14

see section “Balancing”.

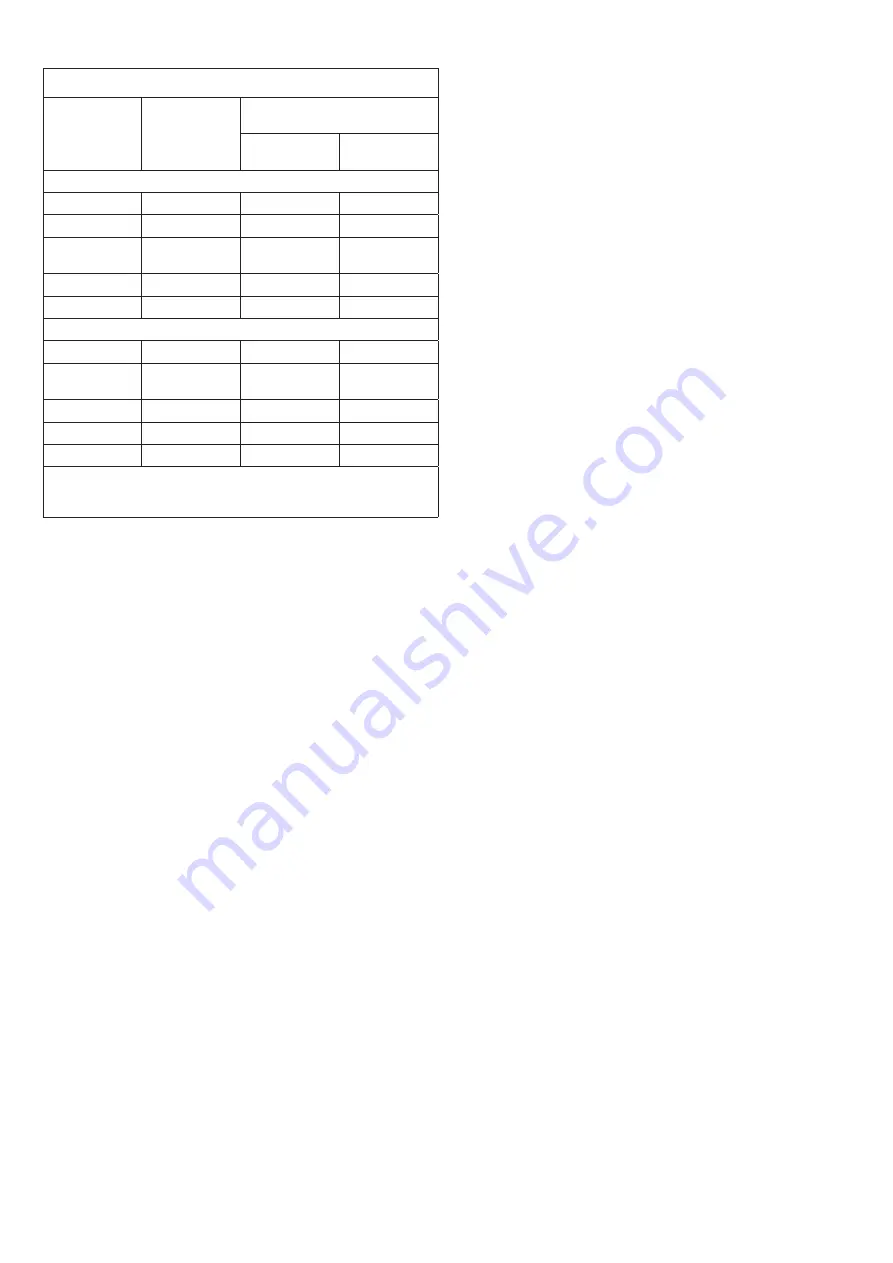

TABLE 1

BEAM

LENGTH (m)

SPRINGS TO

BE USED

INDICATIVE TENSIONING

(mm)

SPRING

364mm

SPRING

480mm

WITHOUT ACCESSORIES

5

1 spring, 480

35

5,5

1 spring, 480

90

6

1 spring, 364

1 spring, 480

31

15

6,5

2 springs, 480

5/5

7

2 springs, 480

35/35

WITH ACCESSORIES*

5

1 spring, 480

100

5,5

1 spring, 364

1 spring, 480

52

138

6

2 springs, 480

20/20

6,5

2 springs, 480

65/65

7

**

* One or more of these accessories: upper cover, flashing lights EVA.L,

SC.RES, VE.RAST, VE.AM.

