26

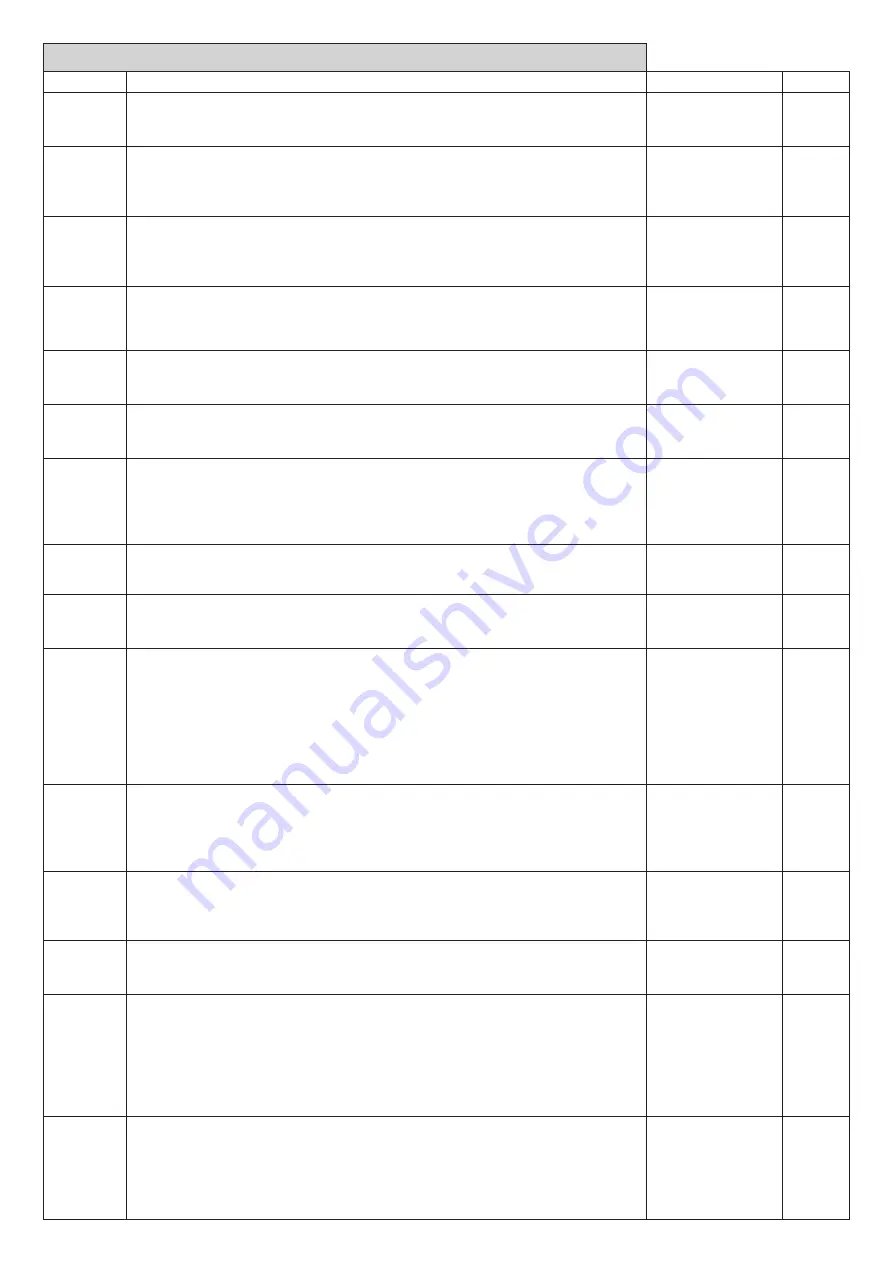

8.4.2) LOGICS (

LOG

)

MENU

FUNZIONE

ON-OFF-(Default)

MEMO

TCA

Enables or disables automatic closing

On: automatic closing enabled

Off: automatic closing disabled

(ON)

IbL

Enables or disables condominium function.

On: condominium function enabled. The step-by-step impulse or transmitter impulse has no

effect during the opening phase.

Off: condominium function disabled.

(OFF)

ibca

The multi-flat function is enabled or disabled during the TCA counting.

