5

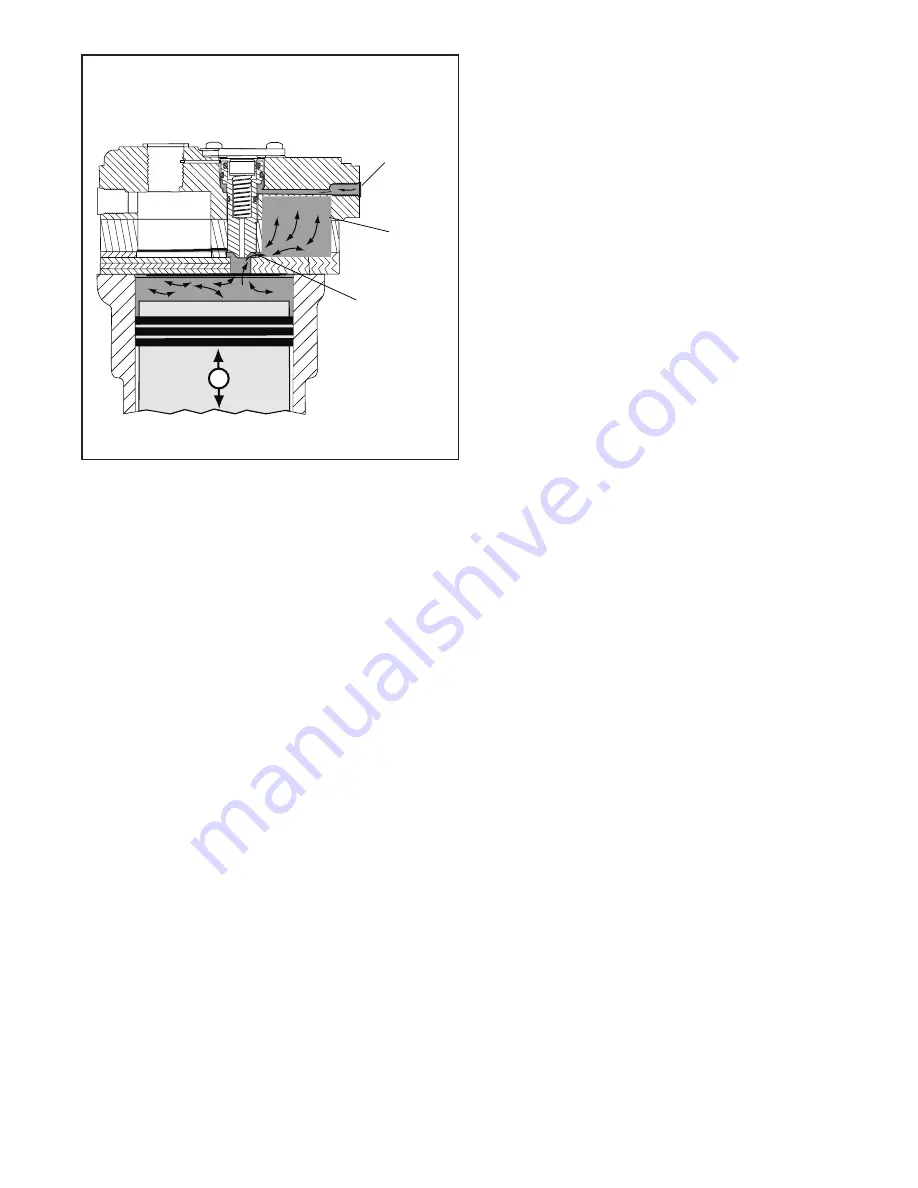

NON COMPRESSION OF AIR (UNLOADED)

When air pressure in the supply reservoir reaches the

cut-out setting of the governor, the governor delivers

system air to the compressor unloader port. Air entering

the unloader port acts on the unloader piston causing

the piston to move away from its seat on the valve plate

assembly. When the unloader piston is unseated, an air

passageway is opened between the cylinder bore and a

secondary compartment — or “closed room” — in the interior

of the cylinder head.

As the piston moves from Bottom Dead Center (BDC)

to Top Dead Center (TDC) air in the cylinder bore flows

past the unseated unloader piston, into the “closed

room”. The size of the closed room is sufficient to accept

the compressed air provided by the compressor piston

without creating excessive air pressure in the “closed

room”. On the piston down stroke (TDC to BDC) air flows

in the reverse direction — from the “closed room” past the

unseated unloader piston and inlet reed valve — and into

the cylinder bore. Note: For optimum performance, it is

recommended that the air dryer installed in the system

be equipped with a “turbo cut-off” feature.

See Figure 8.

LUBRICATION

The vehicle's engine provides a continuous supply of oil

to the compressor. Pressurized oil is routed from the

engine to the compressor's oil inlet port at the rear of the

crankcase. From there the oil flows through a passageway

on the inboard side of the crankcase to the front crankshaft

journal and sleeve bearing. An oil passage in the crankshaft

routes pressurized oil to the connecting rod journal and the

rear crankshaft journal. Spray lubrication of the cylinder

bores and connecting rod wrist pin bushings is obtained as

oil is forced out around the crankshaft journals by engine

oil pressure. Oil then falls to the bottom of the compressor

crankcase and is returned to the engine through drain holes

in the compressor mounting flange.

COOLING

Bendix

®

SNA-01

™

compressors are cooled by air flowing

through the engine compartment as it passes the

compressor's crankcase bore and by the flow of engine

coolant through the cylinder head. Coolant supplied by the

engine cooling system passes through connecting lines into

the cylinder head. It passes through internal passages in

the cylinder head, cooling plate, and valve plate assembly

and returns to the engine.

Figure 9 illustrates the coolant

port locations and proper flow path.

Proper cooling is

important in minimizing discharge air temperatures - see

the tabulated technical data in the compressor specification

section of this manual for specific requirements.

AIR INDUCTION

Bendix

SNA-01 air compressors are only permitted to be

naturally aspirated — use of engine turbocharger as an air

source is not allowed.

See Figure 5 for an example of a

naturally aspirated air induction system.

PREVENTIVE MAINTENANCE

Regularly scheduled maintenance is the single most

important factor in maintaining the air brake charging

system. Refer to Table A in the Troubleshooting section

of this manual, for a guide to various considerations that

must be given to maintenance of the compressor and other

related charging system components.

Important Note: Review the warranty policy before

performing any intrusive maintenance procedures. An

extended warranty may be voided if intrusive maintenance

is performed during this period.

FIGURE 8 -

OPERATION - UNLOADED

Air From

Governor

Unloader

Port

Air above the piston shuttles back and forth

between the cylinder bore and the closed room

Unloader

Piston Up &

Unseated

Closed

Room