1704VRC3-AMEN, p 16/35

GENERAL

REQUIREMENTS

3.1

Related

documents

It

is

important

that

all

gas

appliances

are

installed

in

accordance

with

the

rules

in

force

and

by

appropriately

qualified

persons.

Failure

to

install

appliances

correctly

could

lead

to

prosecution.

It

is

in

your

own

interest

and

that

of

safety

to

ensure

compliance

with

the

law.

Air

heaters

should

not

be

installed

in

corrosive

atmospheres,

i.e.

near

plating

or

degreasing

plants

or

in

areas

where

there

is

a

fire

risk.

Do

not

locate

the

air

heater

where

it

may

be

exposed

to

water

spray,

rain,

etc.

3.2

Heater

location

The

location

chosen

for

the

air

heater

must

permit

the

provision

of

a

satisfactory

flue

system

venting

to

outdoor

atmosphere

and

adequately

ventilated

to

provide

for

combustion

air.

The

location

must

also

provide

sufficient

space

to

allow

the

heater

to

be

serviced.

Table

3

Minimum

installation

clearances

(mm)

Table

4 Recommended mounting

heights

(m)

(*)

*

Measure

rear

clearance

from

the

back

of

the

motor

*

Height

from

floor

to

bottom

surface

of

heater.

These

are

recommendations

only.

Positioning

of

heaters

depends

on

application.

Air

heaters

should,

where

ever

possible

always

be

installed

to

blow

toward

or

along

external

wall

surfaces.

Where

two

or

more

air

heaters

are

installed

in

the

same

room,

a

general

scheme

to

ensure

continuous

air

circulation

should

be

maintained

for

best

results.

Suspended

heaters

are

most

effective

when

located

as

close

to

the

occupancy

zone

as

possible,

this

fact

should

be

born

in

mind

when

determining

the

mounting

heights

to

be

used.

Care

should

be

exercised

to

avoid

directing

warm

air

directly

onto

the

occupants.

Partitions,

columns,

counters,

storage

racking,

etc.

should

be

taken

into

account

when

choosing

the

location

so

that

an

unobstructed

path

for

the

air

circulation

can

be

maintained.

Where

air

heaters

are

located

in

the

centre

of

the

space

to

be

heated,

the

air

should

be

discharged

toward

outside

walls.

In

large

areas,

they

should

be

located

to

discharge

air

along

outside

walls

with

additional

heaters

provided

to

blow

air

into

the

centre

of

the

area.

In

places

where

infiltration

of

cold

is

excessive,

such

as

entrance

doors

it

is

desirable

to

locate

a

heater

so

that

warm

air

is

discharged

directly

toward

the

source

of

cold

air

from

a

distance

of

4,5

‐

6,0

metres.

3.3

Combustion

air

supply

&

flue

system

The

air

heater

may

be

installed

as

a

balanced

flue

(Type

C)

heater

requiring

both

a

combustion

air

inlet

duct

and

a

flue

pipe

or

as

a

power

vented

(Type

B)

heater,

which

requires

only

a

flue

pipe

exhausting

to

outdoors.

All

products

of

combustion

must

be

flued

to

outdoor

atmosphere.

Each

heater

installed

as

a

type

B

appliance

must

be

fitted

with

an

individual

flue

pipe

and

the

combustion

air

inlet

opening

must

be

provided

with

a

protection

grill

(ask

your

distributor

for

the

appropriate

protection

grill

(IP20)

(dia130

=

PN

02

25094

).

Each

heater

installed

as

a

type

C

appliance

must

be

fitted

with

an

individual

combustion

air/flue

pipe

system.

Only

systems

specified

by

the

air

heater

manufacturer

may

be

used.

Common

flue

and

combustion

air

systems

must

not

be

used!