On: the bloc of flat function is enabled. The Step-by-Step signal or the transmitter signal has no

effect during the TCA counting.

Off: the bloc of flat function is disabled.

(OFF)

SCL

The rapid closure is enabled or disabled

On: rapid closure is enabled. When the gate is open or moving, the photocell activation causes

the automatic closure of the gate after 3 s. It is activated only with

TCA

:ON

Off: rapid closure is disabled.

(OFF)

PP

Selects the operating mode of the ”Step by step button” and of the transmitter.

On: Operation: OPEN > CLOSE > OPEN >

Off: Operation: OPEN > STOP > CLOSE > STOP >

(OFF)

PRE

Enables or disables pre-blinking.

On: Pre-blinking enabled. Blinking is activated 3s before the motor starts.

Off: Pre-blinking disabled.

(OFF)

htr

Enabled or disables HOLD-TO-RUN function

On: HOLD-TO-RUN function.

The pressure of the OPENS/CLOSES button must be maintained throughout the entire manoeuvre.

The opening of the STOP input stops the motor. All the safety inputs are deactivated.

Off: Automatic/semiautomatic function

(OFF)

opcl

PP input as OPEN and PED input as CLOSED are enabled or disabled.

On: PP input is enabled as OPEN and PED input is enabled as CLOSE.

Off: PP and PED inputs are enabled with their function.

(OFF)

ltca

Selects the operating mode of the blinking light during the time TCA

On: Blinking light on during TCA

Off: Blinking light off during TCA

(OFF)

phcl

The operating mode of the PHOT C input is selected.

On: PHOT C input is activated in both opening and closing phases.

In the opening phase: the contact opening causes the motor stop. When the photocell is

released, the motor restarts in the opening phase.

In closing phase: the contact opening causes the motor stop. When the photocell is released,

the motor inverts the movement direction (open).

Off: The PHOT C input is activated in the closing phase only.

In the closing phase: the contact opening causes the motor stop and the immediate reversion

of the operation direction (open).

(OFF)

TST1

Enables or disables checking of photocells on PHOT input, active both in closing and in opening.

On: Check enabled. If the check has a negative result, no manoeuvre is commanded. See

Fig.167- “PHOTO TEST”. (AUX1=3)

Off: Check of photocells each time a manoeuvre is disabled. This setting requires maintenance

of photocells every 6 months.

(OFF)

tst2

Enables or disables the check of photocells on PHOT C input.

On: Check enabled. If the check fails, no manoeuvre will be enabled. (AUX1=3)

Off: Check of photocells each time a manoeuvre is disabled. This setting requires maintenance

of photocells every 6 months.

(OFF)

TSTm

Enables or disables motors check.

On: Check enabled. If the check has a negative result, no manoeuvre is commanded.

Off: Check disabled.

(OFF)

bar

Changing the operating mode of the PHOT OPEN and BAR inputs in the event the sensitive

edges are installed on the mobile opening and closure edges (see Fig.21).

On: The PHOT OPEN input assumes a similar function to the BAR input, but inverts motion for

3s only during the opening phase. The edge connected to the BAR input is only active during

the closure phase.

Off: Intervention of the sensitive edge connected to the BAR input stops movement of the door

and inverts for approx. 3s, both opening and closure.

The PHOT OPEN input re-starts functioning of the photocell active on opening.

(OFF)

aopf

The “forced opening in case of power cut-off” function is activated or deactivated (it can be

activated only with connected and operating emergency batteries).

On: Activated function. In the event of power failure, before the emergency battery completely

discharged, the control unit causes an opening operation.

The barrier remains open until the power supply is back.

Off: Deactivated function.

(OFF)

Summary of Contents for BULL 1524

Page 2: ...2 A B 1 200 245 316 340 300 215 340 34mm BULL PI Optional 40 3 1 8 2 0 4 7 0 1 8 0 2 3 ...

Page 3: ...3 V Z R 4 7 B F T MIN 10 mm MAX 20 mm MIN 120 mm MAX 140 mm 5 6 R D R D ...

Page 5: ...5 12 13 14 C L 7 4 1 2 3 POWER 2 x 1 5 RG 58 5 4 x 0 25 4 6 5 2 x 0 25 3 x 0 25 15 ...

Page 9: ...9 22 DA BT6 ...