14

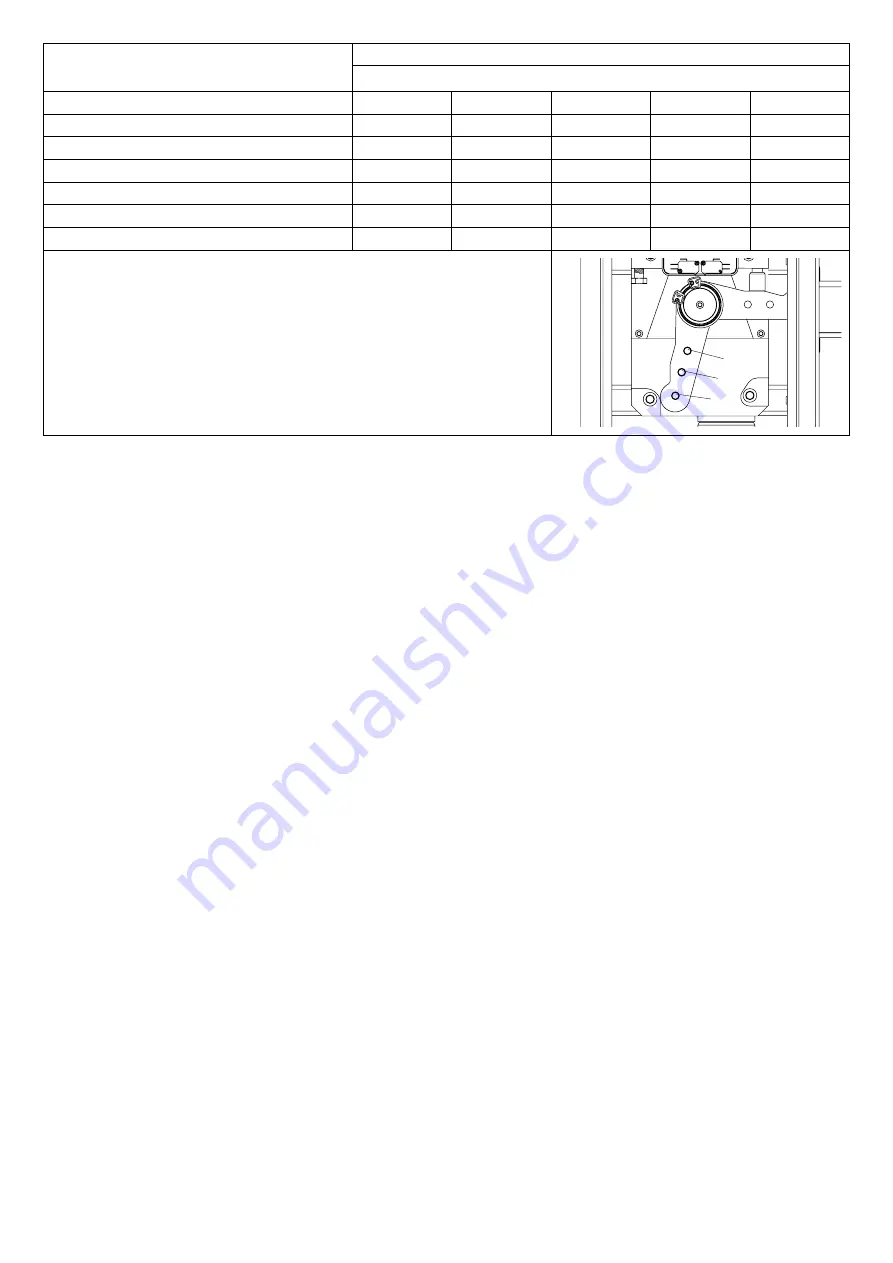

PoSItIonIng oF tHE SPrIng

AnD ACCESSorIES

FIg.6

According to the length of the beam and the type of accesso-

ries installed, before tensioning the spring, the correct point

to hook the spring to the lever must be selected.

The correct hooking point (“A”, “B” and “C”), must be se-

lected by taking account of table 1, according to the beam

length and the type of accessories to be installed.

