24

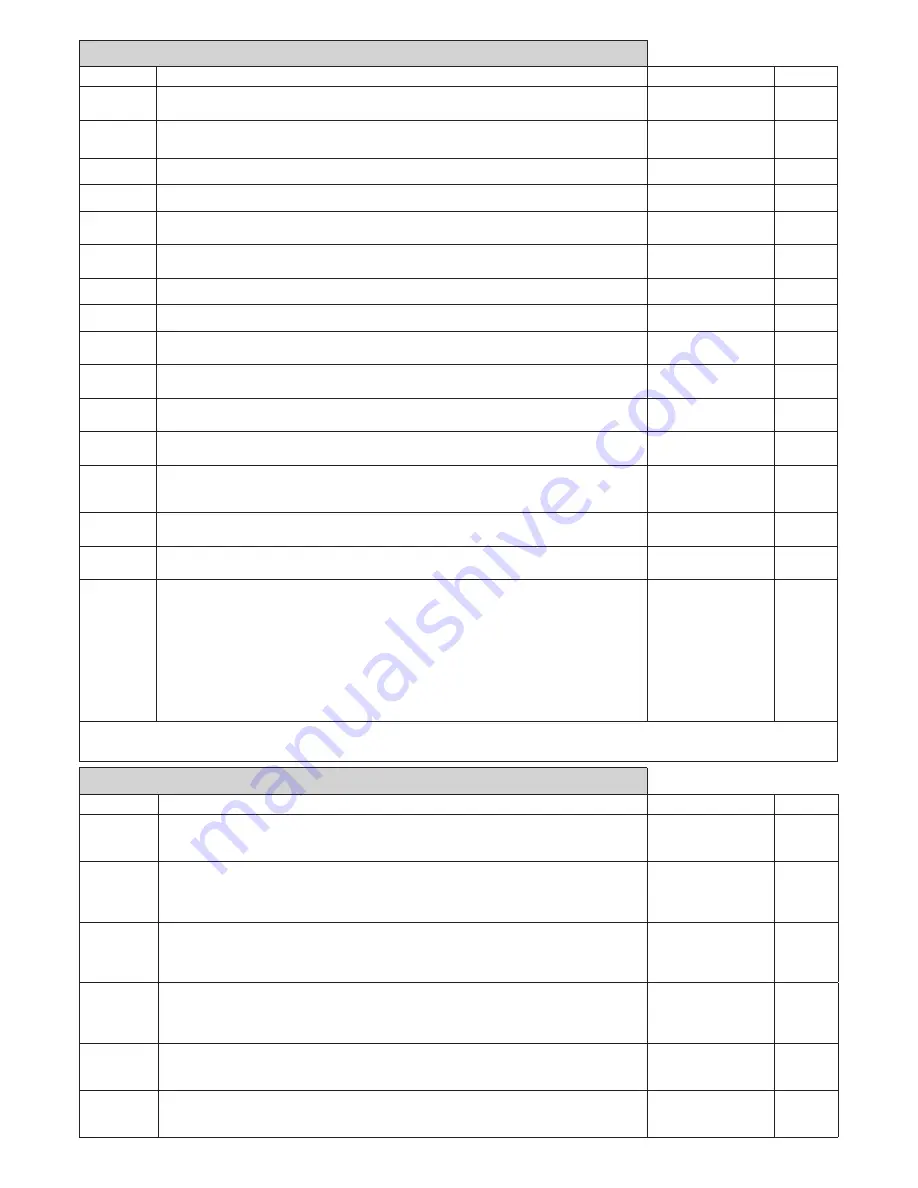

13.3.2) PARAMETERS (

PAR

)

MENU

FUNCTION

MIN-MAX-(Default)

MEMO

TCA

Automatic closing time. Enabled only with logic “TCA”=ON.

At the end of the set time, the control unit commands a closing maneuver .

1-240-(20s)

FSTS

Adjusts the opening and closing speed of the barrier (standard speed, before the slowdown

phase).

