13

Bentone

165 205 44

3.6 Burner installation

3.6.1 Hole pattern

Make sure the hole pattern on the burner corr

esponds to the supplied fl ange

(refer to Technical data).

3.6.2 Burner installation

1.

Install the fl ange with gasket on the boiler.

2.

Fit the selected nozzle

(refer to Technical data).

3.

Install the brake plate and check the ignition electrodes

(refer to Burner Servicing).

4.

Mount the burner to the fl ange.

5.

Insulate between the burner and boiler door to reduce radiated heat (if

necessary).

3.6.3 Oil lines

1.

Check the dimensions of the oil lines (refer to Pump instructions).

2.

The oil fi lter should be fi tted to the incoming oil line. If a degasser is

installed, the oil fi lter should be fi tted to the oil line up to the degasser

in order to prolong the service life of the oil fi lter.

3.

For single pipe systems, the return plug must be removed

(refer to Pump instructions).

4.

When installing oil hoses, check that the supply and return hoses are

fi tted to the appropriate connection on the oil pump. The hoses must

be located so that they do not bend or become subject to tensile load.

5.

Bleed the oil system. Dry running will damage the oil pump.

6.

The vacuum in the suction line should not fall below 0,3 bar during

start-up.

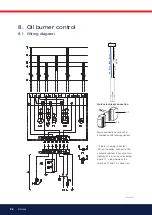

3.6.4 Electrical connection

If the boiler does not have a pre-fi tted connector, connect to the supplied

connectors (x2) as shown in the wiring diagram.

1.

Switch off the main switch.

2.

Connect the Europlugs (x2) as shown in the wiring diagram.

3.

Fit the Europlugs (x2) to the burner.

4.

Turn on the main switch.

3.6.5 Check oil line seals

Once the burner has been installed and commissioned, the seals of the

various coupling elements should be checked.

When a leak is detected, it is usually suffi cient to tighten the coupling

element that is leaking.

Return

Supply

X1

X2

Summary of Contents for B 1 FUV 63-16

Page 31: ...171 905 28 ...

Page 34: ......

Page 35: ......

Page 36: ...Enertech AB P O Box 309 SE 341 26 Ljungby www bentone se www bentone com ...