18

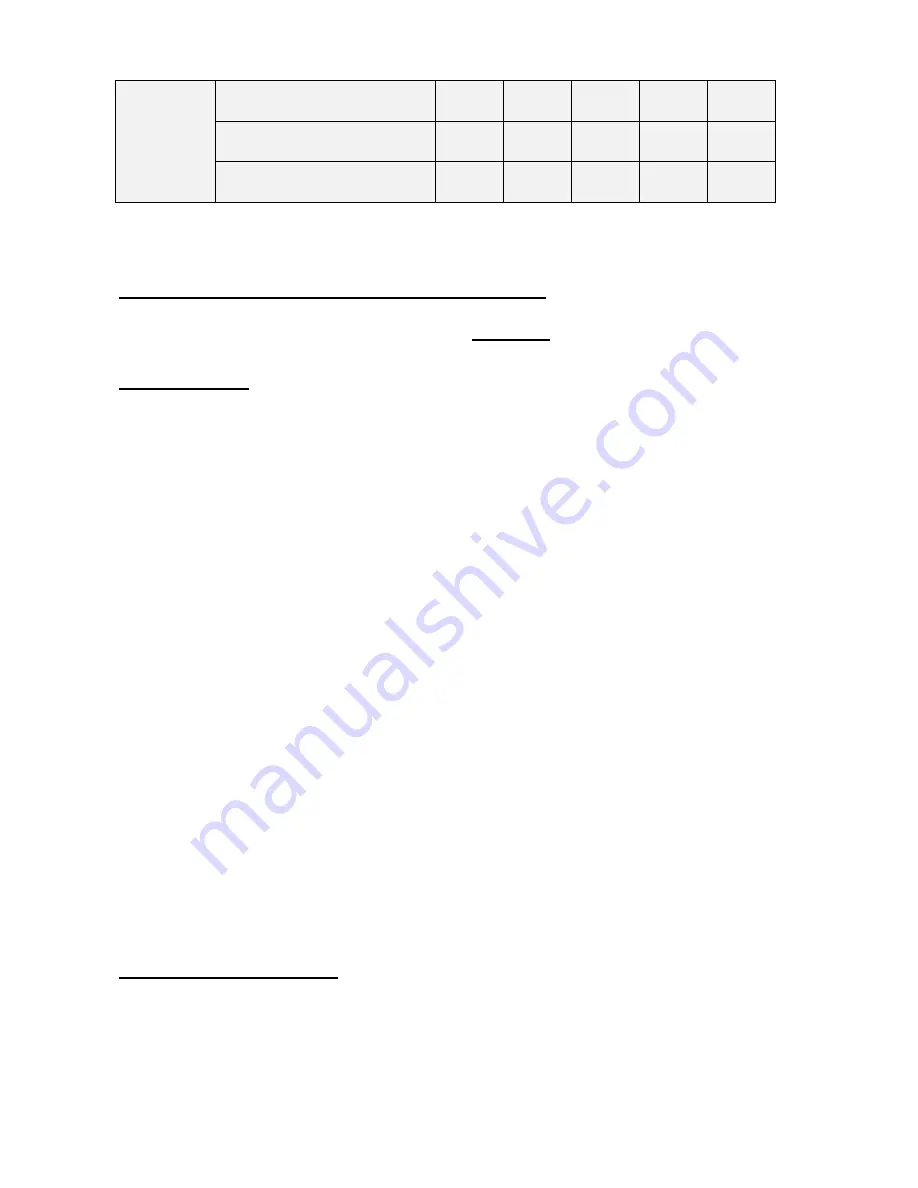

Arrangement with 3 m feeder

3000

4836

2456

2374

226

Arrangement with 4 m feeder

4000

5821

3441

2374

52

φ

2500 mm

(4000 dm

3

)

Arrangement with 5 m feeder

5000

6806

4426

2374

-122

* Dimension "A" is specified by the client when ordering, based on the specific boiler room design.

4.2. Control and safety elements of the boiler

The control and regulation of the boiler is governed by a control unit - see separate instruction manual.

Safety components that monitor the safe operation of the boiler:

•

The emergency thermostat is used to prevent the system from overheating. The manufacturer sets

the thermostat at 95°C, i.e. at a higher temperature than can be set on the boiler. The emergency

thermostat is positioned on the rear wall of the boiler in the CLIMATIX control unit cabinet.

•

Thermal protection of the motor (thermal contact) is part of both fuel feeder motors and is used to

protect them from overheating in the case of fuel feeder blockage. It also retroactively stops the fan so

as to avoid burning of fuel in the container in the event of a fault. During normal operation, the motor

working temperature is up to 85 °C - such warming does not mean a failure.

•

The turnstile is a device that mechanically separates the fuel between the screw conveyors (feeding

from the bunker + feeding into the boiler). In the event of re-ignition of fuel in the boiler feeding (e.g.

during long term power outage) the fuel in the tank does not ignite. Furthermore, the turnstile serves as

a partial fuel crusher. In the event of a longer piece reaching the turnstile, the turnstile crushes it into

smaller pieces.

•

The cover limit switch of the bunker feeder shuts down the screw feeder and fan when the cover is

open. After proper closure both will return to normal operation.

•

The emergency fire extinguishing system is another security feature preventing burning of fuel

through to the container. A temperature increase above 95 °C at the feeding out of the bunker results in

a thermostatic valve opening and the space being cooled with cooling water from the water main.

•

The firing flap is located between the second and the third draft in the top part of the finned heat

exchanger and serves to regulate the flue gas temperature at the boiler outlet.

When operating the boiler when the flue gas temperature is higher than 100 °C the firing valve must be

closed, i.e. the firing flap lever on the side of the boiler must be rotated as much as possible upwards

(forwards) and secured with a locking screw. When firing (with cold chimney) or during long term

operation of the boiler at lower output it is recommended to operate the boiler with the firing valve

slightly open so that the flue gas temperature does not drop below 80 °C. In this case, the firing flap

lever must be rotated downward (backwards) and secured by a locking screw.

4.3. Boiler accessories

Standard accessories:

•

Operating instructions and installation manual which includes a warranty card

•

Operating instructions of the boiler control unit

•

List of contracted service organizations

Summary of Contents for S16

Page 1: ...BOILER OPERATING AND INSTALLATION INSTRUCTION MANUAL BENEKOV S16 BENEKOV S26 BENEKOV S51 ...

Page 20: ...20 Fig no 14 Boiler ash remover for S51 Fig no 15 Boiler flue gas exhaust for S16 and S26 ...

Page 27: ...27 Fig no 22 Connection dimensions of BENEKOV S26 boiler ...

Page 28: ...28 Fig no 23 Connection dimensions of BENEKOV S51 boiler ...