1701ULTRA(EC)GBEN, p. 15/29

Proper

combustion

air

supply

for

a

power

vented

type

B

installation

requires

ventilation

of

the

heated

space.

Natural

infiltration

of

air

may

not

be

adequate.

Use

of

exhaust

fans

aggravates

this

situation.

It

is

important

to

ensure

that

there

is

adequate

combustion

air

supply

at

all

times.

Reliance

on

doors

and

windows

is

not

permitted.

Always

ensure

that

en

adequate

inlet

for

fresh

air

for

combustion

is

provided

sized

to

suit

the

total

installation

of

any

combustion

apparatus.

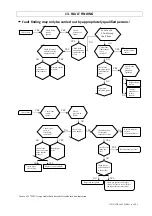

8

CONDENSATION

DRAIN

PIPE

CONNECTIONS

All

ULTRA/ULTRA

EC

units

are

designed

with

a

built

‐

in

siphon

(PN

70

61761)

(figure

9).

Attention

:

in

case

replacement

of

siphon

is

necessary,

ensure

that

siphon

is

correctly

installed.

(see

figure

10).

Figure

9

Figure

10

It

is

recommended

to

use

a

PVC

discharge

pipe.

The

condensation

connection

between

the

air

heater

and

the

siphon

has

a

32

mm

diameter

and

must

be

glued

(leak

proof)

onto

the

siphon

inlet.

To

ensure

the

condensation

water

does

not

freeze,

it

is

recommended

to

mount

the

drain

pipe

inside

the

building.

If

there

is

no

other

choice

but

mounting

it

outside,

it

is

strongly

recommended

to

equip

it

with

frost

proof

insulation.

When

connecting

the

siphon,

it

is

necessary

to

use

sealing

rings

(in

the

siphon

outlet).

Ensure

these

sealing

rings

are

correctly

mounted.

Condensation

drain

pipe

connections

must

be

glued,

to

prevent

condensation

water

dripping

from

the

drain

pipe.

If

you

want

to

open

the

siphon

(e.g.

to

clean

it),

the

air

heater

must

be

shut

down.

For

security

reasons

it

is

recommended

to

wear

gloves

when

cleaning

the

siphon.

The

siphon

has

to

be

cleaned

yearly

and

also

checked

for

metal

sludge.

In

the

event

that

there

is

a

lot

of

metal

sludge

present,

the

air

heater

must

be

serviced

more

frequently.

The

condensation

water

coming

from

the

air

heater

has

a

pH

‐

level

of

approx

4.6

and

can

affect

materials

made

from

zinc

and/or

copper.

Hence,

it

is

strongly

advised

against

letting

the

condensation

water

flow

off

through

the

gutter.

Condensation

water

does

not

belong

in

a

rain

‐

water

tank

!

Downstream

from

the

traps

the

condensate

drains

may

be

joined

and

both

must

be

connected

to

a

sanitary

drain

within

the

building.

Check

codes

to

be

certain

that

this

is

permitted

(condensate

from

the

heater

has

about

the

acidity

of

soda

pop

and

is

not

harmful

to

a

sanitary

drain).

ULTRA/ULTRA

EC

heaters

will

produce

condensate

depending

on

size

and

gas

type

(see

table

3).

A

condensate

disposal

system

that

relies

on

gravity

should

be

satisfactory

for

most

installations

since

unit

heaters

are

normally

installed

several

metres

above

the

floor.

If

a

gravity

system

is

not

possible,

a

condensate

pump

must

be

installed.

There

are

a

number

of

commercially

available

pumps

made

for

this

purpose.

If

using

a

condensate

pump,

follow

the

pump

manufacturer’s

installation

recommendations.

Table

3

:

Condense

drain

rates

of

flow

ULTRA/ULTRA EC

025

035

050

075

100

Natural gas/

Propane

l/h

1,2

1,3

1,8

2,1

3,7