P

ag

e

65

adversely affect the rotor to operate in a non-linear

region causing the coefficients to be inaccurate. If

the trial weight causes the amplitude to change

more than 200%, it is considered that the trial

weight to be too much and will need to be reduced.

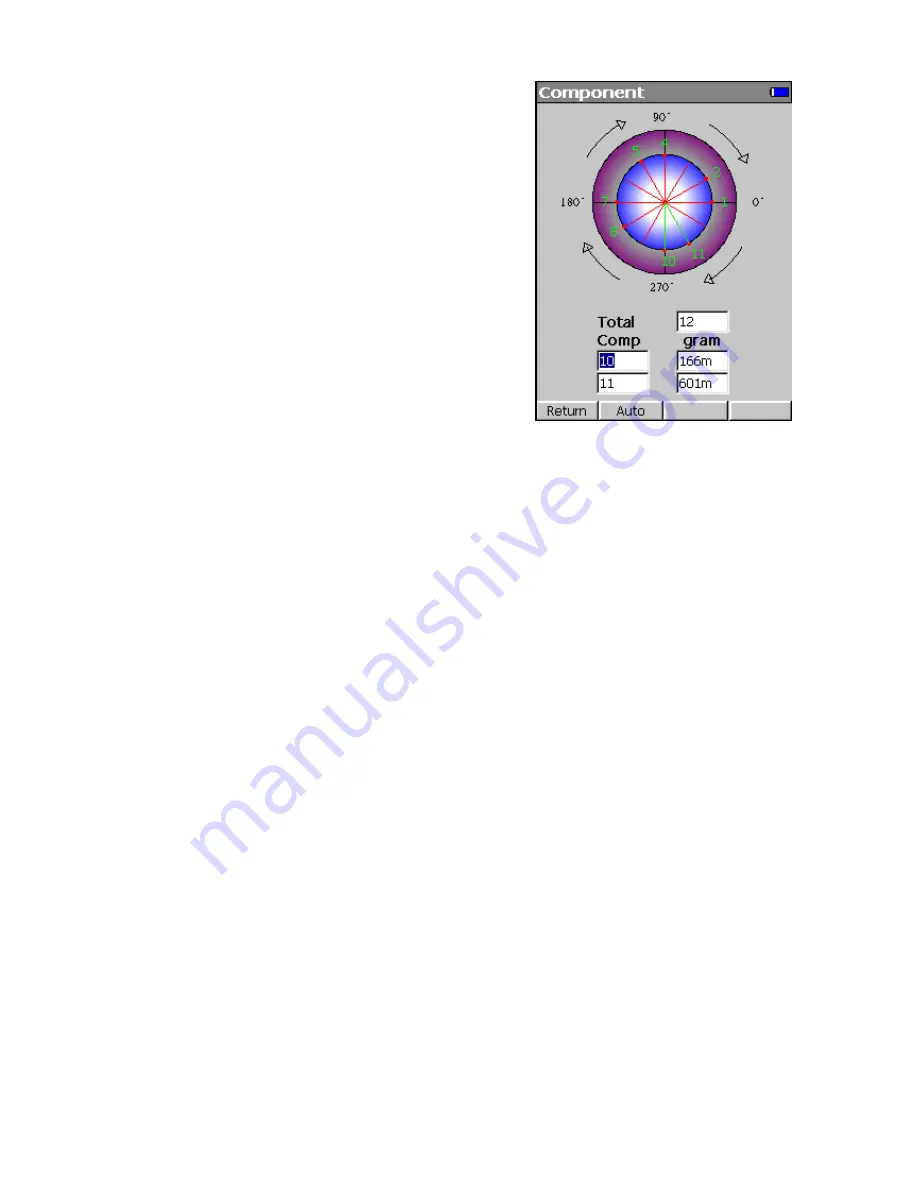

Position

: Enter the position where you plan on

adding or cut the trial mass.

If there is no special consideration, it is

recommended to place the trial mass at 0 degree

for convenience.

For your safety:

Sometimes the original

imbalance of a rotor is very large, and may cause a hazard if one happens to

place the trial weight on the heavy spot of the rotor- thus increasing the unbalance.

To prevent this from happing, a good estimate of the trial weight may be necessary.

By referencing the phase angle of the original measurement one can reduce this

risk by placing the trial weight not on the high spot, because the phase derived by

Fieldpaq is absolute “high spot” phase.

If the rotation of the machine has a rigid foundation and is rotating at low speeds

(lower than the first critical speed), the location of its heavy spot would be on the

same position of displacement phase. For example, if you measure the

vibration in displacement unit (mil) and got the phase reading

θ

degree, then

you know that the heavy spot of the rotor is in the neighborhood of

θ

degree. So

it is recommended to place the trial weight at (

θ

+180) degree because the trial

weight will reduce the vibration level and maintain a safer operation.

If the vibration is taken in velocity, then the high spot position is at (

θ

-90) degree.

If the vibration is taken in acceleration, then the high spot position is at (

θ

-180)

degree. If you are not sure if your phase guessing is correct or not, you may

need to perform a coast down test with the order tracking program to examine the

phase lag of the machine, or consult a vibration expert to determine.

After

: Select Remove or Remain.

In general, it is recommended to remove the

trial weight after the trial measurement. In some cases, it is hard to recover the

trial mass, (by drilling a hold or welding a mass to the rotor, etc. ) then you have to

Summary of Contents for Fieldpaq

Page 5: ...Page 4 ...

Page 54: ...Page 53 Orbit x y ...

Page 61: ...Page 60 ...

Page 104: ...Page 103 Power Spectrum Time Waveform Bearing Spectrum ...

Page 199: ...Page 198 ...

Page 200: ...Page 199 DVF specifications Maximum frequency band Maximum resolution Maximum file size ...

Page 204: ...Page 203 Done ...

Page 206: ...Page 205 5 Start the Data Explorer Program 6 Select File Import ...

Page 215: ...Page 214 ...

Page 222: ...6 ...