BendPak, Inc.®

P/N 5905555

OPERATION / MAINTENANCE

INSTRUCTIONS - PLEASE READ

OPÉRATION / ENTRETIEN

INSTRUCTIONS - LISEZ S’IL VOUS PLAÎT

IMPORTANT

DANGER

Never lift any vehicle in any

manner with FEWER than (4)

arms. Rated capacity of each

lift arm is no greater than (1/4)

of the overall lifting capacity.

Ne jamais soulever un véhicule

de quelque manière que ce

soit avec moins de (4) bras. La

capacité nominale de chaque

bras de levage n’est pas

supérieure à (1/4) du capacité

de levage globale.

SUV & VAN ADAPTERS

VUS & ADAPTATEURS VAN

STEEL LIFT PADS

TAMPONS DE LEVAGE EN ACIER

REPLACEMENT

POLYURETHANE

TUF PADS™

REMPLACEMENT

POLYURÉTHANE

TUF PADS™

Steel lift pads are recommended for

additional stability on all vehicles.The

flanged edges grip the chassis for an

extra-secure hold.

Des coussinets de levage en acier

sont recommandés pour une stabilité

supplémentaire sur tous les véhicules.

Les bords à bride saisissent le châssis

pour une prise extra-sûre.

Required for use when lifting

trucks, vans or other frame

vehicles that require additional stability.

Requis pour être utilisé lors du levage

camions, fourgonnettes ou autre châssis

véhicules qui nécessitent une stabilité

supplémentaire.

Recommended for use when

lifting heavy-duty wide frame vehicles.

Fits wide frames up to 5.25 in.

Recommandé pour une utilisation

lorsque levage de véhicules lourds à

châssis large. Convient aux cadres

larges jusqu’à 133.35mm.

NEVER use lift with missing or

damaged rubber contact pads.

ALWAYS REPLACE rubber

contact pads when worn or damaged

.

NE JAMAIS utiliser d’élévateur avec

patins de contact en caoutchouc

endommagés. REMPLACEZ TOUJOURS le

caoutchouc tampons de contact lorsqu’ils

sont usés ou endommagés.

Recommended for trucks,

SUVs and vans that require

additional lifting height.

Recommandé pour les camions,

VUS et fourgonnettes nécessitant

hauteur de levage supplémentaire.

FRAME CRADLE

ADAPTERS

ADAPTATEURS DE CADRE

DE CADRE

WIDE FRAME

CRADLE ADAPTERS

CADRE LARGE ADAPTATEURS

DE BERCEAU

SKU# 5215761

SKU# 5215761

(Set of 4)

(Ensemble de 4)

SKU# 5215848

SKU# 5215848

SKU# 5215692

SKU# 5215692

SKU# 5715017

SKU# 5715017

63 mm

125 mm

SKU# 5746192

SKU# 5746193

56 mm

SKU# 5746007

USE PROPER ADAPTERS

Do not attempt to lift trucks or other frame type

vehicles with standard rubber contact pads. NEVER

use lift with missing or damaged rubber contact

pads. ALWAYS REPLACE rubber contact pads when

worn or damaged. Contact BendPak or your BendPak

dealer for product information.

UTILISEZ DES ADAPTATEURS APPROPRIÉS

N’essayez pas de soulever des camions ou d’autres véhicules à

châssis avec des patins de contact en caoutchouc standard. NE

JAMAIS utiliser d’élévateur avec des coussinets en caoutchouc

manquants ou endommagés. TOUJOURS REMPLACER les

coussinets de contact en caoutchouc lorsqu’ils sont usés ou

endommagés. Contactez BendPak ou votre revendeur BendPak

pour obtenir des informations sur le produit.

ATTENTION

CAUTION

MISE EN GARDE

LIFT OPERATION

OPÉRATION DE LEVAGE

WARNING

ATTENTION

TO RAISE LIFT

3

Read Operating and Safety manuals before using lift.

3

Always lift vehicle according to manufacturer’s recommended

lifting points.

3

Position vehicle between columns. Adjust swing arms so that

vehicle is positioned with the center of gravity midway

between pads.

3

Position lift contact pads at manufacturer’s recommended

lifting points.

3

Use truck adapters as needed. Never exceed 9" of pad/adapter

height.

3

Raise lift by pressing RAISE BUTTON on power unit until

contact pads make contact with the underside of the vehicle.

3

Recheck to make sure vehicle is secure.

3

Raise vehicle to desired working height, then press power

unit LOWERING HANDLE until lift carriages rest onto nearest

safety lock position.

