10

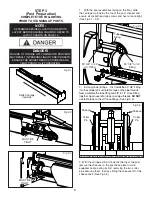

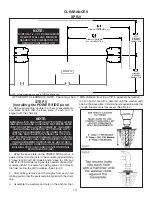

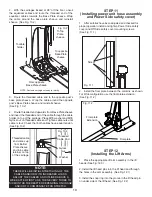

4. Identify the correct cable button on the end of each

equalizer cable that corresponds to your desired lift con-

fi guration. (See Fig 3.6) Secure the correct cable button at

the carriage lock plate located inside each carriage.

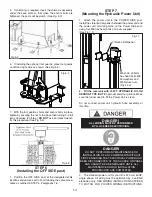

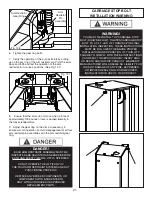

5. Route the correct button end of the equalizer cable

for your chosen lift layout through the cable retainer,

located inside the carriage on the front carriage tube wall,

up to where the Top Plate sheave would be, and coil the

remaining cable up and leave it in the post above the car-

riage. (See Fig 3.7-3.8)

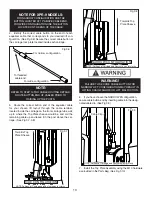

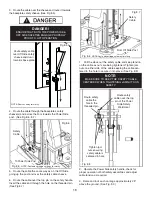

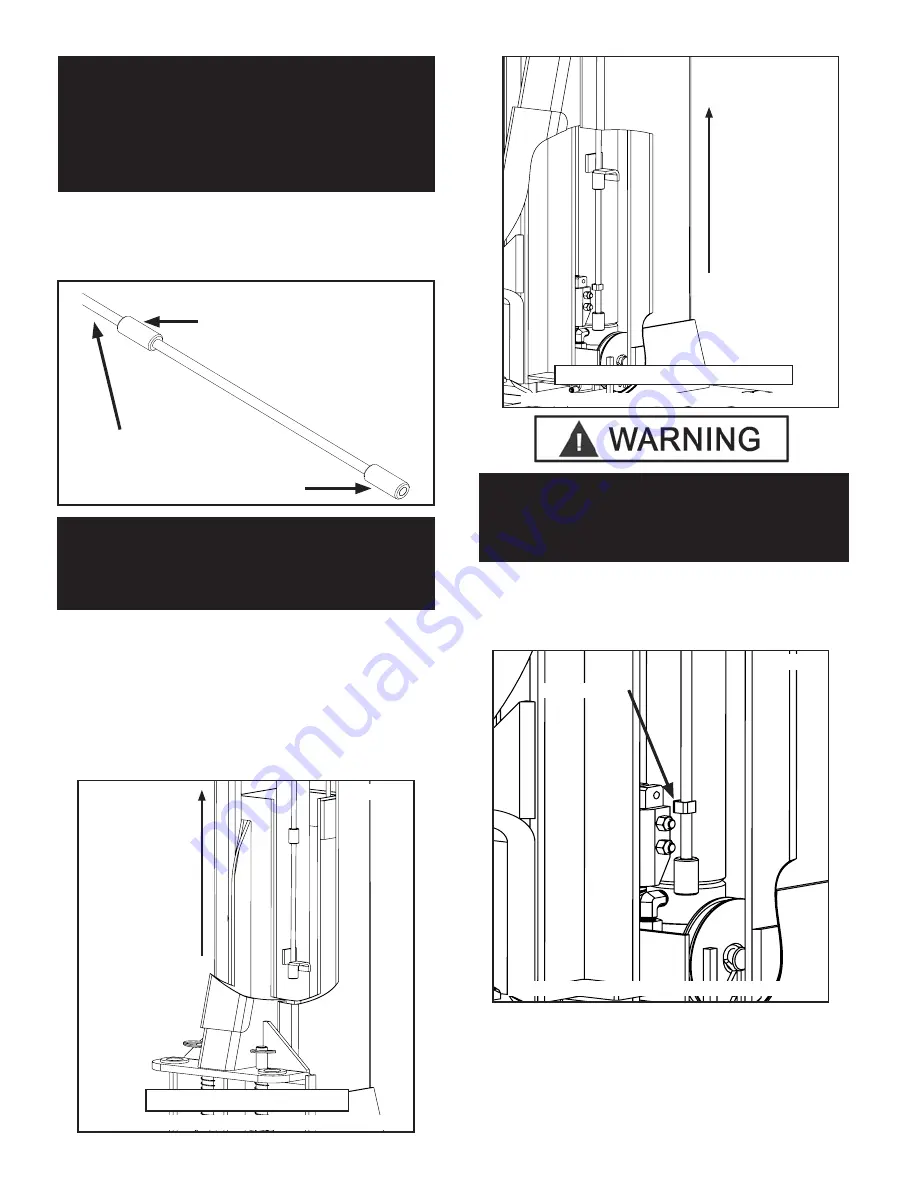

6. If you have chosen the NARROW lift confi guration,

secure cable button end by inserting cable into the desig-

nated cable clip. (See Fig 3.9)

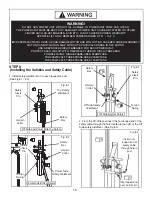

7. Install the Top Plate Assembly using the M10 hardware

as provided in the Parts Bag. (See Fig 3.10)

NOTE FOR XPR-9 MODELS:

FOR NARROW CONFIGURATION USE THE

BUTTON LOCATED AT 12” ABOVE CABLE END.

FOR WIDE CONFIGURATION USE THE BUTTON

LOCATED ON THE END OF THE CABLE.

For narrow confi guration

For wide confi guration

To threaded

cable end

Fig 3.6

NOTE:

REFER TO STEP 10 FOR CABLE ROUTING DETAILS.

ROUTE BUTTON END OF CABLES PRIOR TO

RAISING UP THE POSTS.

WARNING!

FAILURE TO SECURE CABLE BUTTON FOR

NARROW LIFT CONFIGURATION MAY RESULT IN

LIFTING CHAIN FAILURE OR LIFT MALFUCTION.

Fig 3.9

Cable Clip

NOTE: Portions of Carriage and Post cut away for clarity

Fig 3.8

Towards Top

Plate Sheave

NARROW CONFIGURATION

NOTE: Portions of Carriage and Post cut away for clarity

Fig 3.7

Towards Top

Plate Sheave

WIDE CONFIGURATION

NOTE: Portions of Carriage and Post cut away for clarity