5 - 63

C

A

OIL PUMP REMOVAL

LUBRICATION SYSTEM

B

C

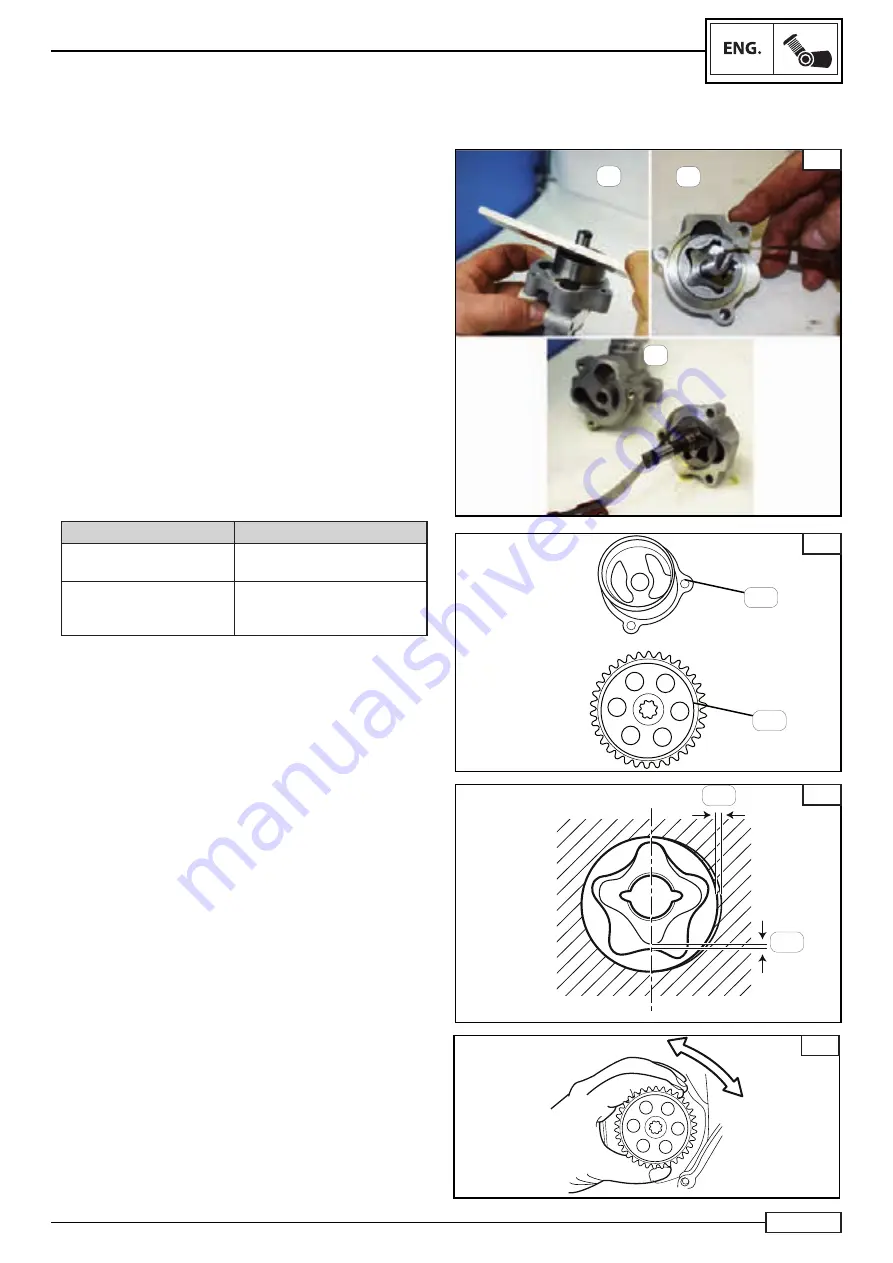

Remove:

•

the screws (9*)

•

the pump cover (6*)

•

outer rotor (10*)

•

inner rotor (11*)

• roller

(8*)

•

oil pump shaft (7*)

Check:

•

the pump body (13*) Fig. D

If there are any lines/damage/wear, replace.

•

The pump pinion (5*)

If there is any damage or wear to the gears, replace.

Measure:

•

the tolerance between the inner rotor (11*) and the outer

rotor (10*) ”C”. Fig. E and Fig. C (A)

•

the tolerance between the outer rotor (11*) and the oil pump

housing (6*) ”E”. Fig. E and Fig. C (B)

• the

fl atness of both rotors compare to the oil pump housing

(6*) “C” Fig. C.

Clearance

Tolerance

between the inner rotor

and the outer rotor ”

A”.

0.15 mm

between the outer rotor

and the oil pump housing

“

B

”

+0.06, +0.09 mm

Check:

•

oil pump operation.

Turn the pump pinion (5*) as shown in Fig. F

If the movement is not smooth, check the inner/outer rotor seat.

If there are any lines/damage, replace the

faulty part/s.

NOTE:_________________________________

This check is carried out after securing the oil pump in the

engine body and inserting the pump pinion (5*) in its seat.

NOTE:_________________________________

Numbers marked (*) are part of the spare parts table in

Chapter 5 “Lubrication circuit”.

D

E

F

13*

5*

C

D

COPY - Moto GB - Grant Martland - grantmartland@motogb.co.uk

Summary of Contents for TRK 502

Page 6: ...1 1 1 COPY Moto GB Grant Martland grantmartland motogb co uk ...

Page 19: ...2 2 1 COPY Moto GB Grant Martland grantmartland motogb co uk ...

Page 37: ...3 1 3 COPY Moto GB Grant Martland grantmartland motogb co uk ...

Page 40: ...3 4 NOTES COPY Moto GB Grant Martland grantmartland motogb co uk ...

Page 95: ...4 1 4 COPY Moto GB Grant Martland grantmartland motogb co uk ...

Page 254: ...5 1 5 COPY Moto GB Grant Martland grantmartland motogb co uk ...

Page 345: ...6 1 6 COPY Moto GB Grant Martland grantmartland motogb co uk ...

Page 360: ...ELE 16 7 COPY Moto GB Grant Martland grantmartland motogb co uk ...