1

9

e

l

u

d

e

h

c

S

d

e

d

n

e

m

m

o

c

e

R

e

r

u

d

e

c

o

r

P

e

c

a

n

e

t

n

i

a

M

s

t

n

e

n

o

p

m

o

C

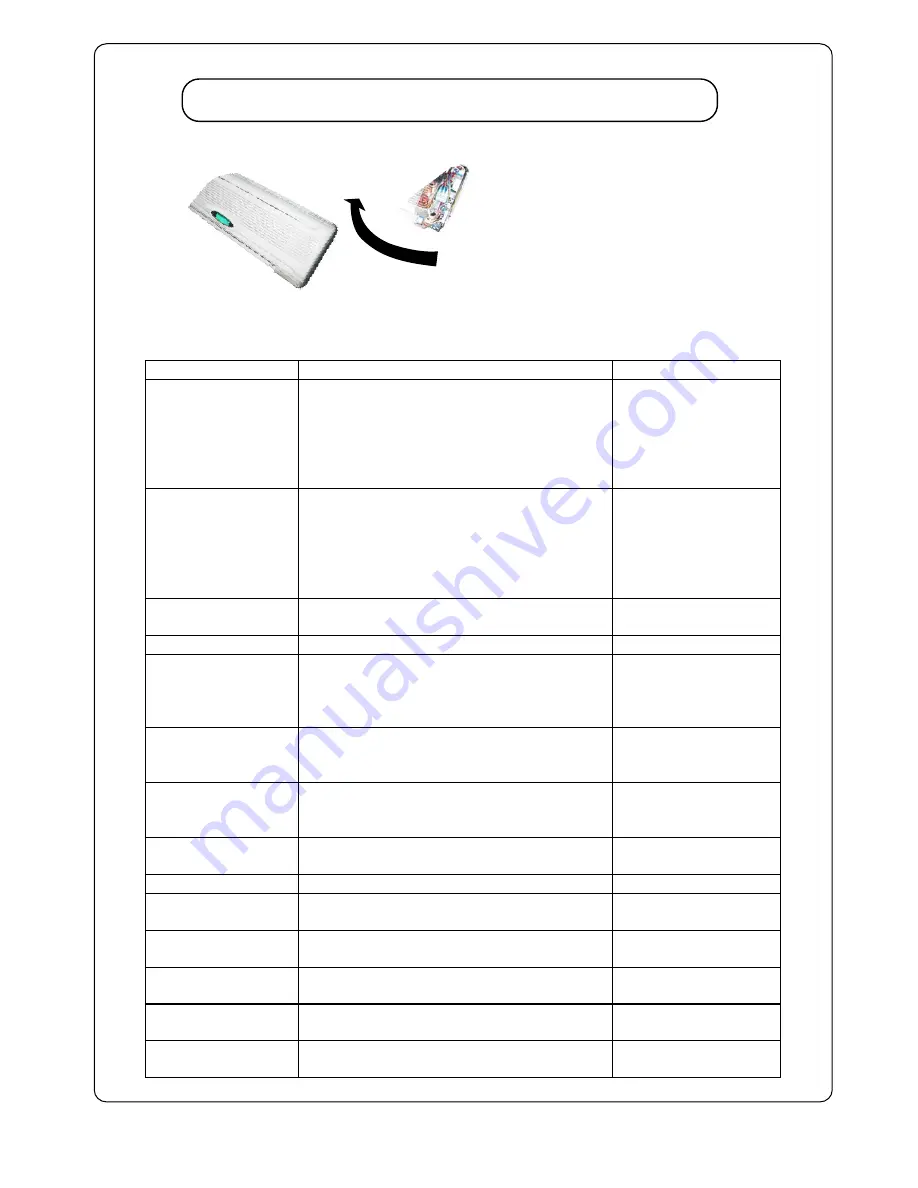

Air Filters

1.

Remove and

Clean with then washing in lukewarm

water (below 40

℃

) with

neutral soap.

2.Rinse well to dry before re-installing.

Note:Never use petrol,thinner,benzene or any

other

chemicals.

Every

1-2

months

.

More frequently if required.

Indoor Unit

1.Clean away dirt or dust on grille or panel by wiping

with a soft cloth soaked in lukewarm (or cold) water or

neutral detergent solution.

Note:Never use petrol,thinner,benzene or other

volatile chemicals,which may cause plastic surface

to

deform.

Every 2 weeks

More frequently if required.

Condensate Drain

Pan and Pipe

.

s

h

t

n

o

m

3

y

r

e

v

E

.

n

a

e

l

c

d

n

a

k

c

e

h

C

.

1

.

y

r

a

s

s

e

c

e

n

s

A

.

e

s

i

o

n

l

a

u

s

u

n

u

r

o

f

k

c

e

h

C

.

1

n

a

F

r

o

o

d

n

I

Indoor/OutdoorCoil

1.Check and remove dirt which are clogged between

fins.

2.Check and remove obstacles which hinder air flow in

and out of indoor/outdoor unit .

Every 2 months.

Electrical

1.Check voltage ,current and wiring.

2.Check faulty contacts caused by loose connections,

foreign matters,etc.

Every

1

2 months.

Every

1

2 months.

Compressor

1.No maintenance needed if refrigerant circuit remains

sealed.However,check for refrigerant leak at joints

and fittings.

Every

12

months.

Compressor Lubrication

1.Oil is factory charged .Not necessary to add oil if

circuit remains sealed.

No maintenance required.

Fan Motors Lubrication

1.All motors pre-lubricated and sealed at factory.

No maintenance required.

Tempering

valve

&

strainer

1.Valve function check & strainer cleaning.

Annually(more frequently if

required)

Pressure & temperature

relief valve

1.Pull the easing lever on valve to ensure water is

relieved to waste through the relief drain pipe.

Every 6 months

Sacrificial

Closed Circuit

Anode

1.Check

1.Check mixture lever

1.Every month

2.Every 12 months

2.Replace

Circulation Pump

1.Check abnormal noises bearing,Pump is sealed

Every 12 months

type

and replace if Necessary As per tank manufaturers

recommendations

7

.SERVICING AND MAINTENANCE

CAUTION:

After installing or servicing the unit,

please ensure that the front panel is

secured by the 1 hook undemeath

the front panel.

The unit is designed to give a long life operation with minimum maintenance required.However,

it should be regularly checked and the following items should be given due attention.

Summary of Contents for BENDX ACHW 34

Page 1: ...AIR CONDITIONER WATER HEATER OPERATION MANUAL...

Page 7: ...3 OUTLINES AND DIMENSIONS BENDX ACHW 34 BENDX ACHW 34 5...

Page 8: ...3 OUTLINES AND DIMENSIONS BENDX ACHW 41 BENDX ACHW 51 BENDX ACHW 41 BENDX ACHW 51 6...

Page 9: ...3 OUTLINES AND DIMENSIONS BENDX ACHW 65 BENDX ACHW 65 7...

Page 11: ...4 WIRING DIAGRAMS INDOOR UNIT OUTDOOR UNIT Model 34 41 and 51 Model 34 41 and 51 9...

Page 12: ...4 WIRING DIAGRAMS INDOOR UNIT OUTDOOR UNIT Model 65 Model 65 10...