89000109-002

xVue Touch Installation Manual

Rev 2

Page 4-17

© Honeywell International Inc. Do not copy without express permission of Honeywell.

For Use in Non-Certified Aircraft

4.8.1 KDC 100EXP Installation Procedures

(1) Install the MD32 Magnetometer per the instructions in Appendix D.

(2) Ensure all wiring and power checks have been completed per Section 6.1.

(3) Ensure all power is removed from airplane.

(4) See Table 6-7 KMG 7010/MD32 Installation Orientation Options for mounting options and Figure

A-8 KMG 7010 Outline and Mounting Drawing (Sheet 1 of 2) for unit dimensions and center of

gravity information.

(5) Fabricate a mounting adapter plate (if needed).

(6) Prepare mounting hole locations as bonding points such that the bonding resistance conforms to

the guidelines listed in Section 3.10 Electrical Bonding Considerations. Ensure the installation

provides a 10.0 milliohm max impedance bond from the harness backshell to the airplane ground.

(7) Apply conversion coating material conforming to MIL-C-81706 per AC 43-13-1B, to exposed metal

surfaces.

(8) Install mounting adapter plate (as applicable).

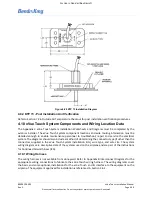

(9) Using the KDC 100EXP Installation Kit, mount the KDC 100EXP with the four #10-32 mounting

screws, washers and lock nuts (refer to Figure 4-16). Torque fasteners to 27.5 ± 2.5 in-lbs (3.11 ±

.28 Nm). All mounting hardware and brackets must be made from non-ferrous materials to avoid

interference with the magnetic field.

(10) Mount the KDC 100EXP on a rigid surface such that the three KDC 100EXP primary axes are paral-

lel within 5 degrees of the longitudinal, lateral, and vertical axes of the level airplane. The KDC

100EXP may be mounted parallel to the lateral (pitch), longitudinal (roll) or vertical (yaw) axis of

the airplane.

(11) Mount the KDC 100EXP on a rigid surface of the airplane and connect it to the MD32 Magnetome-

ter and KG 71EXP ADAHRS.

(12) Connect the J71 mating connector from the KG 71EXP wire harness to the KDC 100EXP. Torque

the two connector thumbscrews and torque to 4 ± 0.4 in-lbs (0.45 ± 0.05 Nm).

NOTE

SHIELD WIRING MUST REMAIN IN THE BACKSHELL (CONNECT TO GROUND LUG INSIDE

THE BACKSHELL).