1701ULTRA(EC)GBEN, p. 11/29

7

AIR

SUPPLY

&

FLUE

SYSTEM

7.1

GENERAL

WARNING

The

flue

must

be

in

accordance

with

all

international

and

national

rules

and

regulations

in

force.

Local

requirements

may

apply

in

addition

to

national

requirements.

Failure

to

provide

proper

flueing

could

result

in

death,

serious

injury

and/or

property

damage.

The

products

of

combustion

must

be

flued

to

outside

atmosphere.

Common

flues

(for

more

than

one

appliance)

must

not

be

used.

Single

wall

flue

pipe

exposed

to

cold

air

or

run

through

unheated

areas

should

be

insulated

to

avoid

condensation.

If

the

flue

passes

through

a

combustible

element

of

the

building

it

must

be

enclosed

by

a

sleeve

of

non

‐

combustible

material

and

separated

from

the

sleeve

by

at

least

a

25mm

air

break.

The

temperature

of

any

combustible

material

near

to

the

flue

must

not

exceed

65°C

when

the

heater

is

in

operation.

The

flue

must

be

at

least

50mm

away

from

any

combustible

material.

Provision

must

be

made

for

condensation

to

flow

freely

to

a

point

to

which

it

can

be

released,

i.e.

drain.

M

odel

ULTRA/ULTRA

EC

heaters

may

be

installed

as

type

B

or

type

C

installations.

The

unit

heaters

are

designed

to

operate

safely

and

efficiently

with

either

a

horizontal

or

vertical

flue

system

when

installed

according

to

the

specific

requirements

and

instructions.

If

this

heater

is

replacing

an

existing

heater,

be

sure

that

the

flue

is

of

the

correct

size

and

that

the

existing

flue

is

in

good

condition.

A

correctly

sized

flue

system

is

required

for

safe

operation

of

the

heater.

An

improper

sized

flue

system

can

cause

unsafe

conditions

and/or

create

condensation.

The

units

may

be

installed

as

a

balanced

flue

type

C

heater

requiring

both

a

combustion

air

inlet

pipe

and

a

flue

pipe

or

as

a

power

vented

heater

type

B

where

the

combustion

air

is

taken

from

the

space

where

heater

is

installed

and

which

requires

only

a

flue

pipe

exhausting

to

outdoors.

All

products

of

combustion

must

be

flued

to

outdoor

atmosphere.

E

ach

heater

installed

as

a

type

B

appliance

must

be

fitted

with

an

individual

flue

pipe

and

the

combustion

air

inlet

opening

must

be

provided

with

a

protection

grill.

E

ach

heater

installed

as

a

type

C

appliance

must

be

fitted

with

an

individual

combustion

air/flue

pipe

system.

Type

C2

appliance,

with

single

pipe

system

for

supply

of

combustion

air

and

evacuation

of

flue

gasses,

are

not

allowed.

For

testing,

the

flue

pipe

should

include

a

sealable

test

point.

Ideally

the

test

point

should

be

at

least

450mm

away

from

the

air

heater

flue

connection

socket.

However

if

a

concentric

flue

is

attached

directly

to

the

connection

sockets

then

the

combustion

should

be

tested

through

the

flue

outlet

collar

via

a

drilled

test

point

which

must

be

securely

plugged

on

completion.

F

ollow

the

flue

pipe

manufacturer’s

installation

instructions

for

making

joints,

including

connections

to

the

air

heater,

for

passing

through

a

building

element

and

for

support

requirements.

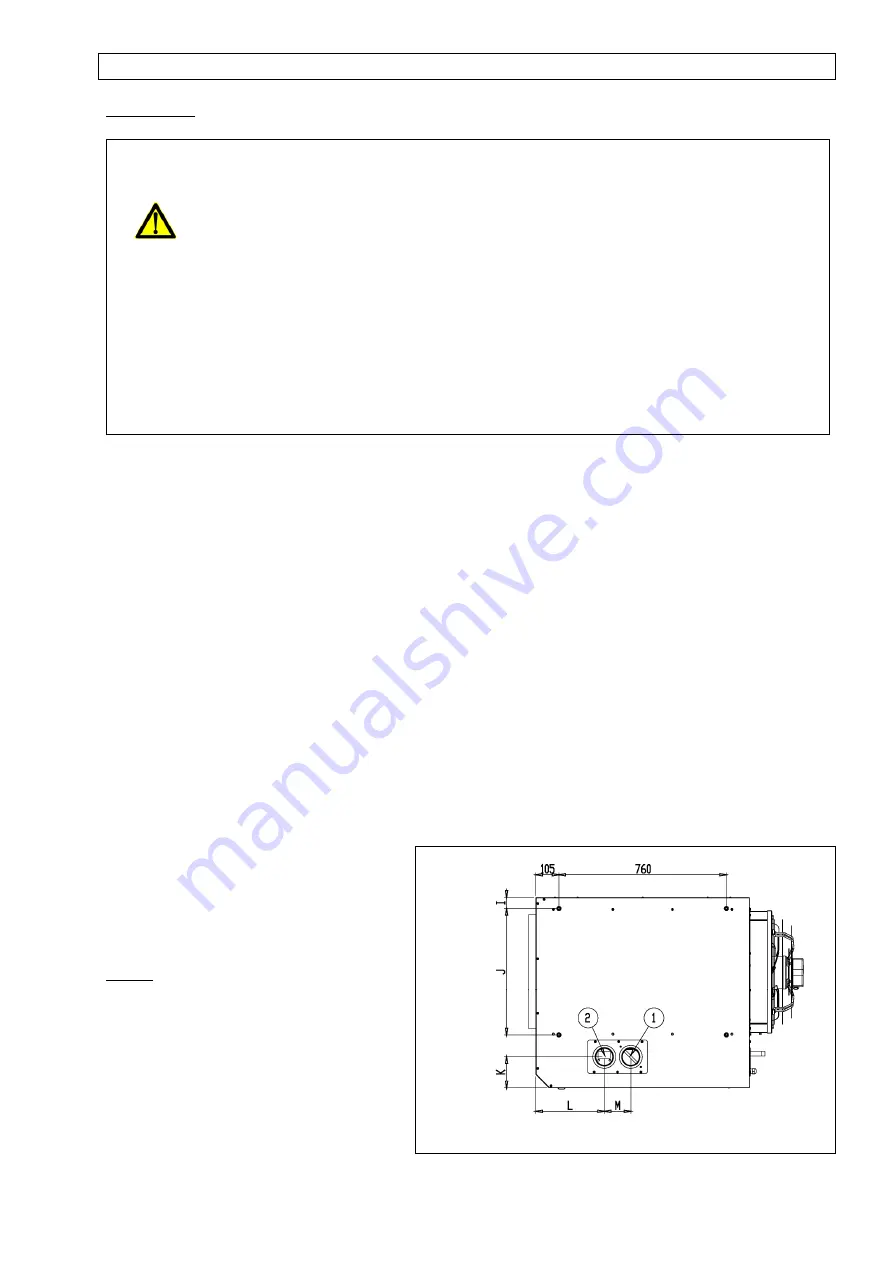

Figure

5

:

Combustion

air

and

flue

pipe

sockets

(standard

version)

Remark

:

A

cover

plate

can

be

installed

on

the

rear

or

top

panel.

The

plate

with

the

fresh

air

inlet

and

the

flue

outlet

socket

is

factory

installed

on

the

top

panel

but

can

easily

be

replaced

on

the

rear

panel

if

required.

In

case

of

change,

a

separate

kit

must

be

ordered

at

the

supplier.

Combustion

air

inlet

Flue

connection