3

Maintain visual contact with vehicle and surrounding area at all

times while raising lift.

3

STOP IMMEDIATELY if load shifts or becomes unlevel.

3

Always ensure safety locks are engaged before any attempt is

made to work on or near vehicle.

3

Always ensure lift contact pads are making full contact with

vehicle before any attempt is made to work on or near vehicle.

TO LOWER LIFT

3

Raise lift by pressing RAISE BUTTON on power unit.Elevate

lift at least two inches to allow adequate clearance for the

locks to clear.

3

Clear safety locks by maintaining pressure on SAFETY LOCK

RELEASE HANDLE to its furthest travel.

3

Be sure tool trays, stands or personnel are removed from

under vehicle.

3

Lower vehicle by pressing power unit lowering handle

until lift has descended completely.

3

Maintain visual contact with vehicle and surrounding area at all

times while lowering lift.

3

STOP IMMEDIATELY

if load shifts or becomes unlevel.

3

Before removing vehicle from lift area, position lift arms to

provide unobstructed exit.

3

NEVER drive over lift arms.

REQUIRED MONTHLY MAINTENANCE

3

ALWAYS consult operation manual for factory-recommended

maintenance.

3

Check arm restraints for proper operation.

3

Check all chain/cable connections, bolts and pins to ensure

proper mounting.

3

Visually inspect safety locks for proper operation.

3

Visually inspect concrete floor. DO NOT USE LIFT if concrete

foundation shows signs of deterioration.

3

Inspect all anchor bolts and retighten if necessary.

3

Check columns for square, plumb positioning.

3

Inspect all pivot pins, making sure they are properly secured.

3

Check equalizer cable tension – cables must have equal

tension. Adjust if necessary.

3

Inspect all lift pads, replace if necessary.

3

If lift is equipped with overhead cut-off switch, check for

proper operation.

WARNING!

1.

WARNING:

If cement anchor bolts are loose or any component

of the lift is found to be defective,

DO NOT USE LIFT!

2. Never operate the lift with any person or equipment below.

3. Never exceed rated capacity.

4. Always ensure safety locks are engaged before any attempt

is made to work on or near vehicle.

5. Never leave lift in an elevated position unless the safety locks

are engaged.

6. Do not permit electric motor to get wet! Motor damage caused

by dampness is not covered under warranty.

POUR SOULEVER

3

Lisez les manuels d’utilisation et de sécurité avant d’utiliser l’ascenseur.

3

Toujours soulever le véhicule conformément aux points de levage

recommandés par le fabricant.

3

Positionner le véhicule entre les colonnes. Ajustez les bras pivotants

de sorte que le véhicule soit positionné à mi-chemin du centre de

gravité entre les pads.

3

Positionnez les électrodes de contact aux points de levage

recommandés par le fabricant.

3

Utilisez des adaptateurs de camion au besoin. Ne dépassez jamais 9

“de hauteur de pad / adaptateur.

3

Soulevez l’élévateur en appuyant sur le bouton-poussoir RAISE

du bloc d’alimentation jusqu’à ce que les électrodes de contact

soient en contact avec la face inférieure du véhicule.

3

Revérifiez pour vous assurer que le véhicule est sécurisé.

3

Soulever le véhicule à la hauteur de travail souhaitée, puis appuyer sur

le levier de commande LOWERING POIGNER jusqu’à ce que les chariots

reposent sur la position de verrouil lage de sécurité la plus proche.

3

Maintenir le contact visuel avec le véhicule et la zone environ nante à

tout moment pendant la montée.

3

ARRÊTEZ IMMÉDIATEMENT si la charge change ou devient inégale.

3

Assurez-vous toujours que les verrous de sécurité sont serrés

avant toute tentative de travail sur ou à proximité du véhicule.

3

Assurez-vous toujours que les coussinets de contact de l’as

censeur sont complètement en contact avec le véhicule avant

de tenter de travailler sur ou à proximité du véhicule.

ABAISSER ASCENSEUR

3

Soulevez l’élévateur en appuyant sur le bouton RAISE du bloc

d’alimentation. Soulevez l’ascenseur d’au moins deux pouces pour

permettre un dégagement suffisant des serrures.

3

Supprimez les verrouillages de sécurité en maintenant la pression sur

le levier de déverrouillage du verrou de sécurité jusqu’à sa course la

plus éloignée.

3

Assurez-vous que les plateaux à outils, les supports ou le personnel

sont retirés du dessous du véhicule.

3

Abaisser le véhicule en appuyant sur la poignée d’abaissement du

groupe moteur jusqu’à ce que l’élévateur soit complètement descendu.

