3

8. Use only genuine Bendix

®

replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

PREVENTIVE MAINTENANCE

Important:

Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the VM-3

™

manifold should be inspected every year or 3600 operating

hours, whichever comes first, for proper operation. Should

the VM-3

™

manifold not meet the elements of the operational

tests noted in this document, further investigation and service

of the valve may be required.

SERVICE CHECKS

OPERATING AND LEAKAGE CHECKS

1. Start engine and charge both sides of dual system.

2. Stop engine, drain the front brake reservoir and disconnect

tube fitting at port No. 1 in Fig. 1, identified as Frt.

Sup. - Blue. Excessive leakage would indicate a faulty

double check valve.

3. Restore and recharge both systems. Drain the rear brake

reservoir and disconnect the fitting at port No. 3 in Fig.

1, identified as Rear Sup. - Grn. Excessive leakage would

indicate a faulty double check valve.

4. After closing the drain cock and restoring the plumbing

for the front reservoir remove the fitting at port No. 4 in

Fig. 1. Start the engine and observe front dash gauge.

Stop the engine when the gauge shows 40 psi. Excessive

leakage from port No. 4 would indicate a faulty PR-4

™

valve. Restart engine and observe front gauge. Air should

start to blow from port No. 4 at 60-75 psi, indicating

PR-4

™

valve is operating correctly. With engine shut off,

PR-4

™

valve should close and retain at least 60 psi in

front reservoir.

If the VM-3

™

manifold does not function as described above

or leakage is excessive, it is recommended that it be returned

to the nearest Bendix authorized distributor for an exchange

or a replacement unit. If this is not possible, the unit can be

repaired with genuine Bendix parts in which case the following

should prove helpful. A field maintenance kit is available under

pc. no. 289062.

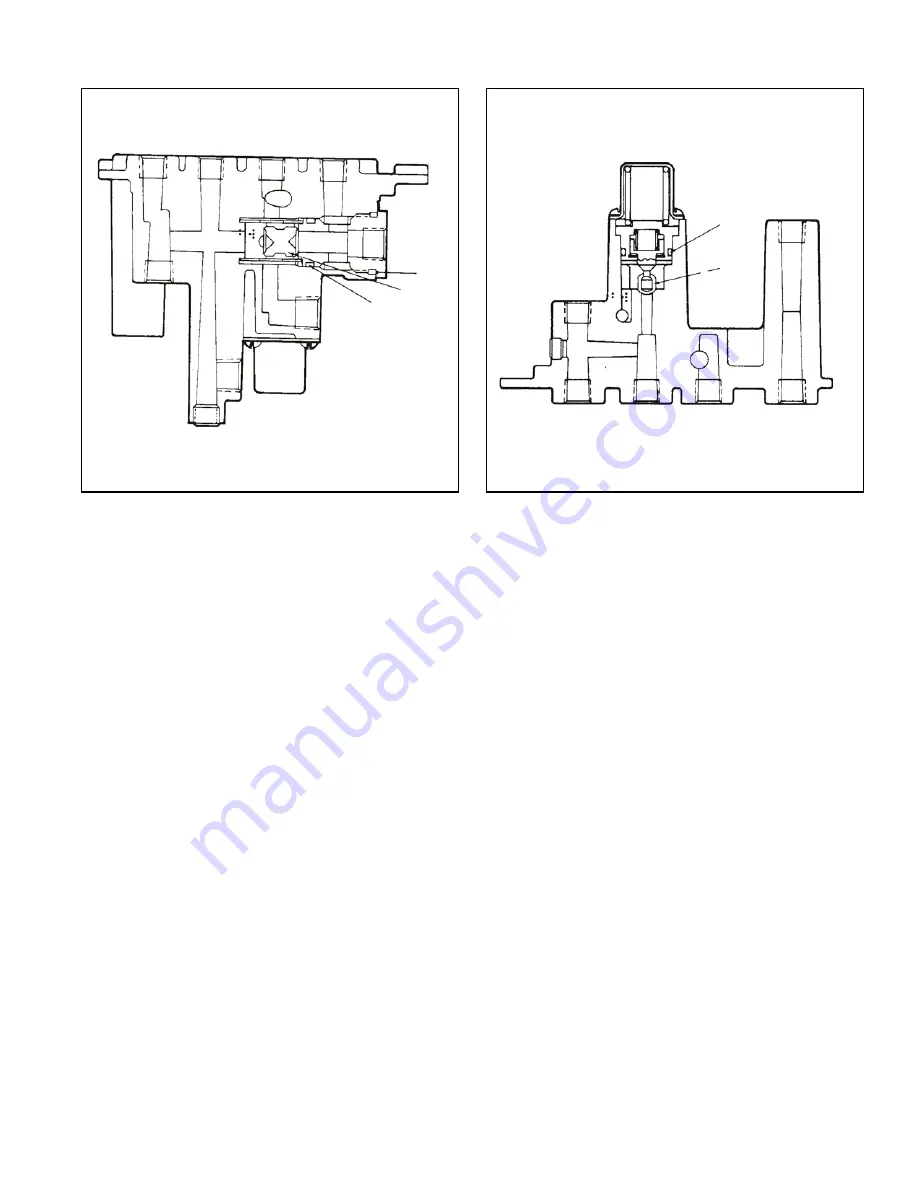

FIGURE 3

1

2

3

FIGURE 4

4

3