Summary of Contents for R Type

Page 1: ...Handbook t rtr Ine BentleyR Type Number XIV Reprinted IWSW Pmduet Support Graphics Ltd 3l7 nt...

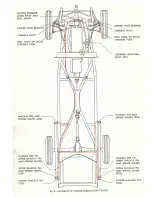

Page 37: ...Page36 DIAGRAM CHASSISLUBRICATION SYSTEM...

Page 38: ......

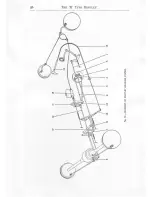

Page 40: ...Page38 DIAGRAM ENGINE LUBRICATION SYSTEM...

Page 41: ......

Page 59: ...Page55 BLANK PAGE...

Page 60: ...Tsn R Typr BrNrrBy...

Page 88: ...Page84 DIAGRAM ELECTRICAL WIRING...

Page 89: ......

Page 115: ...I I O TnB R Typu Bpxrrrv Fig 56 LUGGAGE BOOT SPARE WHEEL AND TOOL COMPARTMENT...

Page 119: ...CONVERSION TABLES AND FACTORS KILOMETRES_MILES OR MILES_KILOMETRES...

Page 122: ...w CONVERSION TABLES AND T ACTORS LITRES_PINTS OR PINTS LITRES Litres to LJ S Crallonsx 0 Zi4L7...