HoW to FIX tHE BEAM

FIg.7

Any accessories for the beam (protection edges, lights, pneu-

matic safety edges, rack, etc. ) are installed before fitting the

beam. See relevant instructions.

Fit the beam to plate P by using bracket S and both the 6

screws with the corresponding washers, and plate T.

Apply the removable plastic cover C.

EMErgEnCY MAnuAL oPErAtIon

FIg.8

Should a power failure occur or in the event of faults in the

system, the beam can be released and moved by hand:

• Introduce the customized key in the release lever and turn

it clockwise.

• Turn the release lever anti-clockwise until the beam is

released and it can be opened and closed by hand.

• To reset the automatic operation, turn the lever clockwise

until the beam is released. Reset the initial position.

BALAnCIng

FIg.9

For a good operation of the road barrier, the beam must be

suitably balanced by the spring.

To check the correct balancing, proceed as follows.

• Check that the spring is correctly hooked to the lever (see

table 1).

• Mechanically release the road barrier through the release

key.

• The road beam, correctly balanced, should remain still in

tAB.1

EVA.5

Bar length (m)

Accessories for use

3

3,5

4

4,5

5

EVA5.A

C

C

B

B

A

EVA5.A + VE.RAST

C

B

B

A

A

EVA5.A + VE.AM

C

C

B

B

A

EVA5.A + VE.RAST + VE.AM

C

B

B

A

A

EVA5.A + SC.RES

C

B

B

A

A

EVA5.A + SC.RES + VE.AM

C

B

B

A

A

Key

EVA5.A

Shank with rubber and upper profile.

VE.rASt

Aluminium skirt.

VE.AM

Mobile support for bar.

SC.rES

Sensitive resistive edge (complying with annexe 4

of the Machines Directive).

Attention:

The installation of the

VE.rASt

interferes with the use of the

SC.rES

and vice

versa.

The installation of the

EVA.L

lights kit does not influence the balancing of the bar

any position:

- if it tends to open, reduce the spring tension

- if it tends to close, increase the spring tension

The spring tension can be adjusted by tightening (anti-

clockwise rotation) or loosening (clockwise rotation) the

spring by hand. Once the spring tension is adjusted, lock

it by moving the nut “D” in contact with cap T.

MoVEMEntS AnD oPErAtIng tIME

During opening as per Fig. 10:

Starting from the closing position “C”, the beam starts its

opening until it reaches the “SWO-R” point, where the ope-

ning limit switch triggers. The opening speed can be adjusted

through the control unit.

The beam moves for the remaining space (as shown in Fig.10)

at a reduced speed, for a time preset by the control unit.

Therefore, the barrier reaches point A, by completing the

opening movement.

During closure, as per Fig. 11:

The beam starts moving from the opening point “A” and stops

at “SWC-R “ point, when the braking limit switch triggers. The

closing speed can be preset through the control unit.

After activation of the braking limit switch, the braking cycle

starts, ending only when the closing limit switch “C” trig-

gers.

The control unit checks the activation of the “SWC” limit

switch and it is able to automatically offset any changes due

to different weather conditions, for example.

The braking angle shown in Fig.11 is fixed at around 25°.

Adjustments of the limit switch cams, trimmers and dip-

switches should be carried out by referring to these operating

principles.

ADJuStMEnt oF LIMIt SWItCH CAMS

FIg.13

The adjustment of the limit switch cams allow for the fol-

lowing:

Cam o

To advance or delay the starting of braking in the opening

C

B

A

Summary of Contents for EVA 5

Page 2: ...2 1 A A 3 D 2 EVA 5 SX EVA 5 DX 320 330 235 1200 Min 2 75m Max 4 75m 250...

Page 3: ...3 4 F1 F2 F1 F2 L L...

Page 5: ...5 8 9 D T CLACK...

Page 6: ...6 10 12 11 SWO R A C A SWC R C SWC SWO R SWC R SWC O C V...

Page 7: ...7 13 G 14 F1 F2 2 9x16 FTC S 3 1 2 4 4 5 6 7 3x1 5mm 2x1mm...

Page 40: ...AUTOMATISMI BENINC SpA Via Capitello 45 36066 Sandrigo VI Tel 0444 751030 r a Fax 0444 759728...