16

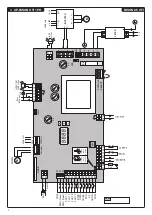

Fuse

Type

Description

F1

250V T1A

Protection, power supply of accessories

F2

250V T400mA

Protection, logics of board

F3

250V T630mA

Protection, common inputs and serial of inverter

F4

500V T125mA

Protection, transformer primary

F5

250V T500mA

Protection, lashing light, 230V

HOW TO CHECK CONNECTIONS

1) Cut off power supply.

2) Manually release the door/gate and push it for about half stoke. Lock the door again.

3) Restore power supply.

4) Send a step-by-step command through push-button <->* on the control unit (LCD display off). To stop the door/gate press <->* once

more.

5) The door/gate should open. If not, use the MINV logics to change the opening direction.

* Bison 25: <+>

INVERTER

The CP.BISON OTI control unit is provided with serial connections for the control of a pre-installed inverter on the gear motors of the

BISON series.

The inverter allows to enhance the functional performance of the motor as regards control of the torque, speed and safety.

Although the pre-installed inverter is provided with programming functions, none of them must be changed by the installer because the

CP.BISON control unit directly controls all the operating parameters. If the device is to be replaced, ask an original spare part to the

manufacturer and carry out its wiring in compliance with connections shown in the handbook supplied with the spare part itself. Do not

use inverters which are not supplied by the manufacturer for any reason whatsoever.

PROGRAMMING

The programming of the various functions of the control unit is carried out using the LCD display on the control unit and setting the

desired values in the programming menus described below.

The parameters menu allows you to assign a numerical value to a function, in the same way as a regulating trimmer.

The logic menu allows you to activate or deactivate a function, in the same way as setting a dip-switch.

Other special functions follow the parameters and logic menus and may vary depending on the type of control unit or the software

release.

TO ACCESS PROGRAMMING

1 – Press the button <OK>, the display goes to the first menu, Parameters “PAR”.

2 – With the <+> or <-> button, select the menu you want.

3 – Press the button <OK>, the display shows the first function available on the menu.

4 – With the <+> or <-> button, select the function you want.

5 – Press the button <OK>, the display shows the value currently set for the function selected.

6 – With the <+> or <-> button, select the value you intend to assign to the function.

7 – Press the button <OK>, the display shows the signal “PRG” which indicates that programming has been completed.

NOTES

Pressing <-> with the display turned off means an impulse of P.P.

Simultaneously pressing <+> and <-> from inside a function menu allows you to return to the previous menu without making any

changes.

Hold down the <+> key or the <-> key to accelerate the increase/decrease of the values.

After waiting 30s the control unit quits programming mode and switches off the display.