172 305 25 07-01

Flame monitoring and measure-

ment of ionisation current

The burner is monitored according

to the ionisation principle. Check the

ionisation current on start-up and on

each service call.

The reason for a low ionisation current

may be leaking currents, bad connec-

tion to earth, dirt or a faulty position

of the flame electrode in the burner

head. Sometimes also a faulty gas/air

mixture may cause too weak a ionisation

current.

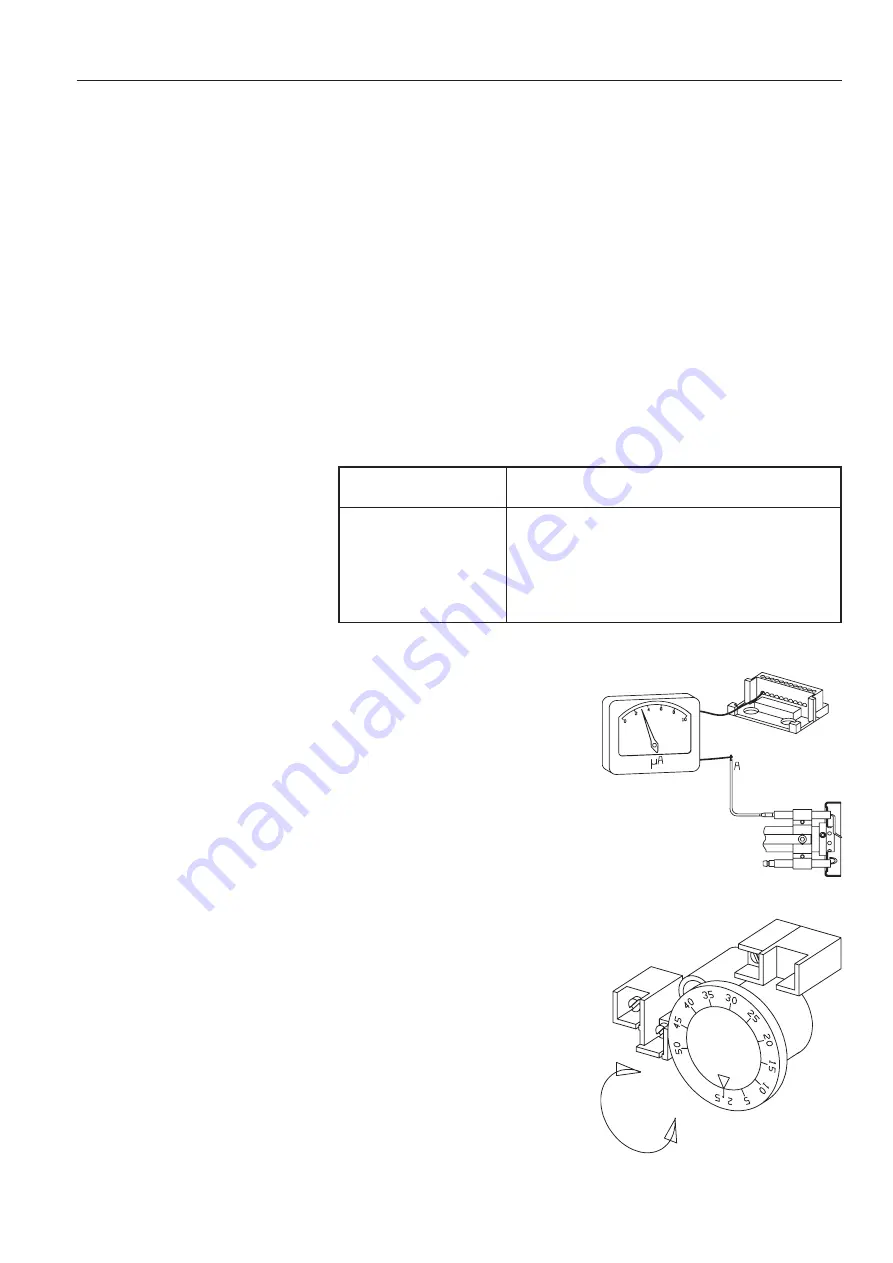

The ionisation current is measured

by means of a microampere meter

(µA) connected in series with the

flame electrode and the gas burner

control.

Connect the µA-meter, see figure. Min.

required ionisation current according

to table. In practice this current must

be considerably higher, preferably

more than 10 µA. All the gas burners

are equipped with a ionisation cable

that can be slit which facilitates the

connection of the µA-device.

Gas pressure switches:

Adjustment range:

2,5-50 mbar GW 50

5-150 mbar GW 150

Adjustment of min. gas pressure

switch

The min. pressure switch should react

if the gas pressure is too low and

prevent the burner from starting. Too

low a gas pressure during operation

should stop the burner. The burner

may start again when the rated gas

pressure has been reached.

Remove the protective cover. Connect

a pressure gauge for measuring the

rated pressure. Decide on pressure

at which the gas switch should switch

off. Set this pressure by means of the

valve. Carefully turn the knob (see

figure) until the gas pressure switch

switches off. The value shown on the

scale should then approximately cor-

respond with the value shown on the

pressure gauge. Tolerance on scale

appr. ± 15 %. Open the ball valve.

GENERAL INSTRUCTION

Adjustemnt of max. gas pressure

switch

The burner is equipped with a max.

gas pressure switch only on request.

It should stop the burner if the gas

pressure exceeds the set value. The

burner can then only be re-started

manually (gas burner control or

overpressure switch).

Remove the protective cover. Connect

a pressure gauge for measuring the

rated gas pressure. Decide on pres-

sure at which the gas pressure switch

should switch off. Turn the adjustment

knob to this value. Tolerance on the

scale ±15%.

Adjustment of air pressure switch

The air presure switch should stop the

burner if the air volume is reduced.

The air proving device shall be adjusted

in such a way that if there is insufficient

air supply at the highest or lowest

burner operating stage, the device

operates before the supervised pres-

sure is less than 80% of the pressure

at the controlled stage and the CO

content of the combustion products

exceeds 1% by volume.

Air pressure switch:

Adjustment range ca:

1-10 mbar LGW 10

2,5-50 mbar LGW 50

Flame monitoring

Gas pressure switch, air pressure

switch

Gas control

Connection to terminal

in gas control

Min. ionisation

current required

LMG

1

2 µ A

LGB

1

10 µ A

LFL

24

10 µ A

MMI 810

2

5 µ A

TMG 740-3

1

5 µ A