Optional accessories are available for a surcharge!

5. Placing and installation of the boiler

5.1. Regulations and directives

The heating boiler may be installed only by an authorized service company that has been

certified for assembly of such devices. A project of the system must be prepared, respecting all

valid regulations.

The heating system must be filled with water that matches the standard ČSN 07 7401:1992. Especially

the water hardness shouldn’t exceed the required parameters.

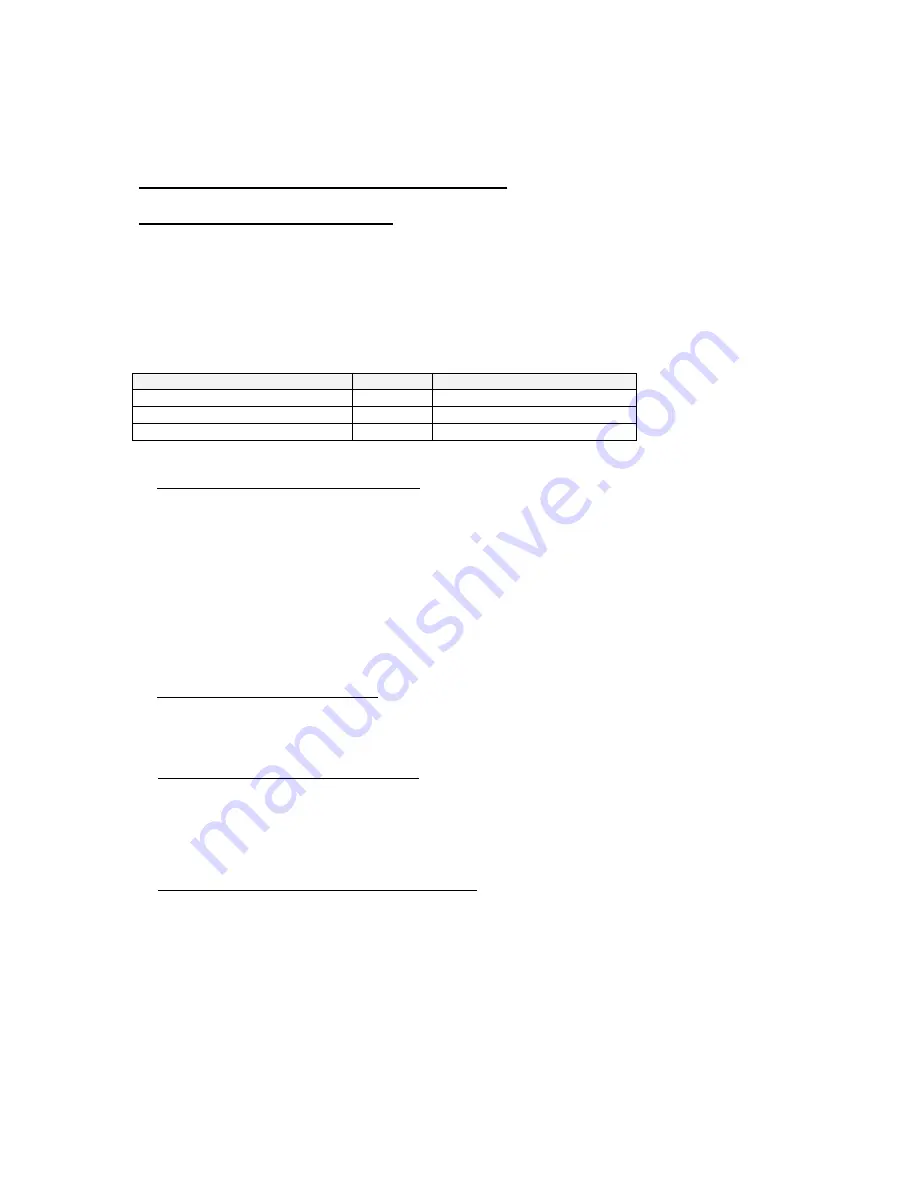

Table 5: Parameters of the heating water

Parameter

Unit

Value

Hardness

mmol/l

1

Ca

2+

mmol/l

0,3

Total Fe + Mn concentration

mg/l

0,3 (recommended value)

A) regulations concerning the heating system

ČSN EN 303-5:2013

Central heating boilers - part 5: Central heating boilers for solid

fuel with manual or automatic supply of fuel with nominal power

up to 500kW - terminology, requirements, proofing and marking.

ČSN 06 0310: 2006

Heating systems in buildings - projects and

installation.

ČSN 06 0830: 2006

Heating systems in buildings - safety devices

ČSN 07 7401: 1992

Water and steam in thermal energetic devices operating with

the running pressure to 8 Mpa.

B) regulations concerning the chimney

ČSN 73 4201:2010

Chimneys and smoke flues

– projects, realization

and connection of fuel appliances.

C) regulations concerning the fire regulations

ČSN 06 1008:1997

Fire safety of heating installations.

ČSN EN 13 501-1-1+A1:2010 Fire safety classification of construction products and buildings

constructions

– Part 1: Classification according to results of

reaction to fire tests

D) regulations concerning the electrical power network

ČSN 33 0165:1992

Electric regulations. Marking of conductors with colours or

numbers. Implementary regulations.

ČSN 33 1500:1990

Electric regulations. Revision of electric appliances.

ČSN 33 2000-1 ed.2:2009

Low voltage electric installations. Part 1: Basic principles,

determination of basic characteristics, definitions.

ČSN 33 2000-4-41 ed.2:2007 Low voltage electric installations - Part 4-41:

Protection measures to ensure safety

– Protection

from electrical injury.

ČSN 33 2000-5-51 ed.2:2006 Electrical installations in buildings – Part 5-51: Choosing and

building of electrical devices - General principles

Summary of Contents for R100

Page 1: ...1 SERVICE AND INSTALLATION MANUAL FOR CENTRAL HEATING BOILER BENEKOV R100 ...

Page 8: ...Fig 2 Basic dimensions of BENEKOV R100 boiler ...

Page 9: ...Fig 3 Basic dimensions of BENEKOV R100 boiler with additional module of fuel bin ...

Page 30: ...30 Declaration of conformity of boiler BENEKOV R 100 ...

Page 31: ...31 Original ES declaration of conformity of boiler BENEKOV R 100 ...