3

Maintenir le contact visuel avec le véhicule et la zone environnante à

tout moment lors de l’abaissement de l’ascenseur.

3

ARRÊTEZ IMMÉDIATEMENT

si la charge change ou devient inégale.

3

Avant de retirer le véhicule de la zone de levage, positionnez les bras

de levage pour permettre une sortie dégagée.

3

NE conduisez JAMAIS sur les bras de levage.

ENTRETIEN MENSUEL REQUIS

3

Consultez TOUJOURS le manuel d’utilisation pour la maintenance

recommandée par l’usine.

3

Vérifier le bon fonctionnement des appuis-bras.

3

Vérifiez toutes les connexions de la chaîne / du câble, les boulons et

les broches pour assurer un montage correct.

3

Inspectez visuellement les serrures de sécurité pour vous assurer

qu’elles fonctionnent correctement.

3

Inspecter visuellement le sol en béton. NE PAS UTILISER LIFT si

la fondation en béton montre des signes de détérioration.

3

Inspectez tous les boulons d’ancrage et resserrez si nécessaire.

3

Vérifiez les colonnes pour le positionnement carré, d’aplomb.

3

Inspectez tous les axes de pivot en vous assurant qu’ils sont

correctement fixés.

3

Vérifiez la tension du câble d’égalisation - les câbles doivent avoir une

tension égale. Ajustez si nécessaire.

3

Inspectez tous les coussins de levage, remplacez-les si nécessaire.

3

Si l’ascenseur est équipé d’un interrupteur de protection en hauteur,

vérifiez son bon fonctionnement.

ATTENTION!

1. ATTENTION:

Si les boulons d’ancrage en ciment sont desserrés ou si l’un

des composants de l’élévateur est défectueux,

N’UTILISEZ PAS LIFT!

2. N’utilisez jamais l’ascenseur avec une personne ou un équipement

ci-dessous.

3. Ne dépassez jamais la capacité nominale.

4. Assurez-vous toujours que les verrous de sécurité sont enclenchés

avant de tenter de travailler sur ou à proximité du véhicule.

5. Ne laissez jamais l’ascenseur en position élevée à moins que les

verrous de sécurité ne soient engagés.

6. Ne laissez pas le moteur électrique se mouiller! Les dommages au

moteur causés par l’humidité ne sont pas couverts par la garantie.

WIRE ROPE INSPECTION AND MAINTENANCE

• Lifting cables should be replaced if wear or damage is

evident such as excessive broken strands, kinks, deformities,

or areas of heavy abrasion.

• Wire rope should be maintained in a well-lubricated

condition at all times. Wire rope is only fully protected when

each wire strand is lubricated both internally and externally.

Excessive wear will shorten the life of the wire rope. The

factory suggests wire rope lubricant that penetrates to the

core of the rope and provides long-term lubrication between

each individual strand. In order to make sure that the inner

layers of the rope remain well-lubricated, lubrication should

be carried out at intervals not exceeding three (3) months

during operation.

• All sheaves and guide rollers in contact with the moving

wire rope should be given regular visual checks for surface

wear and lubricated to make sure that they run freely. This

operation should be carried out at appropriate intervals

generally not exceeding three (3) months during operation.

For all sheave axles, the factory recommends standard

wheel bearing grease. For all sheaves and/or guide rollers,

the factory recommends 90-WT gear oil or similar heavy

lubricant applied by any method, including pump/spray

dispensing, brush, hand and/or swabbing.

INSPECTION ET MAINTENANCE DES CÂBLES

• Les câbles de levage doivent être remplacés si l’usure ou des

dommages sont évidents, tels que des brins cassés, des pliures, des

déformations ou des zones de forte abrasion excessives.

• Le câble métallique doit être maintenu dans un état bien lubrifié en

tout temps. Le câble métallique n’est entièrement protégé que lorsque

chaque toron est lubrifié à l’intérieur et à l’extérieur. Une usure

excessive raccourcira la durée de vie du câble. L’usine propose un

lubrifiant pour câble métallique qui pénètre jusqu’au noyau du câble

et assure une lubrification à long terme entre chaque toron. Afin de

s’assurer que les couches internes du câble restent bien lubrifiées,

la lubrification doit être effectuée à des intervalles ne dépassant pas

trois (3) mois pendant le fonctionnement.

