1701ULTRA(EC)GBEN, p. 10/29

6

INSTALLING

WARNING

Check

the

supporting

structure

to

verify

that

it

has

sufficient

load

‐

carrying

capacity

to

support

the

unit

weight.

Suspend

the

heater

only

from

the

threaded

nut

inserts.

Do

not

suspend

from

the

heater

cabinet

panels.

Do

not

place

or

add

additional

weight

to

the

suspended

heater.

The

location

where

the

air

heater

is

to

be

installed

must

provide

sufficient

space

around

the

heater

for

servicing

and

clearances

for

safety

(see

figure

2).

When

the

unit

is

lifted

for

suspension,

leave

the

unit

on

the

pallet.

Before

hanging

verify

that

all

screws

originally

used

to

fix

the

shipping

supports

are

re

‐

screwed

into

the

cabinet.

Ensure

that

the

heater

is

installed

in

a

level

plane

and

vibration

free.

The

air

heater

must

be

fastened

securely

to

any

base

mounting

arrangement.

The

heater

is

supplied

with

four

point

suspension.

All

points

must

be

used.

Threaded

nut

inserts

are

provided

on

each

side

of

the

top

of

the

heater.

See

figure

4.

After

suspension

the

air

heater

should

be

rigid

so

as

to

avoid

placing

a

strain

on

the

flue

system,

gas

services,

electrical

wiring

and

duct

work.

1”

BSP

mounting

cap

nuts

are

optional.

In

case

of

a

type

C

installation,

the

distance

between

the

floor

and

the

underside

of

the

air

heater

must

be

at

least

1.70m.

Combustion

air

should

be

taken

from

a

height

that

exceeds

the

above

mentioned

height

of

1.70m.

Also

thermostats

and

switches

which

are

not

sparkless

have

to

be

installed

at

a

minimum

height

of

1.70m.

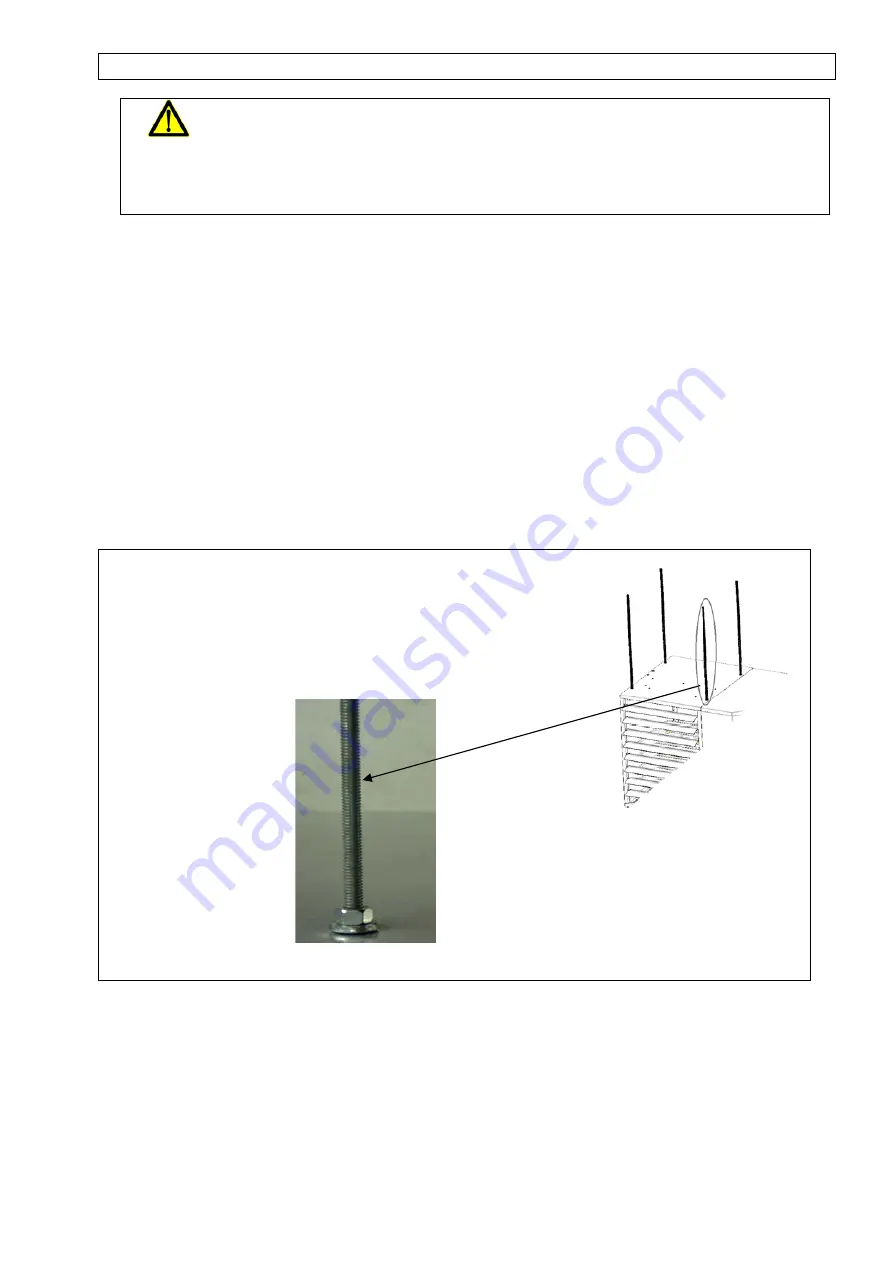

Figure

4

Be

sure

that

the

threaded

hanger

rods

are

locked

to

the

heater

as

illustrated

in

this

figure.

Recommended

maximum

hanger

rod

length

is

1.8m.

Where

longer

drops

are

required,

ensure

that

restraints

are

fitted

to

prevent

excess

lateral

movement

and

supports

are

adequately

sized.

Alternatively

the

unit

can

also

e

base

mounted

on

a

non

‐

combustible

support.

In

this

case

ensure

that

unit

is

securely

fixed

on

the

base.