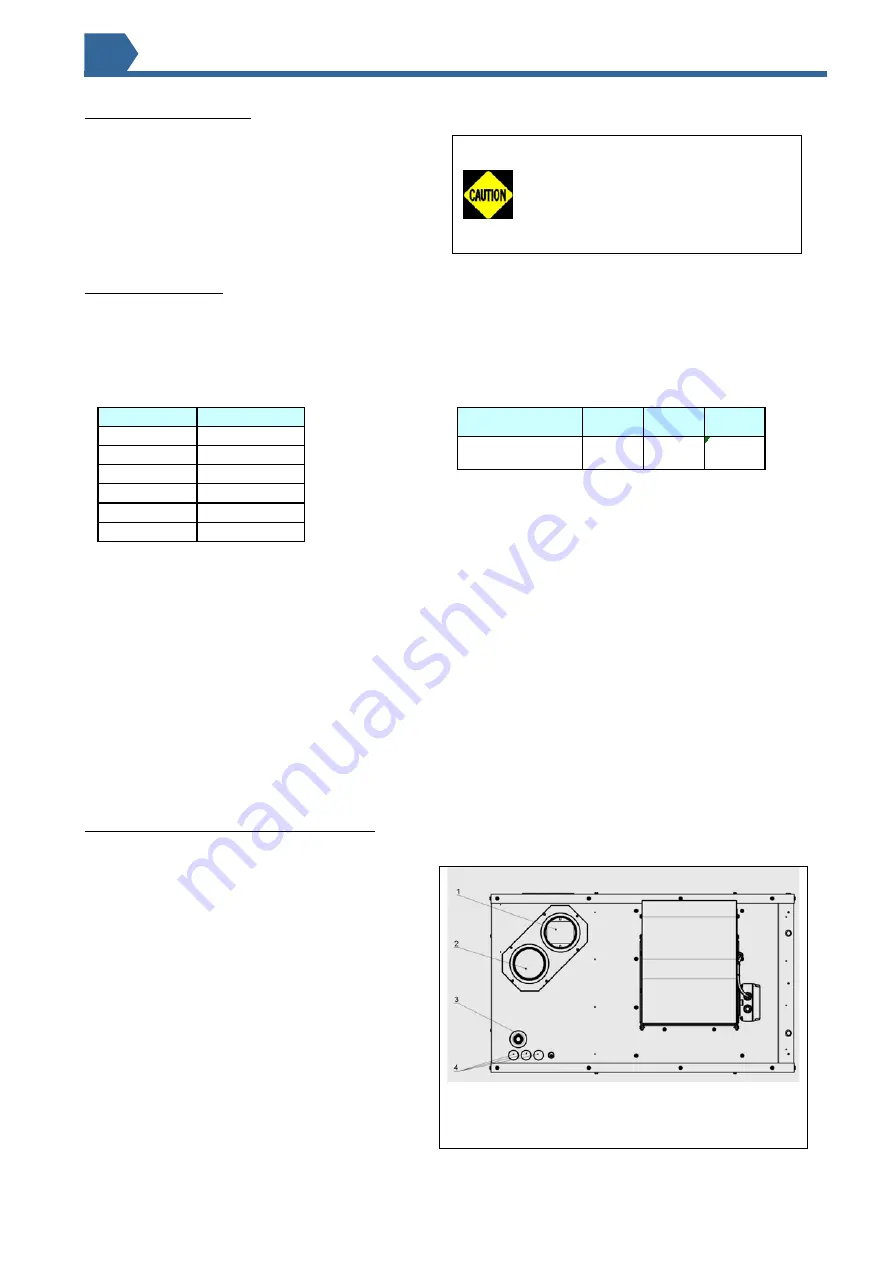

Figure

2a

:

Combustion

air

and

flue

pipe

sockets

1

Flue

outlet

socket

2

Combustion

air

inlet

opening

3

Gas

connection

inlet

with

sealing

ring

4

Electrical

connections

3

VRC-3

20

30

45

others

Mounting height

3

4

5

VRC-3

100

Top

150

Flue connector

150

Access panel

500

Non access sid

150

Bottom

150

Rear*

250

Summary of Contents for VRC-3 100-3

Page 5: ...1704VRC3 AMEN p 5 35 VRC 30 3 VRC 45 3 ...

Page 6: ...1704VRC3 AMEN p 6 35 VRC 60 3 VRC 75 3 ...

Page 8: ...1704VRC3 AMEN p 8 35 VRC 30 3 with mix box VRC 45 3 with mix box ...

Page 9: ...1704VRC3 AMEN p 9 35 VRC 60 3 with mix box VRC 75 3 with mix box ...

Page 11: ...1704VRC3 AMEN p 11 35 VRC 30 3 with mix box and filters VRC 45 3 with mix box and filters ...

Page 12: ...1704VRC3 AMEN p 12 35 VRC 60 3 with mix box and filters VRC 75 3 with mix box and filters ...

Page 14: ...1704VRC3 AMEN p 14 35 2 5 Dimensions STANDARD UNIT ...

Page 15: ...1704VRC3 AMEN p 15 35 UNIT WITH MIXING CABINET option 526 ...