27

EN

13.5) TRANSMITTERS REMOTE LEARNING

If an already memorised transmitter is available in the receiver it is possible to carry out remote radio learning (without needing to access the control unit).

IMPORTANT: the procedure must be carried out with barrier open.The logic REM must be ON.

Proceed as follows:

1 Press the hidden key of the transmitter which is already memorised.

2 Press, within 5s, the key of the corresponding transmitter which is already memorised to associate to the new transmitter. The flashing light will turn on.

3 Press within 10s the hidden key of the new transmitter.

4 Press, within 5s, the key of the new transmitter to associate to the channel chosen at point 2. The flashing light will turn off.

5 The receiver memorised the new transmitter and immediately exits from programming.

13.6) FUSES

F3 CP.EVA2: T1A - Fuse for the protection of the accessories power supply

F1 SA.24V: T4A - Fuse for general protection

13.7) BACK UP BATTERIES

The control unit CP.EVA2 includes the power pack SA.24V predisposed for the connection of two batteries by 12Vdc 2,1Ah DA.BT2 (optional) which

guarantee the regular functioning of the automation in case of temporary power failure.

When the barrier is working with mains voltage the power pack SA.24V charges the batteries (Fig. 13).

The maximum charging current is 1A, the average charging current is 300 mA.

13.8) DIAGNOSTICS

PHOT

SW Close

STOP

SW Open

P.P.

OPEN CLOSE

LED 1 : Presence of mains voltage

LED 2 : Control unit CP.EVA2 correctly powered

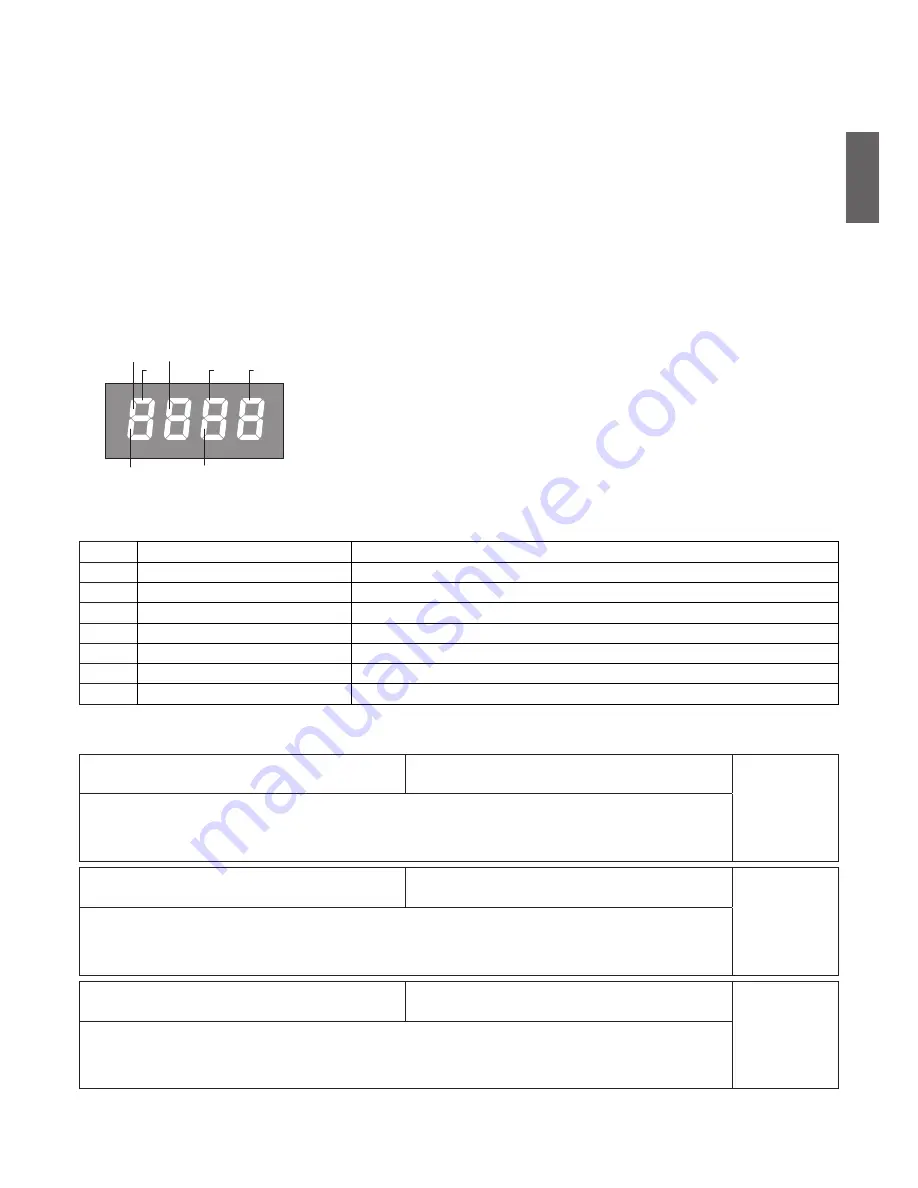

To each input is associated a line of the LCD screen which in case of activation it turns on according to

the following diagram.

The N.C. inputs are represented by vertical lines.

The N.O. inputs are represented by horizontal lines.

The flashing mode of the lines SW Open (when the barrier is open) and SW Close (when the barrier is

close) indicates the type of limit switch used.

2 flashes and pause: Presence of mechanical stops, no encoder, no electromechanical limit switches

1 flash and pause: Absolute encoder version (standard)

No flashing (always on) = Electromechanical limit switches

13.9) ERROR MESSAGES

Some messages that are displayed in case of function anomalies are listed as follows:

Err

Generic error

Error inserting password or memorizing transmitter..

Err1

Motor error

Verify the motor wirings, faulty motor or not connected, problem on the control unit.

Err2

Photocells error

Verify connections, photocells alignment and presence of obstacles.

err3

Absolute encoder error

Verify encoder connections, verify the good functioning of the Encoder.

AMP

Amperometric sensor intervention

Verify the presence of obstacles or friction points.

THRM

Thermal sensor intervention

Overheating due to a too intensive use, wait the restoring.

OVLD

Overload

Exceeding of the maximum power. Verify the motor and presence of friction points..

Enc

Encoder

Encoder threshold intervention.

14) MAINTENANCE

The following table is used to record maintenance operations, improvement or repair works carried out by the expert engineer.

Date _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Engineer's Signature _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Stamp

Description of operation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Date _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Engineer's Signature _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Stamp

Description of operation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Date _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Engineer's Signature _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Stamp

Description of operation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _