47

MotoR WILL Not RuN

possible cause

1. Fuse blown, (5,2,1,3,4)

2. Limit switch burned out, (1,2,3,4)

3. Microswitch burned out, (1,2,3,4)

4. Motor burned out, (1,2,3,4,6)

5. Voltage to motor incorrect, (2,1,8)

remedy

insTrucTion

1. Check for correct voltage . . . . . . . . . . . . . . . . . . . . . . . . . . .Compare supply voltage with voltage on motor

name tag. Check that the wire is sized correctly.

N.E.C. table 310-12 requires AWG 10 for 25 Amps.

2. Check motor is wired correctly . . . . . . . . . . . . . . . . . . . . . . .Compare wiring of motor to electrical diagram on

drawing.

3. Don’t use extension cords . . . . . . . . . . . . . . . . . . . . . . . . . . According to N.E.C. : “ The size of the conductors…

should be such that the voltage drop would not exceed

3% to the farthest outlet for power…” Do not run motor

at 115 VAC – damage to the motor will occur.

4. Replace with new part . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Replace with new part.

5. Reset circuit breaker/fuse . . . . . . . . . . . . . . . . . . . . . . . . . .Reset circuit breaker/fuse.

6. Return unit for repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Return unit for repair.

7. See Installation Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . .See Installation Manual.

8. Check wall outlet voltage and wiring . . . . . . . . . . . . . . . . . . Make sure unit and wall outlet is wired properly. Motor

must run at 208/230 VAC.

LIFt LoWERS SLoWLy oR Not At ALL

possible cause

1. Cylinders binding, (1)

2. Release valve clogged, (5,4,2,3)

3. Pressure fitting too long, (6)

remedy

insTrucTion

1. See Installation Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . Consult Lift Manufacturer.

2. Replace with new part . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace with new part.

3. Return for repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Return for repair.

4. Check oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Use clean 10-WT hydraulic oil or Dexron-III automatic

transmission fluid only. If ATF is contaminated, replace

with clean ATF and clean entire system.

5. Clean release valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Wash release valve in solvent and blow out with air.

6. Replace fitting with short thread lead . . . . . . . . . . . . . . . . . . . Replace fitting with short thread lead.

47

Summary of Contents for XpR-10AC-168

Page 25: ...25 25 ...

Page 28: ...28 ...

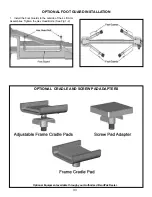

Page 32: ...32 32 OPTIONAL EQUIPMENT INSTALLATION ...

Page 42: ...42 42 ...

Page 43: ...43 43 ...

Page 52: ...52 52 ...

Page 74: ...74 ...

Page 75: ...75 ...