life

expectancy, causing premature wear. Because of this, Bendix

®

air system components warranty will be void if

analysis shows that alcohol was added to the air brake system.

Alcohol is not an acceptable substitute for having adequate air drying capacity. If the air dryer is maintained in

accordance with the manufacturer’s recommended practices and moisture is found to be present in the system

reservoirs, more drying capacity is required. Bendix has several viable options including extended purge air

dryers, extended purge tandem dryers in parallel with common control, and air dryers arranged to provide

continuous flow as with the Bendix

®

EverFlow

®

continuous flow air dryer module. To address concerns with

contaminants in trailer air brake systems, the Bendix

®

Cyclone DuraDrain

®

water separator and the Bendix

®

System-Guard

®

trailer air dryer are available. Refer to Bendix Technical Bulletin TCH-008-042 “Alcohol in the

Air Brake System” for additional information.

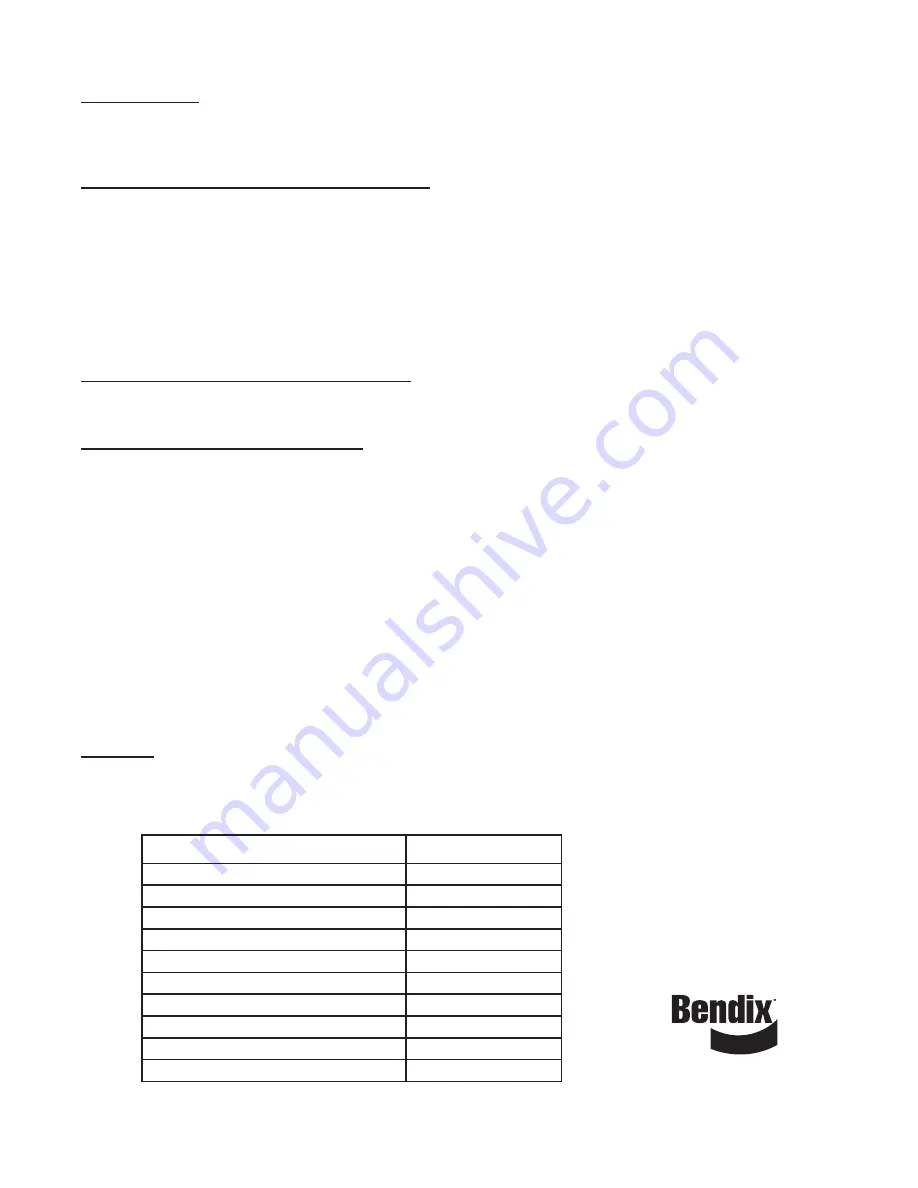

Air Dryers

Make certain air brake system leakage is within the limits stated in BW1396. Check the operation and function

of the air dryer using the appropriate Service Data Sheet for the air dryer.

Air Dryer

Service Data Sheet

AD-2

®

air dryer

SD-08-2403

AD-4

™

air dryer

SD-08-2407

AD-9

®

air dryer

SD-08-2412

AD-IP

®

air dryer

SD-08-2414

AD-IS

®

air dryer

SD-08-2418

AD-IS

®

EverFlow

®

air dryer

SD-08-2417

AD-SP

®

air dryer

SD-08-2415

Cyclone DuraDrain

®

water separator

SD-08-2402

PuraGuard

®

QC system filter

SD-08-187B

Trailer System-Guard

®

air dryer

SD-08-2416

Bendix literature is available

to order or download on

www.Bendix.com