50-99-(99)

sldo

Adjusts the slowdown speed of the barrier during the opening phase* (Fig.11 -slow Open).

20-70-(50)

sldc

Adjusts the slowdown speed of the barrier during the closing phase * (Fig.12 -slow Close).

20-70-(50)

tsmo

Sets the starting point of the slowdown during the opening phase (Fig.11- beginning of the slow

Open). The value is expressed in percentage on the entire stroke.

1-99-(20)

tsmc

Sets the starting point of the slowdown during the closing phase (Fig.12- beginning of the slow

Close). The value is expressed in percentage on the entire stroke.

1-99-(20)

PMO

Adjusts the motor torque applied to the barrier during the opening phase.*

1-99-(20)

PMC

Adjusts the motor torque applied to the barrier during the closing phase.*

1-99-(20)

PSO

Adjusts the motor torque applied to the barrier during the slowdown in opening phase * (Fig.10

- Slow Open).

1-99-(20)

PSC

Adjusts the motor torque applied to the barrier during the slowdown in closing phase * (Fig.11

- Slow Close).

1-99-(20)

SeaU

Adjusts the intervention threshold of the anti crushing device (Encoder) during the normal speed*.

0:Off -1: minimum sensitivity - 99: maximum sensitivity

0-99-(0%)

SEAR

Adjusts the intervention threshold of the anti crushing device (Encoder) during the slowdown speed*.

0:Off -1: minimum sensitivity - 99: maximum sensitivity

0-99-(0%)

tls

Activation time of the courtesy light contact. Value expressed in seconds. At the beginning of

each maneuver the contact latches for the set time.

See the description of AUX1 parameter.

1-240 (60)

saso

Sets a short reversion after reaching the limit switch in open position. Can be useful for facilitat-

ing the manual release.

0-5 (0)

sasc

Sets a short reversion after reaching the limit switch in close position. Can be useful for facilitat-

ing the manual release.

0-5 (0)

aux1

Selects the functioning mode of the auxiliary output 1 (N.O. clean contact)

0: Open barrier light, close contact when the barrier is open, open contact when the barrier is

close, intermittent during the maneuver (fig. 14, SCA)

1: Second radio cannel of the built in receiver

2: Boom light, for controlling the LED light installed on the BOOM (EVA.LED), see also the pa-

rameter LBAR.

3: Courtesy light, the contact remains close according to the parameter TLS (fig.14 SERVICE LIGHT)

4: Photocells test, see wiring diagram in Fig.14 (PHOTOTEST)

5: Close contact with open barrier

6: Close contact with close barrier

0-6-(0)

* ATTENTION: A WRONG SETTING OF THESE PARAMETERS CAN BE DANGEROUS.

RESPECT THE REGULATION IN FORCE!

13.3.3) LOGICS (

LOG

)

MENU

FUNZIONE

ON-OFF-(Default)

MEMO

TCA

Enables or disables automatic closing

On: automatic closing enabled

Off: automatic closing disabled

(ON)

IbL

Enables or disables condominium function.

On: condominium function enabled. The step-by-step impulse or transmitter impulse has no

effect during the opening phase.

Off: condominium function disabled.

(OFF)

ibca

The multi-flat function is enabled or disabled during the TCA counting.

On: the bloc of flat function is enabled. The Step-by-Step signal or the transmitter signal has no

effect during the TCA counting.

Off: the bloc of flat function is disabled.

(OFF)

SCL

Enables or disables rapid closing

On: rapid closure is enabled. With open bar, or in the opening phase, the activation of the photocell

causes the automatic closure 3sec after the total opening of the gate. It is activated only with TCA:ON

Off: rapid closing disabled.

(OFF)

PP

Selects the operating mode of the ”Step by step button” and of the transmitter.

On: Operation: OPEN > CLOSE > OPEN >

Off: Operation: OPEN > STOP > CLOSE > STOP >

(OFF)

PRE

Enables or disables pre-blinking.

On: Pre-blinking enabled. Blinking is activated 3s before the motor starts.

Off: Pre-blinking disabled.

(OFF)