2

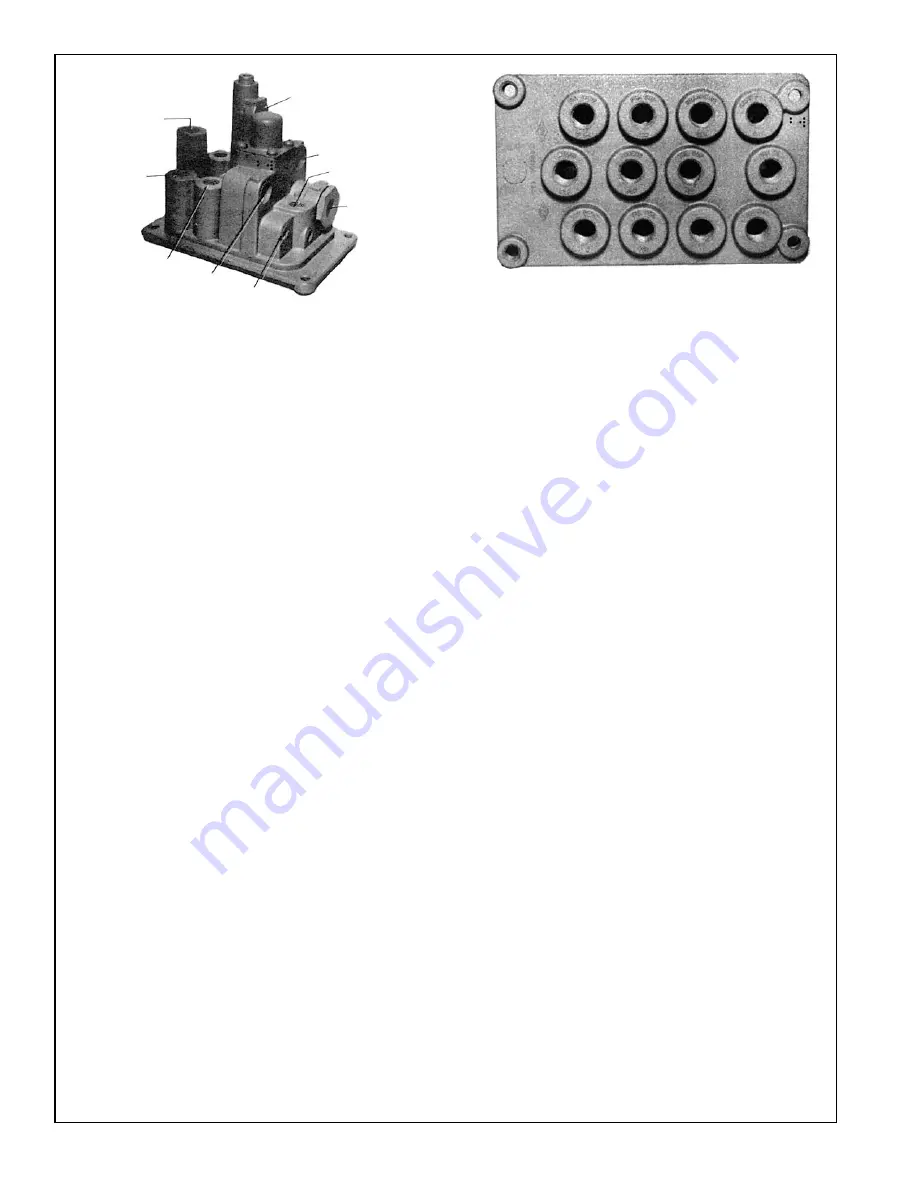

ENGINE SIDE

FIGURE 1

Port

Ident. on

No.

Casting

Function

1

Frt. Sup.

Supply from No. 2 circuit reservoir.

Blue

2

Park Sup.

Delivers air from double check valve

Red

area to spring brake relay valve (R-8).

3

Rear Sup.

Supply from No. 1 circuit reservoir.

Green

4

Rad. Fan

Delivers protected air supply from

Blk.

PR-4 valve. Suggested use - air

operated fan clutch.

5

Diff. Lock

Connects directly to port No. 9 (Fig.

Blk.

2) in cab. Suggested use - manifold

connection to differential lockout

mechanism. This is a 90

0

pass-through

passage.

6

Trl. Sup.

Connects directly to port No. 10 in

Yel.

cab. Suggested use - deliver air from

trailer supply valve (such as BW PP-7)

to trailer. This is a 90° pass-through

passage.

7

(None)

Connects directly to port No. 11 in

cab. Suggested use - any auxiliary

manifold function. This is a straight

through passage.

8

Air Rest.

Connects directly to port No. 12 in

Blk.

cab. Suggested use - air cleaner

restriction gauge. This is a straight

through passage.

9

Prk. Del.

Connects directly to port No. 8 (Fig.

Red

2) in cab. Suggested use - deliver air

from park control valve to spring

brake control valve (SR-1

™

valve).

This is a straight-through passage.

10

Spg. Brk.

Connects to secondary circuit reservoir

Rest. - Grn. and to port No. 4 (Fig. 2) in cab.

Suggested use - supplies secondary

reservoir air to the balance port of the

SR-1 spring brake control valve.

Port

Ident. on

No.

Casting

Function

1

Frt. Gauge

Connects to gauge for No. 2 circuit

Blue

reservoir.

2

Prk. Sup.

Supplies air from double check valve

Red

to park control valve.

3

Rear Gauge Connects to gauge for No. 1 circuit

Green

reservoir.

4

Hand Brake Supplies air from No. 2 circuit reservoir

Supply

to trailer hand control valve in

Green

cab. Connects with No. 10 on engine

side.

5

Access

Supplies protected air from PR-4

™

valve

Blk.

to any accessory control in cab.

6

Access

Supplies protected air from PR-4

™

valve

Blk.

to any accessory control in cab.

7

Trl. Sup.

Supplies air from double check valve

Red

to trailer supply valve (tractor

protection).

8

Prk. Del.

Receives air from delivery of park

Red

control valve to deliver to SR-1

™

spring

brake control valve. Connects with No.

9 on engine side.

9

Diff. Lock

Receives air from delivery of differen-

tial lockout control valve. Connects

with No. 5 on engine side.

10

Trl. Del.

Receives air from trailer supply valve

(tractor protection) to supply trailer.

Connects to No. 6 on engine side.

11

(None)

Auxiliary manifold for any accessory

function connects to No. 7 on engine

side.

12

Air Rest.

Suggested use - air cleaner restriction

Blk.

gauge. Connects with No. 8 on engine

side.

NO.1

NO.4

NO.2

NO.3

NO.9

NO.8

NO.7

NO.6

NO.5

1

2

3

4

5

6

7

8

9

10

11

12

CAB BULKHEAD SIDE

FIGURE 2