1701ULTRA(EC)GBEN, p. 16/29

9

GAS

SUPPLY &

GAS

CONNECTION

We

refer

to

table

1

of

section

3

for

all

gas

specifications

WARNING

Connection

to

a

gas

service

installation

may

only

be

carried

out

by

suitably

qualified

persons.

The

gas

installation

must

comply

with

all

rules

in

force.

Only

materials

appropriate

for

gas

service

installation

may

be

used.

Do

not

rely

on

the

heater

to

support

the

gas

pipe.

NEVER

USE

A

FLAME

TO

TEST

FOR

GAS

SOUNDNESS.

ALL

COMPONENTS

OF

A

GAS

SUPPLY

SYSTEM

MUST

BE

LEAK

TESTED

PRIOR

TO

PLACING

EQUIPMENT

IN

SERVICE.

FAILURE

TO

COMPLY

COULD

RESULT

IN

PERSONAL

INJURY,

PROPERTY

DAMAGE

OR

DEATH!

9.1

GENERAL

ULTRA/ULTRA

EC

heaters

are

designed

to

operate

on

either

natural

gas

(G20),

propane

(G31)

or

butane

(G30)

gas.

Check

that

gas

supply,

gas

category

&

gas

inlet

pressure

is

in

accordance

with

the

data

described

on

the

air

heater

.To

let

the

unit

function

at

maximal

heat

output,

the

gas

supply

pipe

MUST

be

correctly

sized.

Close

to

the

air

heater

a

gas

tap

with

coupling

must

be

mounted

for

servicing

(see

figure

11).

It

is

strongly

recommended

to

place

a

gas

filter

and

clean

the

gas

tube

with

nitrogen.

The

whole

of

the

gas

service

installation

including

the

meter

must

be

inspected,

tested

for

soundness

and

purged

in

accordance

with

appropriate

requirements

by

a

qualified

person.

9.2

GAS

CONNECTION

9.3

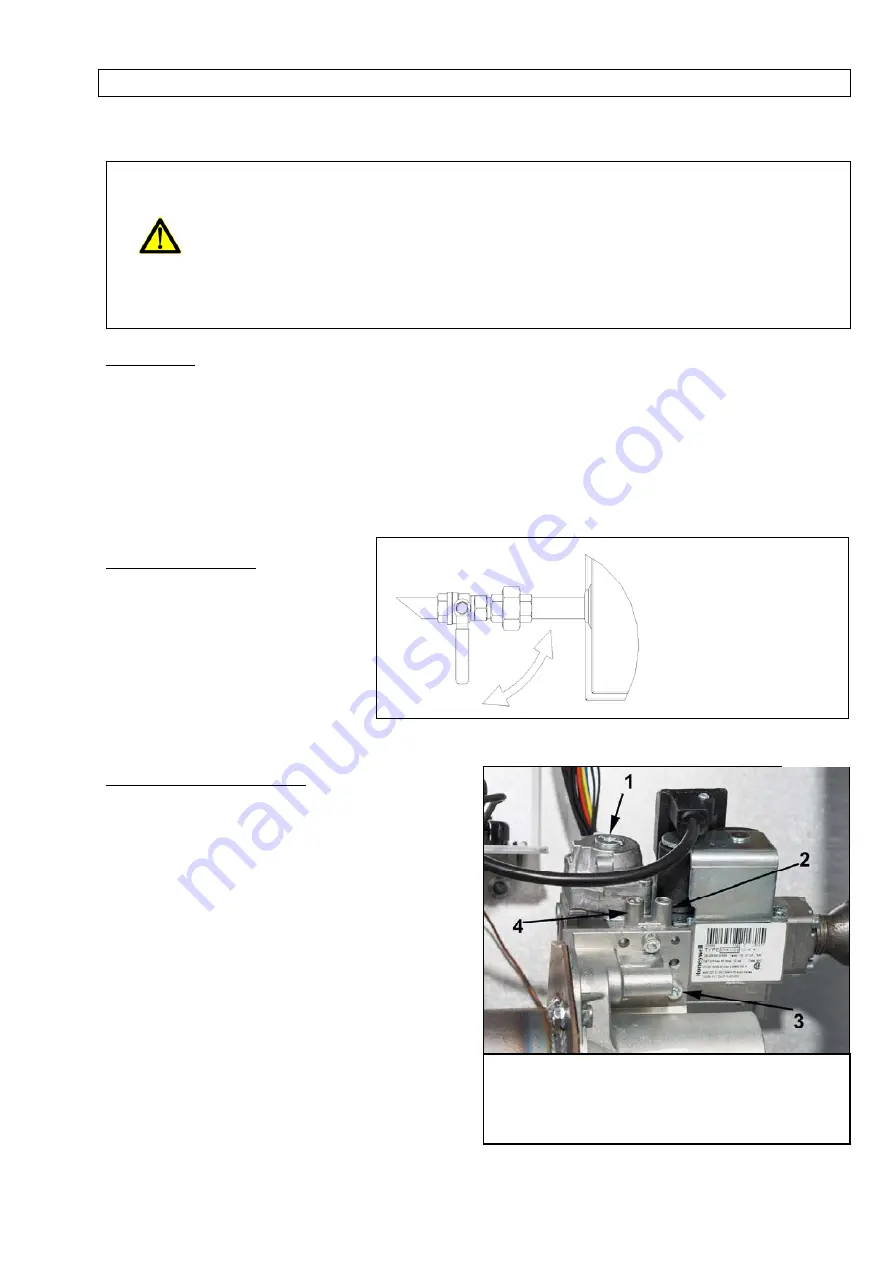

ADJUSTMENT

GAS

VALVE

To

adjust

the

offset,

remove

the

protection

screw

on

the

top

and

regulate

the

offset

by

using

the

exposed

screw.

Offset

values

will

be

measured

in

the

indicated

points.

To

adjust

the

CO

2

,

use

a

screwdriver

in

the

indicated

spot

and

turn

the

screw

driver

clockwise

to

decrease

the

measured

CO

2

or

turn

it

counter

clockwise

to

increase

the

measured

CO

2

.

The

CO

2

measurement

should

be

done

in

the

flue

discharge

pipe.

A

ll

units

are

set

according

to

the

data

plate

before

leaving

the

factory.

Any

modification

to

the

gas

valve

must

be

done

by

a

qualified

technician.

1

h

2

Inlet

pressure

measuring

point

3

CO2

adjustment

point

(throttle

)

4

Offset

measuring

point

REMARK

:

Do

not

over

tighten

and

do

not

rotate

the

gas

valve

inside

the

heater

control

compartmen

Figure

12

Figure

11