56

56

DIMENSIONS ARE IN MM

☺

3

4

1

2

REVISION

REV

DESCRIPTION

EDITED BY

A

PRODUCTION RELEASE, DERIVERD FROM XPR-10C

02/16/2010

00293

B

UPDATED BOM REVISIONS

04/15/2010

00346

ITEM

PART

NUMBER

DESCRIPTION

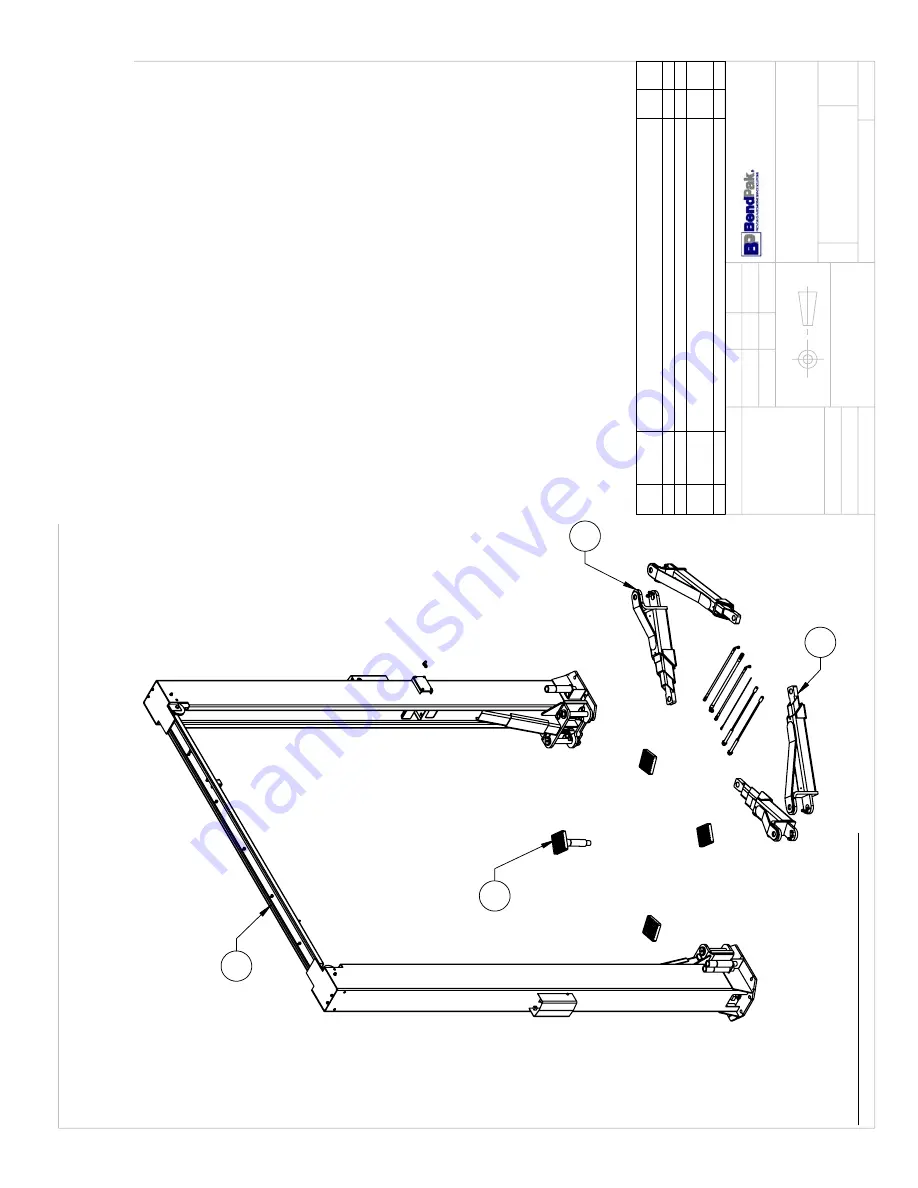

1

5245133

XPR-10C LIFT SUPERSTRUCTURE

1

B

2

5250233

XPR-10C PARTS BOX

1

B

3

5210170

XPR-9F/FD/FS/ 10C/AC LOW PROFILE TRIPLE

TELESCOPING ARM ASSEMBLY

2

A

4

5215195

XPR-9/10C/CX LOW PROFILE MEDIUM ARM ASSEMBLY

2

A

SHEET 1 OF 2

DWG. NO.

A

TITLE:

CHECKED

DRAWN

SIZE:

MATERIAL:

B

1645 LEMONWOOD DR. SANTA PAULA, CA 93060

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF

BENDPAK INC.

ANY

REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF

BENDPAK INC.

PROHIBITED.

NOTE: UNLESS OTHERWISE SPECIFIED

.

5260139

XPR-10C RECEIVED LIFT

02/16/2010

DO NOT SCALE DRAWING

SCALE:

THIRD ANGLE PROJECTION

04/30/2010

SEE SHIPPING INSTRUCTIONS FOR FINAL PACKAGING

Summary of Contents for XpR-10AC

Page 23: ...23 23 ...

Page 26: ...26 ...

Page 30: ...30 30 OPTIONAL EQUIPMENT INSTALLATION ...

Page 40: ...40 40 ...

Page 41: ...41 41 ...

Page 49: ...49 49 ...