22

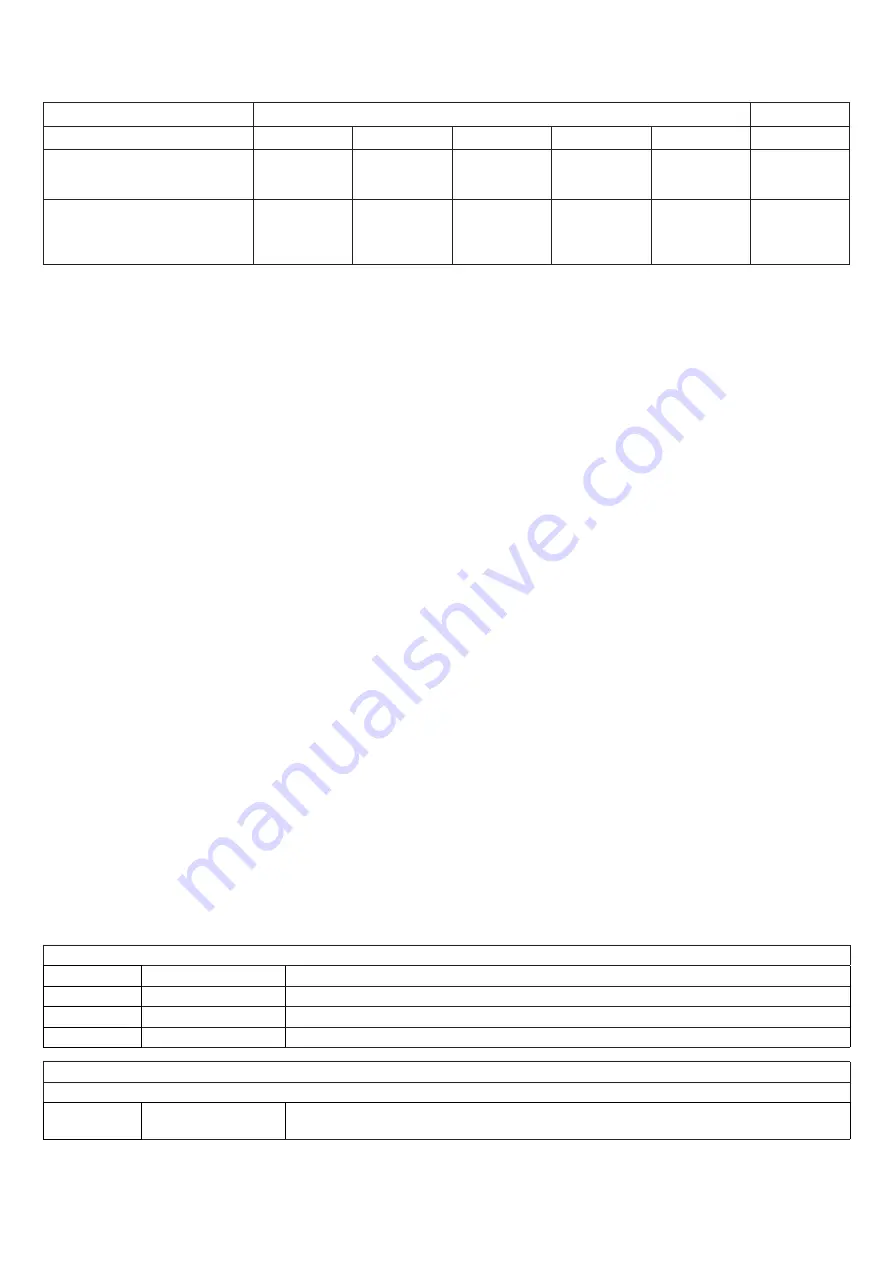

7) SELECTION OF SPRING AND THE ACCESSORIES FOR USE

Based on the length of the shaft and the type of accessories installed, before proceeding to tensioning the spring, the correct type of springs must be

chosen.

VE.650

Length of the rod (m)

4,5

5,0

5,5

6,0

6,0

6,5

Type of spring

1 neutral

1 yellow

+

1 neutral

1 yellow

+

1 neutral

1 yellow

+

1 neutral

2 neutral

2 neutral

Usable accessories

VE.AM

SC.RES

VE.L650

VE.RAST

VE.AM

SC.RES

VE.L650

VE.RAST

VE.AM

SC.RES

VE.L650

VE.RAST

---------

---------

---------

---------

VE.AM

SC.RES

VE.L650

VE.RAST

VE.AM

SC.RES

VE.L650

VE.RAST

Key

VE.AM

Mobile rest for arm

SC.RES

Sensitive edge of the resistive type (in compliance with attachment 4 of the Directive regarding Machines).

VE.L650

Kit of flashing lights to the installed onto the arm.

VE.RAST

Aluminium rack

VE.SN500

Joint for arm

Warning:

If VE.RAST is installed, the use of SC.RES is impaired and viceversa.

8) BALANCING (FIG. 6)

For a good road gate operation it is important that the rod is well balanced through the spring action. To check it proceed as follows:

• release mechanically the road gate through the release lever.

• start closing the rod and leave it; the rod will have to be positioned at about 45°.Repeat the operation by moving the rod towards the opening position.

If the balancing is not within the limits above mentioned act on the spring load through the nut D.

9) EMERGENCY MANUAL MANOEUVRE (FIG.7)

If there is no power supply or a fault, you can release the shaft and move it manually (Fig. 7).

The unlocking lever is found inside the barrier column;

• Lower the lever to release the shaft.

• Bring the lever back to its original position to reset automatic movement of the shaft.

10) MECHANICAL STOPS ADJUSTMENT (FIG.7)

With reference to Fig.5:

• Loosen the locking nut G

• Screw in/out mechanical stop F until the desired intervention position is obtained

• Fasten locking nut G

11) LIMIT SWITCH CAMS ADJUSTMENT (FIG.8)

The limit switch cams set the start and end points of the manoeuvres.

During the AUTOSET phase, the control unit saves the start points and end of stroke, the space and the slowing speed are set by the parameters TSMO/

TSMC SLDO/SLDC.

With reference to Fig.7:

• Unlock the shaft as indicated in the manual manoeuvre paragraph.

• Bring the shaft to the OPENING position O.

• Loosen fastening screw V of the opening limit switch cam.

• Adjust the cam so it intercepts the opening limit switch.

• Fasten cam fastening screw V.

• Bring the shaft to the CLOSURE position C.

• Loosen fastening screw V of the closure limit switch cam.

• Adjust the cam so it intercepts the closure limit switch.

• Fasten cam fastening screw V.

• Restore automatic operation.

12) CP.LADY CONTROL UNIT WIRE DIAGRAM

Wire connections shown in Fig. 12 are described hereunder:

SA.24V

TERMINALS

Function

Description

L-N-GND

Power supply

Mains input 100÷250Vac 50/60Hz

+ -

Output 24Vdc

Controller CP.1524 power supply output 24 Vdc

+ BAT-BAT

Batteries

Clamp input for connection of back-up batteries (accessory).

CP.LADY

TERMINAL BLOCK M1

M1

24Vdc INPUT

24Vdc input for powering the CP.LADY. In case of use of the SUN SYSTEM it is necessary to connect

the 24Vdc output of the SUN.SY to M1 (see the KSUN instructions)