Summary of Contents for SWIFT TRAWLER 42

Page 1: ...SWIFT TRAWLER 42 Code 087851 Index C Owner s Manual ...

Page 2: ......

Page 4: ......

Page 7: ...3 Introduction HISTORY OF UPDATES Index A 10 2008 Index B 01 2010 Index C 09 2010 ...

Page 8: ......

Page 10: ......

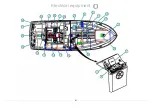

Page 11: ...7 General specifications Technical specifications Certification Design category Your boat 1 ...

Page 16: ......

Page 26: ......

Page 30: ...26 USE OF THE MANUAL BILGE PUMP Location Operation Capacity 40 5 litre minute Safety ...

Page 34: ......

Page 35: ...31 Hull Maintenance of the Hull Lifting 3 ...

Page 36: ...32 LIFTING Wetted area 48 m Hull ...

Page 38: ......

Page 46: ......

Page 48: ......

Page 49: ...45 Steering system Steering Gear 5 ...

Page 52: ...48 ACCESS TO ELEMENTS ENGINE COMPARTMENT Steering pump Steering components Steering system ...

Page 53: ...49 Interior Introduction Interior maintenance Maintenance of fabrics 6 ...

Page 54: ...50 INTRODUCTION Interior ...

Page 58: ......

Page 63: ......

Page 67: ......

Page 69: ......

Page 75: ......

Page 79: ...75 Water and sewage water 7 ...

Page 80: ......

Page 82: ......

Page 84: ...80 MAIN ELEMENTS SCHEMATIC DIAGRAM ELECTRICAL CIRCUIT 12 V Electrical equipment ...

Page 85: ...81 Electrical equipment 8 ...

Page 89: ......

Page 91: ......

Page 98: ...94 LEAD LINES Transducer location View interior View Outside Electrical equipment ...

Page 106: ......

Page 107: ...103 Engine General information Engine installation 9 ...

Page 108: ......

Page 110: ...106 Fuel filler Starboard gangway position Tank interconnecting valve Engine ...

Page 112: ...108 1 1 2 3 4 5 6 7 8 9 10 Engine ...

Page 114: ......

Page 116: ......

Page 122: ......

Page 124: ......

Page 125: ...121 Launching Launching recommendations 10 10 ...

Page 126: ...122 POSITION OF HOISTING CRADLE AND STRAPS Note Measurements are expressed in mm Launching ...

Page 128: ......

Page 129: ...125 Winter Storage Laying up Protection and maintenance 11 11 ...

Page 130: ......