** A 7 m long beam can be used only without accessories.

HOW TO FIX THE BEAM

FIG.6

Any accessories for the beam (protection edges, lights, pneu-

matic safety edges, rack, etc. ) are installed before fitting the

beam. See relevant instructions.

Fit the beam to plate P by using bracket S and both the 6

screws with the corresponding washers, and plate T.

Apply the removable plastic cover C.

PREPARATION OF A RIGHT-HAND OR

LEFT-HAND ROAD BARRIER

FIG.7-8

If it is necessary to modify the opening direction of the road

barrier from right-hand to left-hand, or viceversa, proceed

as follows:

• totally unload the springs by loosening them and unhook

them from the anchoring lever “L” (fig. 8)

• remove screws D1 and D2 and fix the extension rod A in

the opposite position, on lever V.

• remove and fix the extension lever R in the opposite po-

sition.

• fix the springs onto the anchoring lever “L” .

• Fig. 8 shows the different positions of the components

shows the differences between a right-hand road barrier

and a left-hand one.

• in the control unit, invert the wires of motor, as well

as SWC limit switch (closing limit switch) and SWC-R

limit switch (closure braking limit switch).

EMERGENCY MANUAL OPERATION

FIG.9

Should a power failure occur or in the event of faults in the

system, the beam can be released and moved by hand:

• Introduce the customized key in the release lever and turn

it clockwise.

• Turn the release lever clockwise until the beam is released

and it can be opened and closed by hand.

• To reset the automatic operation, turn the lever anti-

clockwise until the beam is released. Reset the initial

position.

BALANCING

FIG.10

For a good operation of the road barrier, the beam must be

suitably balanced by the spring.

To check the correct balancing, proceed as follows:

• Mechanically release the road barrier through the release

key.

• The road beam, correctly balanced at approx. 45° , should

remain still in any position:

- if it tends to open, reduce the spring tension

- if it tends to close, increase the spring tension

The spring tension can be adjusted by tightening (anti-

clockwise rotation) or loosening (clockwise rotation) the

spring by hand. Once the spring tension is adjusted, lock

it by moving the nut “D” in contact with cap T.

• In table 1 of the “indicative tensioning” column, mea-

sures (expressed in millimeters) are shown. To obtain a

tensioning value near to optimal, these measures must

be added to the spring length in rest position.

For example:

In the event of a road beam 5.5m long, with installed ac-

cessories, the 364mm spring should be tensioned until

a length of 416mm (364+52), while the 480mm spring

should be tensioned at a length of 618mm (480+138).

When two 480mm springs are used, the tensioning value

of the two springs must be the same.

MOVEMENTS AND OPERATING TIME

During opening as per Fig. 11:

Starting from the closing position “C”, the beam starts its

opening until it reaches the “SWO-R” point, where the ope-

ning limit switch triggers. The opening speed can be adjusted

through the control unit.

The beam moves for the remaining space (as shown in Fig.11)

at a reduced speed, for a time preset by the control unit.

Therefore, the barrier reaches point A, by completing the

opening movement.

During closure, as per Fig. 12:

The beam starts moving from the opening point “A” and stops

at “SWC-R “ point, when the braking limit switch triggers. The

closing speed can be preset through the control unit.

After activation of the braking limit switch, the braking cycle

starts, ending only when the closing limit switch “C” trig-

gers.

The control unit checks the activation of the “SWC” limit

switch and it is able to automatically offset any changes due

to different weather conditions, for example.

The braking angle shown in Fig.12 is fixed at around 25°.

Adjustments of the limit switch cams, trimmers and dip-

switches should be carried out by referring to these operating

principles.

ADJUSTMENT OF LIMIT SWITCH CAMS

FIG.13

The adjustment of the limit switch cams allow for the fol-

lowing:

Cam O

To advance or delay the starting of braking in the opening

phase (Fig.12 - “SWO-R” point).

Cam C

Summary of Contents for EVA.7

Page 2: ...2 1 375 300 260 460 1265 Min 4 70m Max 6 70m 3 D 2 EVA7 SX EVA7 DX...

Page 4: ...4 7 8 D1 R D2 A V L L...

Page 5: ...5 9 10 CL CLACK D T...

Page 6: ...6 11 13 12 SWO R A C A SWC R C SWC SWC R O C SWC...

Page 7: ...7 14 15 3 1 2 4 4 5 6 7 3x1 5mm 2x1mm F2 F1 V2 V1...

Page 40: ...AUTOMATISMI BENINC SpA Via Capitello 45 36066 Sandrigo VI Tel 0444 751030 r a Fax 0444 759728...