• Toutes les poulies et les galets de guidage en contact avec le câble

en mouvement doivent être soumis à des contrôles visuels réguliers

de l’usure de la surface et lubrifiés pour s’assurer qu’ils fonctionnent

librement. Cette opération doit être effectuée à des intervalles

appropriés n’excédant généralement pas trois (3) mois pendant le

fonctionnement. Pour tous les essieux de poulies, l’usine recommande

la graisse standard pour roulements de roue. Pour toutes les poulies

et / ou les galets de guidage, l’usine recommande une huile pour

engrenages 90-WT ou un lubrifiant lourd similaire, quelle que soit

la méthode utilisée, notamment la distribution par pompe / spray,

brosse, main et / ou écouvillonnage.

Long-wheelbase vehicles

can damage lift and/or

cause personal harm or

injury to operators if loaded

incorrectly. All vehicles MUST

be positioned on lift with

CENTER OF GRAVITY midway

between adapters.

Les véhicules à empattement

long peuvent endommager

l’élévateur et / ou causer des

blessures corporelles aux

opérateurs s’ils sont chargés

de manière incorrecte. Tous

les véhicules DOIVENT être

placés sur l’élévateur avec

CENTRE DE GRAVITÉ à mi-

distance entre les adaptateurs.

TO PLACE ORDER

Visit www.bendpak.com

or dial 1-805-933-9970

Monday - Friday

6 a.m. - 4:30 p.m. PT

POUR COMMANDER

Visite www.bendpak.com

ou composez 1-805-933-9970

Lundi - Vendredi

6h du matin - 16h:30 TP

(Set of 2)

(Ensemble de 2)

WARNING

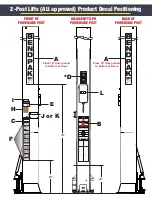

2-Post Lifts (ALI approved) Product Decal Positioning

A

B

BPK Post Lift Decal.pdf

Material: Clear Adhesive PET

Size: 4.25"W x 38"H

Thickness: 4 Mil

Finish: Matte Overlaminate (No

Gloss)

Ink: U.V. protected, Opaque White

Print Process: Silk Screen, 85

line-screen

(Yellow color in file

represents what should be clear

PET material and SHOULD NOT

print as Yellow ink. White area in

file represents Opaque White ink.)

Lamination: Clear Laminate non-

glare medium matte over laminate

for abrasion, chemical, and ultra

violet protection.

P/N 5905311

P/N 5905555

NOTE:

Place adjacent to power unit

below safety lock release

handle

Total of 4

XPR-S_Series_2-Post_Safety_

Decal-FRE-ENG-5905555.pdf:

Size: 8.5"W x 35.75"H

Material: White Vinyl Pressure

Sensitive Adhesive

Thickness: 4 Mil

Ink: U.V. protected CMYK 2/C

Process

Finish: Matte Overlaminate (No

Gloss)

Print Process: Offset Lithography

- 200 line-screen or 300 p.p.i. for

digital

Lamination: Clear Laminate non-

glare medium matte over laminate

for abrasion, chemical, and ultra

violet protection.

C

P/N 5905940

Product_Data_Label_5905940.pdf:

Size: 4.5"W x 2.75"H

Material: White Vinyl Pressure Sensitive

Adhesive

Thickness: 4 Mil

Ink: U.V. protected CMYK 2/C Process

Finish: Matte Overlaminate (No Gloss)

Print Process: Offset Lithography - 200 line-

screen or 300 p.p.i. for digital

Lamination: Clear Laminate non-glare medium

matte over laminate for abrasion, chemical,

and ultra violet protection.

Safety Instructions

: If attachments, accessories, or configuration-modifying components that are

located in the load path affect operation of the lift, affect the lift electrical listing, or affect intended

vehicle accommodation are used on this lift and, if they are not certified for use on this lift, then the

certification of this lift shall become null and void. Contact the participant for information pertaining

to certified attachments, accessories, or configuration-modifying components.

BendPak

lifts are supplied with concrete fasteners meeting the criteria as prescribed by ASTM E488/

E488M-18. Lift buyers are responsible for any special regional, structural, and/or seismic anchoring

requirements specified by any other agencies and/or codes such as the Uniform Building Code (UBC)

and/or International Building Code (IBC).

The manufacture, use, sale, or import of this product may be subject to one or more United States

patents, or pending applications, owned by

BendPak Inc.

1645 Lemonwood Dr.

Santa Paula, CA USA

www.BendPak.com

LIFT TYPE:

Surface Mount

MANUFACTURER:

BendPak. See data plate for product details

POWER:

Electric/Hydraulic

INSTALLATION:

See manual or contact factory

Do Not Remove

Engineered by BendPak Inc., USA

Made in China

PN 5905940

CLEAR ADHESIVE PET

DOES NOT PRINT YELLOW