9

1) CONTROL PANEL CP.BULL5 ARC

ARC TRANSMITTERS

IMPORTANT, PLEASE READ CAREFULLY:

The radio receiver in this product is compatible only with ARC (Advanced Rolling Code) transmitters which, thanks to 128 bit

coding, guarantee superior anti-copying security.

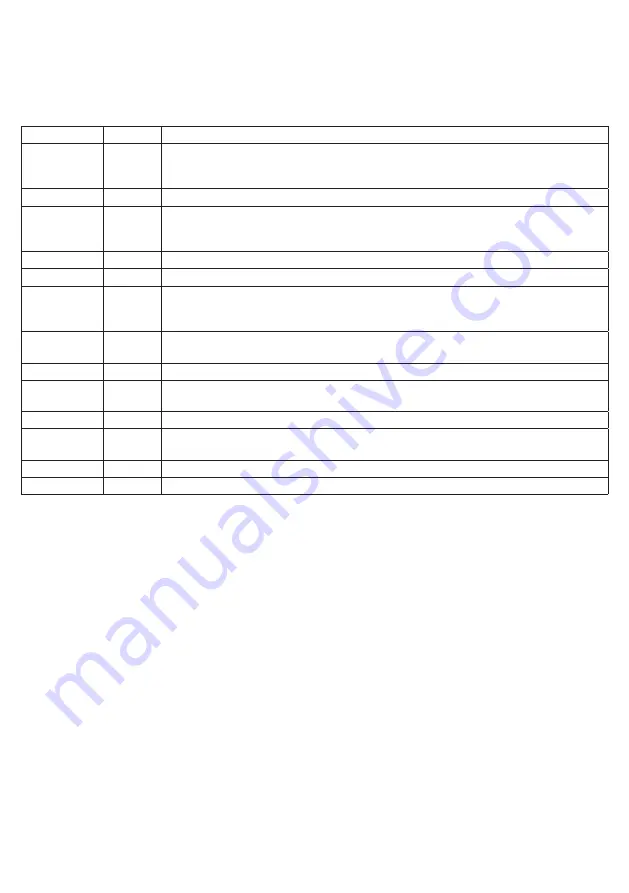

1.1) WIRE DIAGRAM

Wire connections shown in Fig. 1 are described hereunder:

Terminals

Function

Description

L-N-GND

Power

supply

Input, 230VAC 50Hz (CP.BULL5 ARC)

Input, 115VAC 50/60Hz (CP.BULL5 ARC 115V))

(1-Phase/2-Neutral/GND-Ground connection)

MOT-COM-MOT Motor

Connection to motor: (MOT-move/COM-Common/MOT-move)

N-BLINK

LAMP

Output, connection to Flashing light

CP.BULL5 ARC: 230 Vac 40W max.

CP.BULL5 ARC 115V: 115 Vac 40W max.

SWO

SWO

Input, OPENING limit switch (Normally Closed contact)

SWC

SWC

Input, CLOSING limit switch (Normally Closed contact)

PHOT (CLOSE)

PHOT

Input, connection to safety devices, Normally Closed (N.C.) contact (e.g. photocells): configurable through DIP3).

In “Service man” mode, it activates the CLOSE function.

In this case connect a Normally Open (N.O.) key.

STOP

STOP

Input, STOP key (N.C. contact)

Can assume the Close or Pedestrian function (contact N.O.) see “Advanced Programming” paragraph.

COM

COM

Common, all control inputs.

P.P. (OPEN)

Step

by-Step

Input, step-by-step key (N.O. contact). Can assume the OPEN function see paragraph “Advanced Programming”.

In “Service man” mode, it activates the OPEN control function.

24 VAC

24Vac

Output, 24Vac/200mA max accessory power supply.

SCA

SCA

Contact free from voltage, not insulated for the connection of open gate indicator lamp. Open contact with

closed door leaf. Flashing light during the door leaf movement. With open door leaf, the contact is closed.

ENC1

ENCODER

Input, connection of the encoder (OPTIONAL). See section 5

SHIELD-ANT

Antenna

Connection of the antenna to the incorporated radio-receiver module (SHIELD-screen/ANT-signal).

Note: The control unit uses a “P2” key with the same functions of the Step-by-Step push-button. This is useful to control the automatic

system during installation (only with DIP2: OFF).

2) CHECKING CONNECTIONS

1) Cut off power supply.

2) Manually release the door, move it at around half stroke and lock it again.

3) Reset power supply.

4) Send the step-by-step (P.P.) control signal through the P2 key, P.P. or remote control.

5) The door leaves should open. If not, with stopped motor, it is sufficient to invert the move wires of the motor (MOT/MOT) of the

motor and the limit switches (SWO/SWC).

6) Proceed with regulations described in “STROKE ACQUISITION & SLOWDOWNS”

3) TRIMMER FUNCTIONS

3.1) TW - If the Encoder device is installed, it assumes the function of regulating anti-crushing sensitivity. When turned in a clockwise

direction, sensitivity is increased.

In the absence of an Encoder device, regulate the maximum duration of opening and closing manoeuvres. It must be preset approx. 4s

more with respect to the actual stroke time of the system. The adjustment ranges from 3s to 180s maximum. If the stroke acquisition

and slowdowns procedure is executed, the position of the trimmer has no effect on the operation time.

3.2) TCA -

It allows to adjust the automatic closure time.The adjustment ranges from 3s to 180s maximum.

With TCA trimmer completely turned clockwise, the DL2 LED (green) switches off, TCA is deactivated.